A method for treating acidic industrial wastewater with high sulfate and organic solubility

A technology for industrial wastewater and high sulfate content, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as poor water quality adaptability, small hydraulic load, secondary pollution, etc. , to achieve the effect of reducing the cost of chemicals, making the process more efficient and cleaning the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

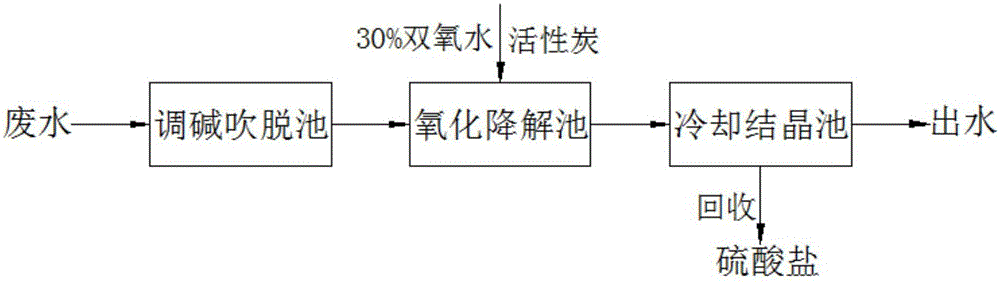

[0032] A Jiangsu chemical factory is mainly engaged in the production of salicylaldehyde, coumarin, polyurethane and composite materials. The wastewater discharged from it contains not only ultra-high solubility magnesium sulfate, but also a large amount of formaldehyde, methanol, phenol, and salicylaldehyde. and other organic matter. The wastewater has complex components and strong toxicity. It is a kind of strongly acidic sulfate organic wastewater. It is difficult to achieve effective treatment of this wastewater by using a single physicochemical or biological method. Adopt method step of the present invention as follows:

[0033] (1) The waste water is first collected in the alkali-adjusting blow-off tank, and the calculated amount of solid alkali (NaOH) is added to the waste water according to the volume and pH value of the waste water, and the stirring rate is controlled at 120r / min. And after the pH value of the wastewater rose to 2.3.

[0034] (2) After alkali adjust...

Embodiment 2

[0041] Waste water is with embodiment 1, adopts the concrete operating steps of the method of the present invention as follows:

[0042] (1) The waste water is first collected in the alkali-adjusting blow-off tank, and the calculated amount of solid alkali (NaOH) is added to the waste water according to the volume and pH value of the waste water, and the stirring rate is controlled at 120r / min. And the pH value of the waste water rose to 3.3.

[0043] (2) After alkali adjustment, the temperature of the wastewater is maintained at 70°C by heating, and then the wastewater is blown off for 40 minutes at an aeration intensity of 12L / min. The waste gas generated during the blowoff process will be collected in a combustion furnace in the factory Carry out combustion treatment; the diameter of the aeration head of the blow-off equipment used is 10mm, and the aeration aperture is 0.5mm.

[0044] (3) The wastewater after stripping is introduced into the oxidative degradation tank, the...

Embodiment 3

[0050] Waste water is with embodiment 1, adopts the concrete operating steps of the method of the present invention as follows:

[0051] (1) Wastewater is first collected in the alkali-adjusting blow-off tank, and the calculated amount of solid alkali (NaOH) is added to the waste water according to the volume and pH value of the waste water, and the stirring rate is controlled at 150r / min. And the pH value of the waste water was raised to 4.5.

[0052] (2) After alkali adjustment, the temperature of the wastewater is maintained at 85°C by heating, and then the wastewater is blown off for 30 minutes at an aeration intensity of 15L / min. The waste gas generated during the blowoff process will be collected in a certain combustion furnace of the factory Carry out combustion treatment; the diameter of the aeration head of the blow-off equipment used is 10mm, and the aeration aperture is 0.5mm.

[0053] (3) The waste water after stripping is introduced into the oxidative degradation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com