Controllable preparation method for three-dimensional nano self-assembly of copper oxide

A nano-self-assembly and three-dimensional nano-technology, applied in the direction of copper oxide/copper hydroxide, nanotechnology, etc., can solve problems such as unsuitable for large-scale application, complex synthesis process, expensive reaction equipment, etc., and is conducive to large-scale application , low preparation cost, significant production practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

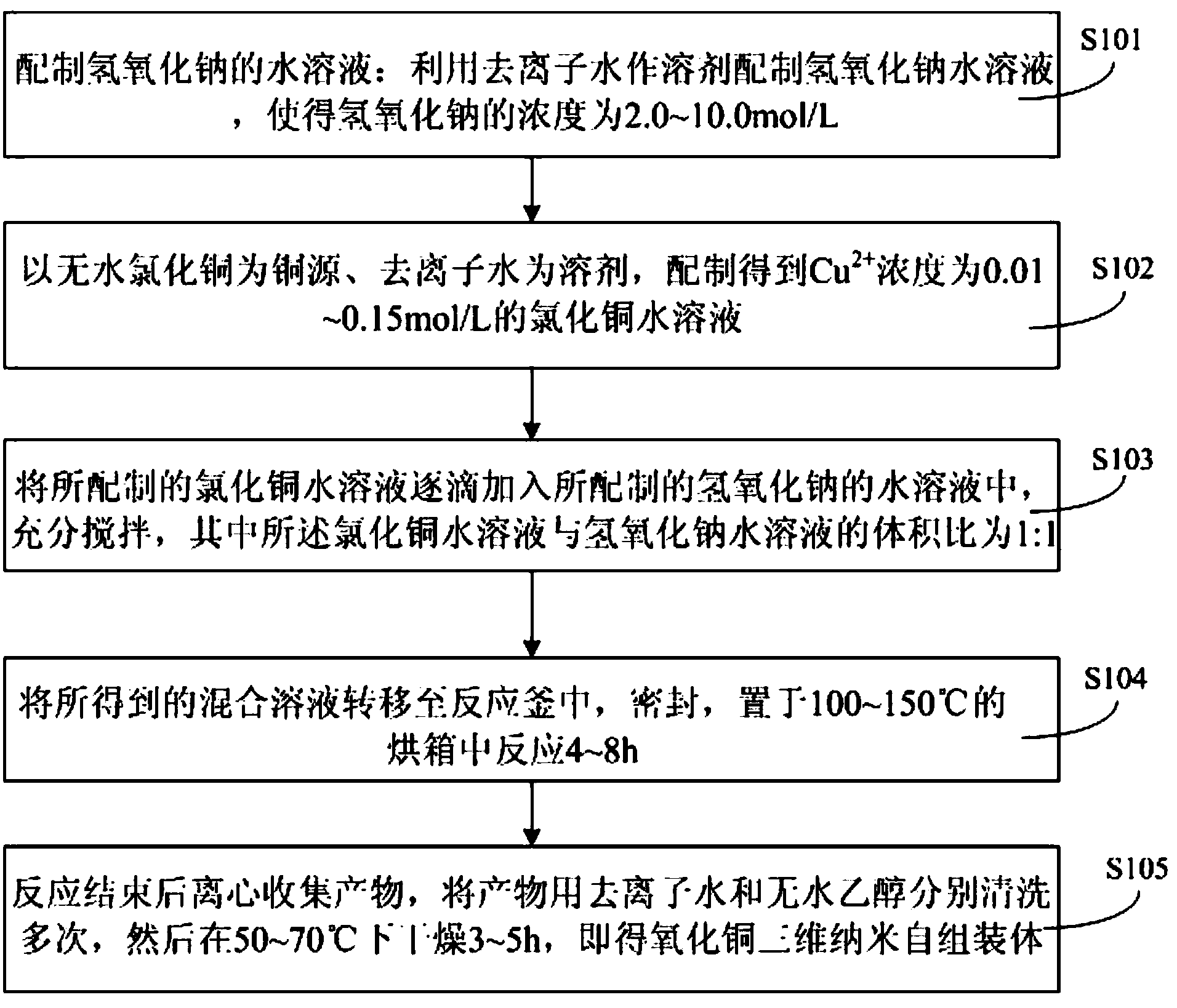

[0027] see figure 1 , shows a flow chart of the steps of the method for the controllable preparation of copper oxide three-dimensional nano self-assembled body according to the embodiment of the present invention, which includes the following steps:

[0028] S101, preparing an aqueous solution of sodium hydroxide: using deionized water as a solvent to prepare an aqueous solution of sodium hydroxide so that the concentration of sodium hydroxide is 2.0-10.0 mol / L;

[0029] S102, using anhydrous copper chloride as copper source and deionized water as solvent, prepared Cu 2+ Copper chloride aqueous solution with a concentration of 0.01-0.15mol / L;

[0030] S103, adding the prepared aqueous copper chloride solution dropwise into the prepared aqueous sodium hydroxide solution, and fully stirring, wherein the volume ratio of the aqueous copper chloride solution to the aqueous sodium hydroxide solution is 1:1;

[0031] S104, transferring the obtained mixed solution into a reaction ke...

Embodiment 1

[0038] A method for the controllable preparation of copper oxide three-dimensional nanometer self-assembly, comprising the following steps:

[0039] Step 1: prepare 11.25 mL of sodium hydroxide aqueous solution: use deionized water as solvent to prepare sodium hydroxide aqueous solution, so that the concentration of sodium hydroxide is 8.0mol / L;

[0040] Step 2: Take anhydrous copper chloride as the copper source and deionized water as the solvent to prepare Cu 2+ 11.25 mL of a solution with a concentration of 0.01 mol / L;

[0041] Step 3: adding the copper chloride aqueous solution dropwise into the sodium hydroxide aqueous solution, and fully stirring;

[0042] Step 4: Transfer the solution obtained in step 3 to a 30mL reactor so that the total volume of the reaction solution accounts for 75% of the volume of the reactor, seal it, and place it in an oven at 120°C for 6 hours;

[0043] Step 5: After the reaction, the product was collected by centrifugation, washed with deion...

Embodiment 2

[0045] A method for the controllable preparation of copper oxide three-dimensional nanometer self-assembly, comprising the following steps:

[0046] Step 1: prepare 106.25 mL of sodium hydroxide aqueous solution: use deionized water as solvent to prepare sodium hydroxide aqueous solution, so that the concentration of sodium hydroxide is 4.0mol / L;

[0047] Step 2: Take anhydrous copper chloride as the copper source and deionized water as the solvent to prepare Cu 2+ 106.25 mL of a solution with a concentration of 0.10 mol / L;

[0048] Step 3: adding the copper chloride aqueous solution dropwise into the sodium hydroxide aqueous solution, and fully stirring;

[0049] Step 4: Transfer the solution obtained in step 3 to a 250mL reactor so that the total volume of the reaction solution accounts for 85% of the volume of the reactor, seal it, and place it in an oven at 150°C for 8 hours;

[0050] Step 5: After the reaction, the product was collected by centrifugation, washed with de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com