Service life based high-temperature container creep fatigue strength design method

A pressure vessel and fatigue strength technology, applied in the field of creep fatigue strength design of high temperature pressure vessels, can solve the problems of conservative R5 evaluation conclusion, inability to realize high temperature structural design and strength check, and cumbersome R5 analysis process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0219] This embodiment only illustrates a specific implementation of the present invention, and does not limit other implementations of the present invention.

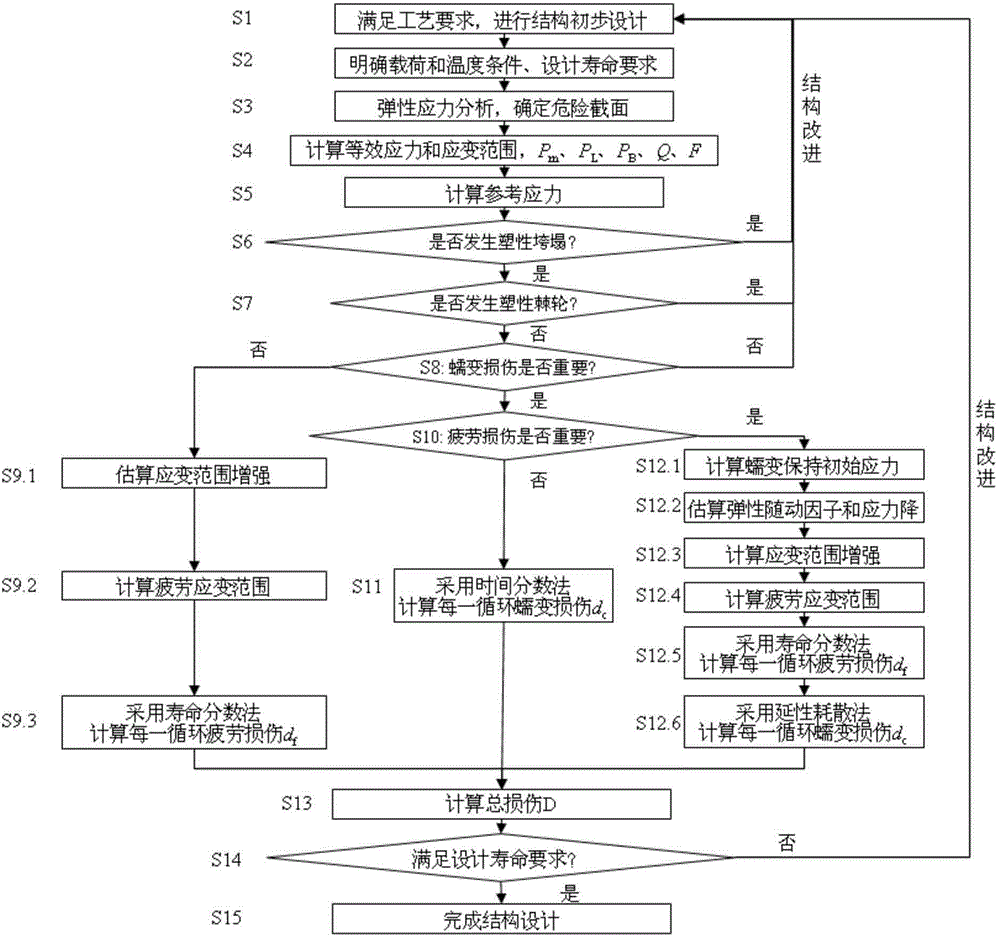

[0220] Taking a hydrogenation reactor as an example, according to a life-based design method for creep fatigue strength of a high-temperature pressure vessel of the present invention, the life-based structural design of the pressure vessel under a high-temperature environment is completed, and the specific steps are as follows:

[0221] S1 Carry out the preliminary design of the pressure vessel structure according to the process requirements such as design temperature and design pressure

[0222] The design parameters of the hydrogenation reactor are shown in Table 2, and the preliminary structural design is as follows Figure 5 shown.

[0223] Table 2 Design parameters of a hydrogenation reactor

[0224] Design pressure (MPa)

21.7

Design temperature (℃)

454

inner diameter(mm)

5200

T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com