Slag discharge system, gasifier and gasification power generation device

A slag and gasifier technology, applied in the field of gasification power generation devices, can solve the problems of installation of auxiliary equipment such as syngas cooler 71, increase in construction cost, and increase in cost, so as to reduce maintenance costs, reduce failure rates, and reduce environmental pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

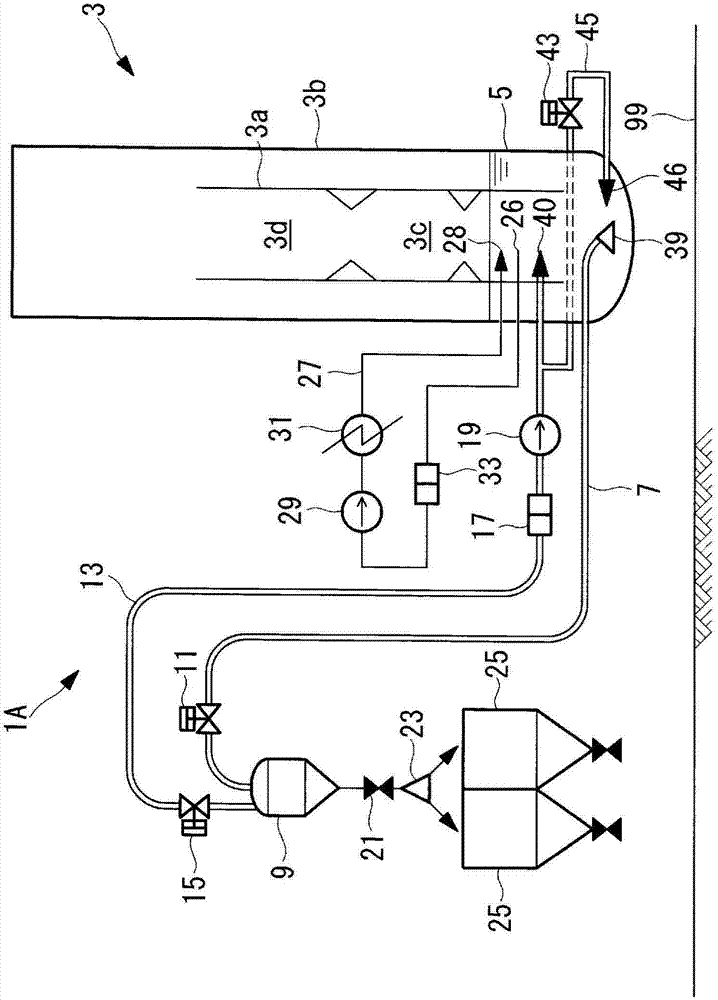

[0055] Below, use figure 1 The first embodiment of the present invention will be described.

[0056] figure 1 The slag discharge processing system 1A suitable for the coal gasification power plant (gasification power plant) which performs coal gasification combined power generation (IGCC: Integrated Coal Gasification Combined Cycle) is shown in .

[0057] The coal gasification power plant includes: a coal gasification device (gasification device) that gasifies coal powder (fine powder raw material) obtained by pulverizing coal (carbonaceous solid) with a mill or the like; a gas turbine (not shown), It is driven by combustion gas using combustible gas refined by the coal gasification device; a waste heat boiler (HRSG: Heat Recovery Steam Generator, not shown) that generates steam by passing the exhaust gas of the gas turbine; a steam turbine (not shown) is driven by steam generated by the exhaust gas boiler; and an electric generator (not shown) is powered by a gas turbine ...

no. 2 approach

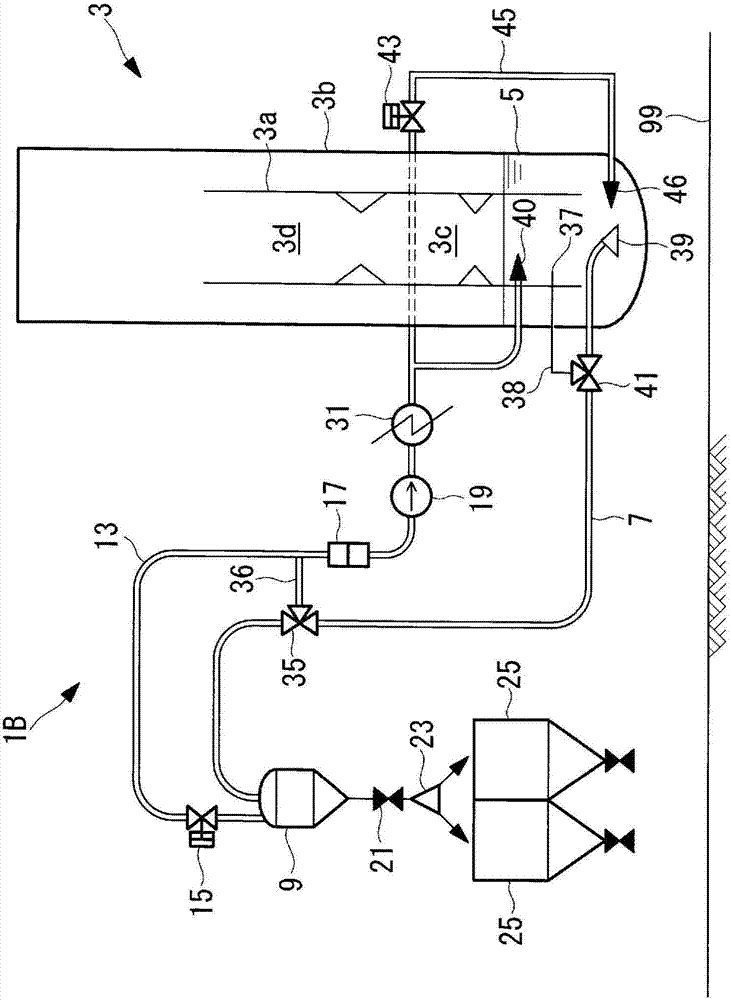

[0089] Next, use figure 2 A second embodiment of the present invention will be described.

[0090] In addition, the same code|symbol is attached|subjected to the same part as said 1st Embodiment, and detailed description is abbreviate|omitted.

[0091] The present embodiment is different in that the slag discharge line 7 and the water injection line 13 have the function of the cooling water circulation line 27 described in the first embodiment. thereby. In this embodiment, if figure 2 shown, omitted figure 1 Cooling water circulation line 27 is shown.

[0092] A bypass three-way valve (water flow direction switching mechanism) 35 is provided on the slag discharge line 7 . A bypass line 36 is connected to the bypass three-way valve 35 . The bypass line 36 connects the midway position of the slag discharge line 7 and the midway position of the water injection line 13 . The flow of cooling water directed from the slag hopper 5 to the slag discharge line 7 is switched by...

no. 3 approach

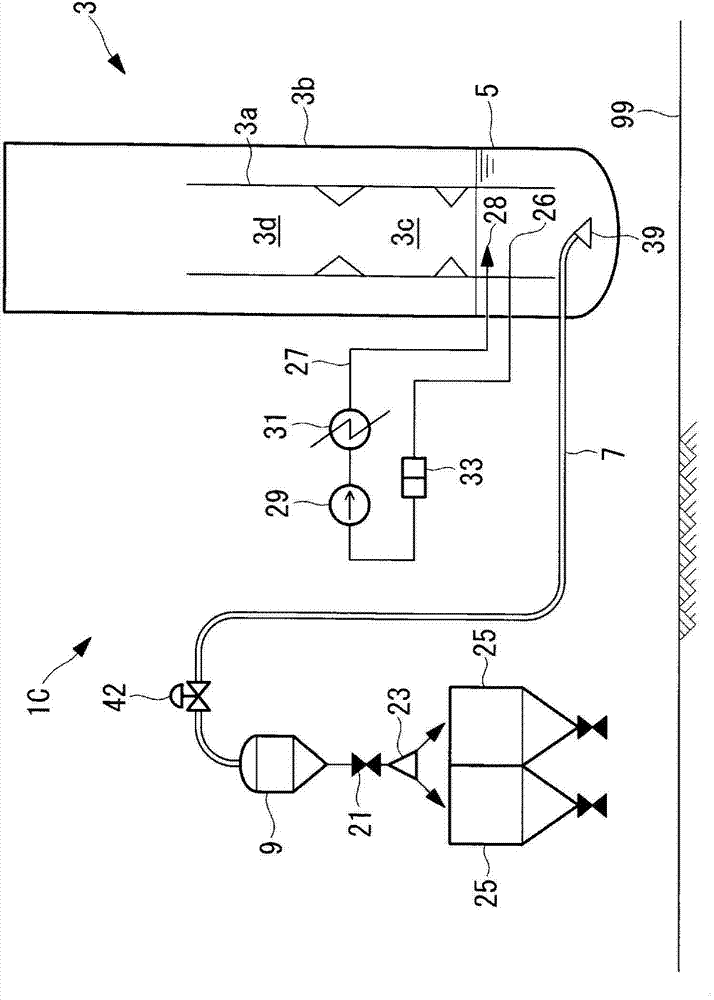

[0109] use image 3 , the third embodiment of the present invention will be described.

[0110] It should be noted that, for the above-mentioned first embodiment related figure 1 The same symbols are assigned to the same parts, and detailed description thereof will be omitted.

[0111] In the above-mentioned first embodiment and second embodiment, the following method is adopted, that is, the cooling water is injected into the slag hopper 5 from the water injection line 13 by the water injection pump 19, and the cooling water directed toward the lock hopper 9 is formed in the slag discharge line 7. However, in this embodiment, the flow of cooling water is formed in the slag discharge line 7 by using the pressure inside the gasifier 3 in a pressurized state without using the water injection pump 19 .

[0112] Such as image 3 shown, with the first embodiment of the figure 1 In comparison, they are the same in that the slag discharge line 7 is provided, but differ in that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com