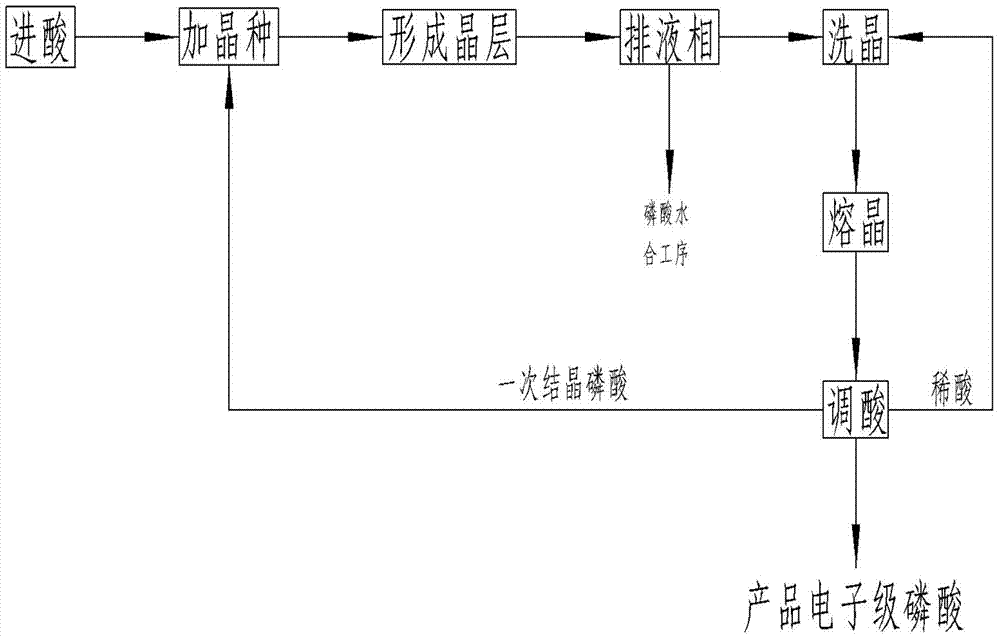

Method for preparing electronic grade phosphoric acid by use of septum type crystallization process

An electronic-grade phosphoric acid and crystallization technology, which is applied in the fields of phosphorus compounds, chemical instruments and methods, and inorganic chemistry, can solve the problems of low efficiency, complex electronic-grade phosphoric acid devices, and large energy consumption, so as to increase the area and reduce energy consumption , the effect of improving the crystallization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Firstly, beat the orthophosphoric acid with a temperature of 29°C and a concentration of 86% to the 1 / 2 liquid level of the crystal grid of the clapboard crystallizer, 2000kg of acid in 4 grids, and then inject -15°C brine into the cold and hot medium grids The phosphoric acid in the crystal lattice is cyclically cooled, and then the phosphoric acid semi-crystal seed is added into the crystal lattice from the seeding port according to 5‰ of the original phosphoric acid weight, so that the phosphoric acid semi-crystal seed induces phosphoric acid crystallization, and the phosphoric acid crystal begins to grow slowly , when the thickness of the crystalline layer gradually increases to 5cm, stop adding brine to the cold and hot medium cells, open the brine drain valve and liquid phase drain valve to drain brine and liquid phase, liquid phase dephosphoric acid hydration process, let stand for 30min to crystallize The residual liquid phase on the surface was dripped off, and ...

Embodiment 2

[0042] First, beat the orthophosphoric acid with a temperature of 29.5°C and a concentration of 87% to the 3 / 4 liquid level of the crystal lattice of the clapboard crystallizer, 3000kg of acid in 4 lattices, and then pour the brine at -8°C into the cold and hot medium lattice The phosphoric acid in the crystal lattice is cyclically cooled, and then the phosphoric acid semi-crystal seed is added into the crystal lattice from the seeding port according to 8‰ of the original phosphoric acid weight, so that the phosphoric acid semi-crystal seed induces phosphoric acid crystallization, and the phosphoric acid crystal begins to grow slowly. , when the thickness of the crystalline layer gradually increases to 5.5cm, stop adding brine to the hot and cold medium grid, open the brine drain valve and liquid phase drain valve to drain brine and liquid phase, liquid phase dephosphoric acid hydration process, let stand for 35min The residual liquid phase on the crystal surface was dripped of...

Embodiment 3

[0047] First, the outlet valve of the circulating acid of the acid adjustment tank is opened, and the molten acid sample with a temperature of 30°C and a concentration of 88% produced in Examples 1 and 2 is beaten to the crystal lattice 4 / 5 liquid of the clapboard crystallizer. At the location, 4 grids of acid total 3362kg, and then put -3 ℃ brine into the cold and hot medium grid to circulate and cool the phosphoric acid in the crystal grid, and then add semi-crystal seeds of phosphoric acid according to 10‰ of the weight of the original phosphoric acid Add the mouth into the crystal grid, so that the phosphoric acid semi-crystal seed induces phosphoric acid crystallization, and the phosphoric acid crystal begins to grow slowly. When the thickness of the crystal layer gradually increases to 6cm, stop adding brine to the cold and hot medium grid, open the brine drain valve and drain The phase valve is used to drain the brine and remove the liquid phase, and let it stand for 40 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com