Silver anode scrap washing complete device

A complete set of device and residual electrode technology, which is applied in the field of silver residual electrode washing complete sets of devices, can solve problems such as large corrosion hazards, and achieve the effects of saving water resources, improving cleaning time, and improving cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

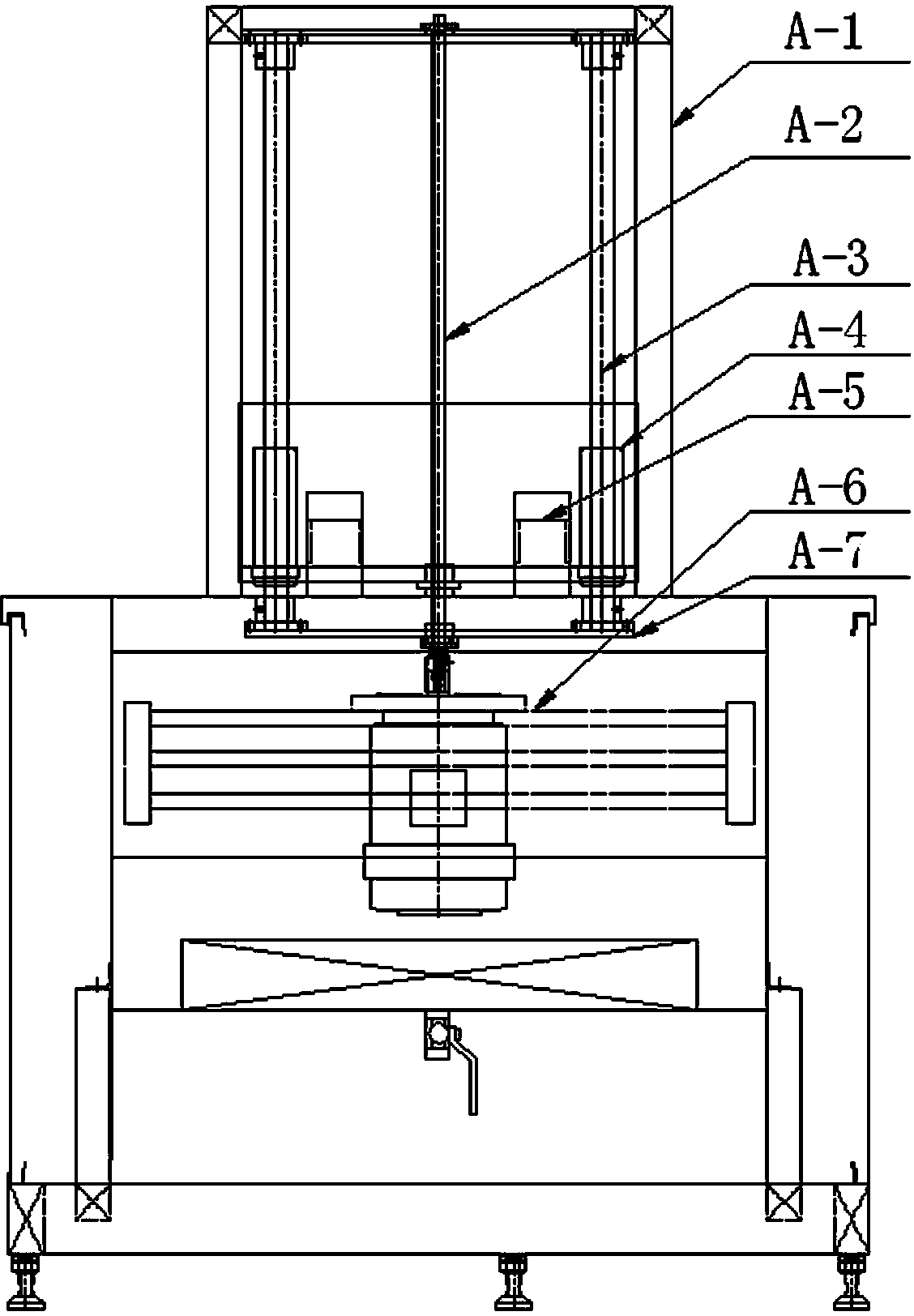

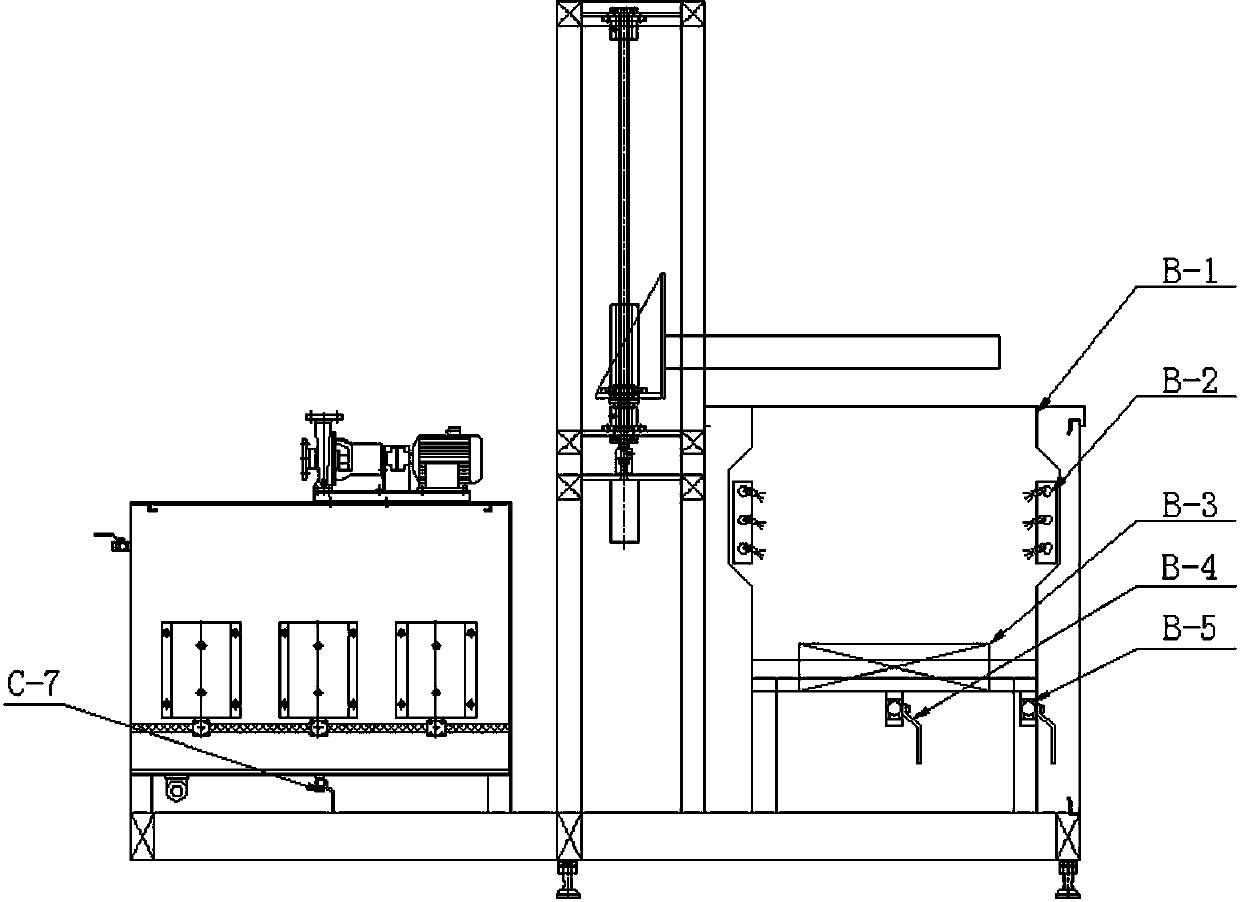

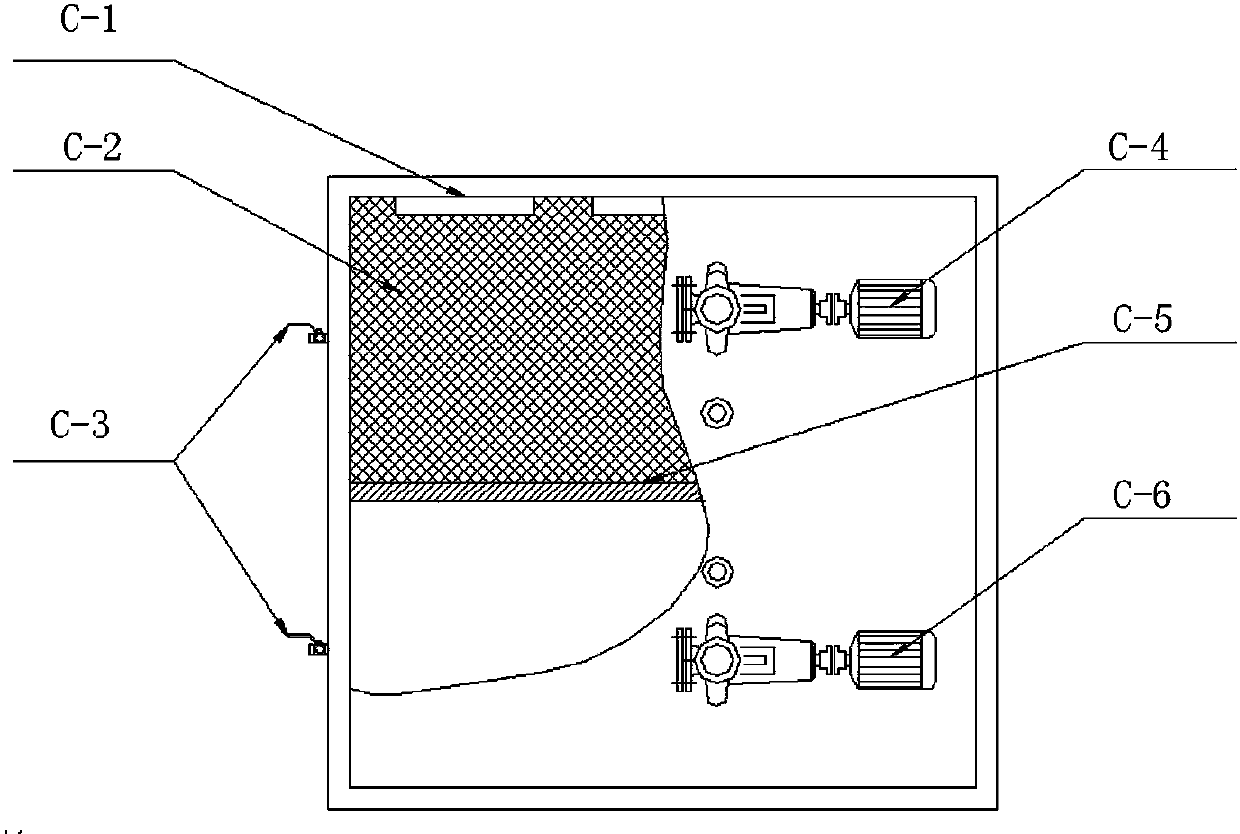

[0018] Such as figure 1 , figure 2 , image 3 As shown, a complete set of silver anode cleaning equipment is characterized in that the invention is characterized in that it consists of an anode remnant lifting mechanism A and an ultrasonic cleaning tank B located on both sides of the anode remnant lifting mechanism A and fixed on the same base, a water treatment Box C consists of three parts; among them:

[0019] The pole rack lifting mechanism A includes a lifting mechanism support frame A-1, a main transmission shaft A-2 located in the middle of the lifting mechanism support frame A-1, and a transmission worm A-3 arranged on both sides of the main transmission shaft A-2 , the upper and lower ends of the main transmission shaft A-2 cooperate with the transmission worm A-3 through the V-belt A-7, and the bottom end of the main transmission shaft A-2 is connected with the motor A-6; a driven module A-4 is set on the transmission The worm A-3 is engaged with the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com