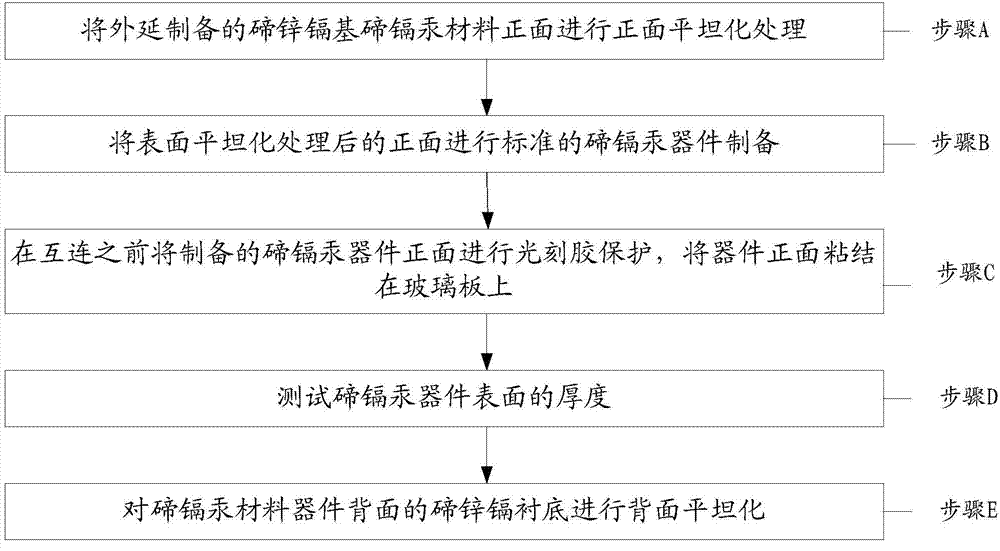

Method for planarization of double faces of mercury-cadmium-telluride infrared material device

An infrared material, mercury cadmium telluride technology, applied in the field of infrared detection, can solve problems such as wafer deformation, and achieve the effect of improving flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The HgCdTe material wafer size is 30mm×25mm, and the surface is ground with a diamond grinding wheel to remove the thickness of 3 microns, and then the grinding wheel damage is removed; after the standard HgCdTe device process, the photoresist is protected and then adhered to the glass plate with wax. The thickness difference between the maximum value and the minimum value of the test thickness is 7 microns, and the thickness is removed by diamond grinding wheel grinding to remove 10 microns, and the flatness of the tested mercury cadmium telluride device is 1.75 microns, which meets the interconnection requirements.

Embodiment 2

[0037] The HgCdTe material wafer size is 30mm×25mm, and the surface is ground with a diamond grinding wheel to remove a thickness of 2.5 microns, and then the grinding damage of the grinding wheel is removed; after the standard HgCdTe device process, the photoresist is protected and then adhered to the glass plate with wax. The thickness difference between the maximum value and the minimum value of the test thickness is 6 microns, and the thickness is removed by diamond grinding wheel grinding to remove 10 microns, and the flatness of the HgCdTe device is 1.55 microns, which meets the interconnection requirements.

Embodiment 3

[0039] The HgCdTe material wafer size is 36mm×38mm, and the surface is ground with a diamond grinding wheel to remove a thickness of 5 microns, and then the grinding wheel grinding damage is removed; after standard HgCdTe device technology, the photoresist is used to protect and adhere to the glass with epoxy glue On the board, the thickness difference between the maximum value and the minimum value of the test thickness is 11 microns, and the thickness of 15 microns is removed by single-point diamond turning, and the flatness of the HgCdTe device is 1.95 microns, which meets the interconnection requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com