Method for preparing potassium mixed salt mine by using nitrate contained magnesium sulphate subtype bittern and potassium nitrate production

A technology for magnesium sulfate subtype and potassium mixed salt ore, which is applied in the fields of producing potassium mixed salt ore and potassium nitrate by utilizing nitrate-containing magnesium sulfate subtype brine, can solve the problem of high content, achieve high energy consumption, high technology The effect of shortened process and serious equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

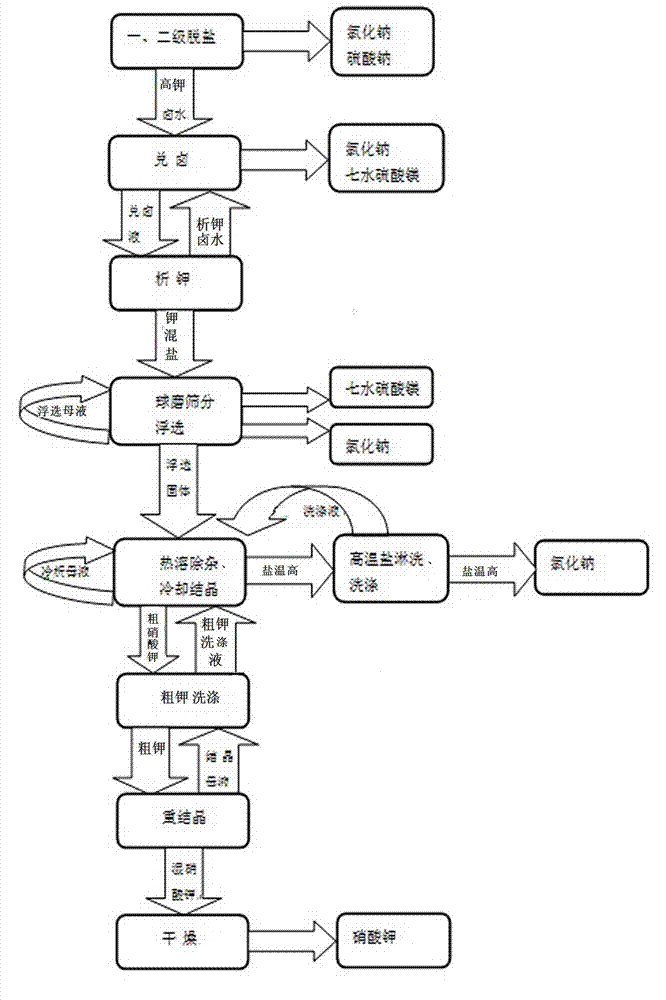

Method used

Image

Examples

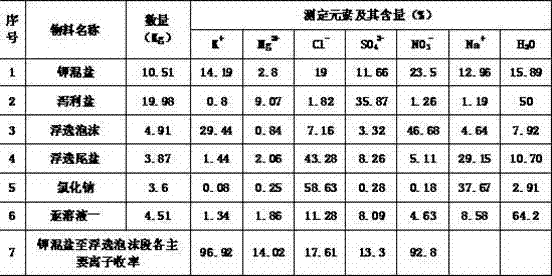

Embodiment 1

[0036] ① Preparation of potassium mixed salt:

[0037] First-level desalination: Take 1000Kg of intercrystalline brine from Uzunbulak Salt Lake, put it in multiple plastic basins with a diameter of 50cm and a depth of 20cm, and naturally evaporate and concentrate in the laboratory until the liquid phase contains 1.27% potassium. The drum is separated by a 40cm three-legged centrifuge. The separated solid phase is called sodium chloride here, and the sodium chloride content reaches more than 95%, which fully meets the requirements for the use of industrial salt. The separated liquid phase is called sulfuric acid here. Sodium saturated brine, which continues to undergo natural evaporation concentration desalination.

[0038] Secondary desalination: put sodium sulfate saturated brine in multiple plastic basins with a diameter of 50cm and a depth of 20cm, and concentrate it by natural evaporation until the liquid phase contains 2.05% potassium, using a three-legged centrifuge with...

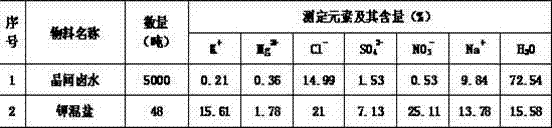

Embodiment 2

[0080] Embodiment two: The difference with Example 1 is only that, in the process of Example 1, during the process of adding brine, the mass ratio of high-sulfur brine: potassium-analyzed brine is 1:0.8, and this ratio is based on high-sulfur brine: potassium-analyzed brine in this embodiment. The mass ratio is 1:1.6 and the situation after carrying out is as follows:

[0081] Brine blending: according to the mass ratio of high-sulfur brine: potassium analysis brine is 1:1.6, blending and mixing evenly, and at the same time, a small amount of sodium chloride and magnesium sulfate are precipitated instantly. The blending solution is called brine blending solution here, and then The bittern solution is placed in multiple plastic basins with a diameter of 50 cm and a depth of 20 cm. It is naturally evaporated and concentrated in the laboratory until the liquid phase contains 3.36% potassium. It is separated by a three-legged centrifuge with a drum of 40 cm. The solid phase ...

Embodiment 3

[0085] Embodiment three: The difference with Example 1 is only that the brine used in the preparation process of potassium-analyzing mother liquor contains 2% potassium in the process ① of Example 1. In the present embodiment, the potassium-containing bittern used in the preparation process of potassium-analyzing mother liquor is 2.38% The situation after % is as follows:

[0086] Preparation of brine with potassium analysis brine:Take the brine that evaporates naturally from the salt field in the Uzunbulak Salt Lake area until the liquid phase contains 2.38% potassium, and put it in multiple plastic basins with a diameter of 47cm*35cm and a depth of 40cm, in a household Haier freezer, at -8 Freeze at ℃ for 48 hours, and then separate with a three-legged centrifuge with a drum of 40 cm. The separated solid phase is called ice nitrate, which is mainly sodium sulfate decahydrate containing a small amount of sodium chloride. The separated liquid phase is frozen nitrate After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com