Preparation method of high-elongation fluororubber F2311

A high-elongation, fluororubber technology, applied in adhesives, coatings, etc., can solve the problem of reducing the aging resistance, weather resistance, and corrosion resistance of fluororubber F2311 coatings, and it is difficult to improve the coating leveling effect, coating thickness, and sensitivity Problems such as surfactants, to achieve the effect of prolonging the polymerization reaction time, improving the van der Waals force, and prolonging the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

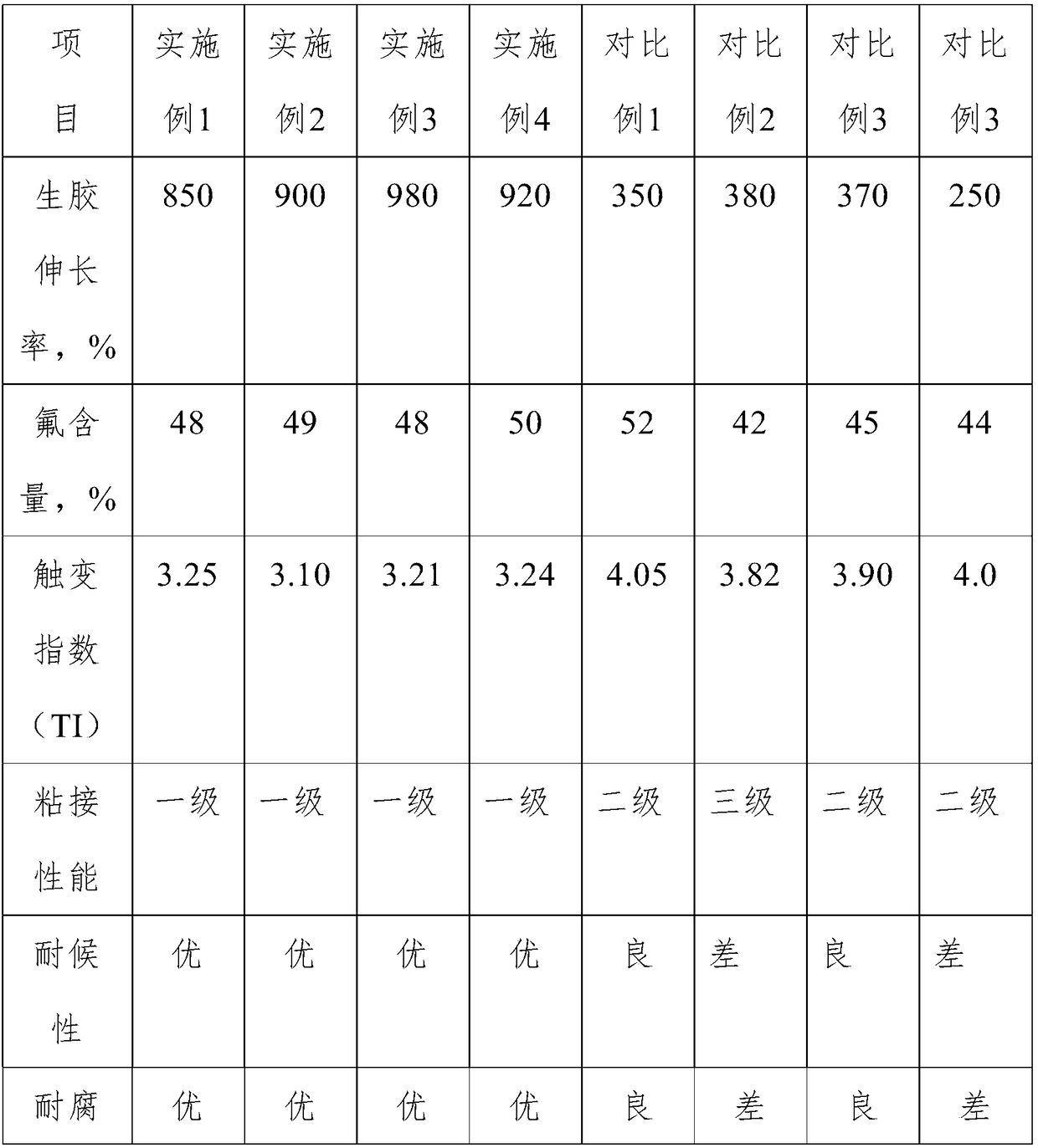

Examples

Embodiment 1

[0038] This embodiment relates to the preparation method of the fluororubber F2311 described in this application, comprising the following steps:

[0039] 1) Add 30L deionized water to the 50L reactor, and evacuate the reactor until the oxygen content is ≤30ppm;

[0040] 2) Add a mixed monomer of vinylidene fluoride and chlorotrifluoroethylene to the reaction kettle at a molar ratio of 1:1 until the pressure is 2.3Mpa, and when heated to a temperature of 60°C, add 3g of potassium permanganate and 1g of potassium bromide , 15g sodium hydroxide, 50g perfluoropolyether sodium carboxylate, start polymerization reaction;

[0041]3) During the reaction process, continue to add the mixed monomer of vinylidene fluoride and chlorotrifluoroethylene to maintain the pressure of the reactor at 2.3Mpa, and stop when the reaction time is 4.5 hours and the mixed monomer is fed about 8-10kg. Recover the unreacted monomer to the monomer storage tank, evacuate, release the emulsion, add a small...

Embodiment 2

[0043] This embodiment relates to the preparation method of the fluororubber F2311 described in this application, comprising the following steps:

[0044] 1) Add 30L deionized water to the 50L reactor, and evacuate the reactor until the oxygen content is ≤30ppm;

[0045] 2) Add a mixed monomer of vinylidene fluoride and chlorotrifluoroethylene to the reaction kettle at a molar ratio of 1:1 until the pressure is 1.8Mpa, and when heated to a temperature of 62°C, add 2g potassium persulfate, 1g sodium metabisulfite, 15g Borax, 45g ammonium perfluorooctanoate, start polymerization;

[0046] 3) During the reaction process, continue to add the mixed monomer of vinylidene fluoride and chlorotrifluoroethylene to maintain the pressure of the reactor at 1.8Mpa. After the reaction is completed, stop when the reaction time is 4.2 hours and the mixed monomer is fed about 8-10kg . Recover the unreacted monomer to the monomer storage tank, evacuate, release the emulsion, add a small amount...

Embodiment 3

[0048] This embodiment relates to the preparation method of the fluororubber F2311 described in this application, comprising the following steps:

[0049] 1) Add 30L deionized water to the 50L reactor, and evacuate the reactor until the oxygen content is ≤30ppm;

[0050] 2) Add a mixed monomer of vinylidene fluoride and chlorotrifluoroethylene to the reaction kettle at a molar ratio of 1:1 until the pressure is 2.0Mpa, and when heated to a temperature of 68°C, add 4g of succinic acid peroxide and 1g of brominated Sodium, 15g dipotassium hydrogen phosphate, 35g sodium perfluorooctanoate, start the polymerization reaction;

[0051] 3) During the reaction process, continue to add the mixed monomer of vinylidene fluoride and chlorotrifluoroethylene to maintain the pressure of the reactor at 2.0Mpa. After the reaction is completed, stop when the reaction time is 4.8 hours and the mixed monomer is fed about 8-10kg. . Recover the unreacted monomer to the monomer storage tank, evacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com