Fermented deastringent coptis flower tea and preparation method thereof

A technology for removing astringency from Coptis chinensis is applied to the preparation of fermented and deastringent Coptis chinensis tea, and in the field of fermentation and deastringency Coptis chinensis tea.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

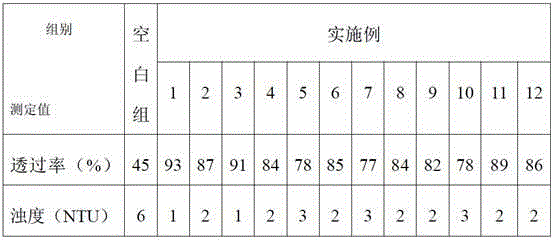

Examples

Embodiment 1

[0053] A fermented and deastringent Coptis chinensis tea is made from the following raw materials in parts by weight:

[0054] Raw material parts by weight

[0055] Coptidis 1000 parts

[0056] Cellulase 10 parts

[0057] Sodium chloride 80 parts

[0058] 20 parts of lactic acid bacteria.

[0059] A preparation method of fermented and deastringent Coptis chinensis tea, the steps are:

[0060] (1) Pick fresh Coptis chinensis in the flower bud stage, and pick out the flowers that are harmed by diseases and insect pests, rinse them with clean water, spread them loosely in a steamer, place them in a steam pot, and place them under the steam pressure of 0.1 or 0.2 or 0.3Mpa Time it for 2 minutes, and spread it in a cool place until the water content is 75%;

[0061](2) Cellulase is added in parts by weight of Coptis chinensis, the enzymolysis temperature is 25°C, the enzymolysis time is 4 hours; the enzymolysis environment humidity is 85%;

[0062] (3) Take the Coptis chinens...

Embodiment 2

[0065] A fermented and deastringent Coptis chinensis tea is made from the following raw materials in parts by weight:

[0066] Raw material parts by weight

[0067] Coptidis 1200 parts

[0068] Cellulase 60 parts

[0069] Sodium chloride 150 parts

[0070] 20 parts of lactic acid bacteria.

[0071] A preparation method of fermented and deastringent Coptis chinensis tea, the steps are:

[0072] (1) Pick fresh Coptis chinensis in the flower bud stage, and pick out the flowers that are harmed by diseases and insect pests, rinse them with clean water, spread them loosely in a steamer, place them in a steam pot, and place them under the steam pressure of 0.1 or 0.2 or 0.3Mpa Time it for 8 minutes, and spread it in a cool place until the water content is 90%;

[0073] (2) Cellulase is added in parts by weight of Coptis chinensis, the enzymolysis temperature is 30°C, the enzymolysis time is 6 hours; the enzymolysis humidity is 95%;

[0074] (3) Take the Coptis chinensis after e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com