La0.1Bi0.9FeO3/BiY2Fe5O12 magnetoelectric composite powder and preparation method thereof

A biy2fe5o12, magnetoelectric composite technology, applied in the field of material science, can solve the problems of poor uniformity of the final composite powder, affecting the performance of the final composite powder, and high calcination temperature, so as to overcome the high synthesis temperature, save energy, and prepare low temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

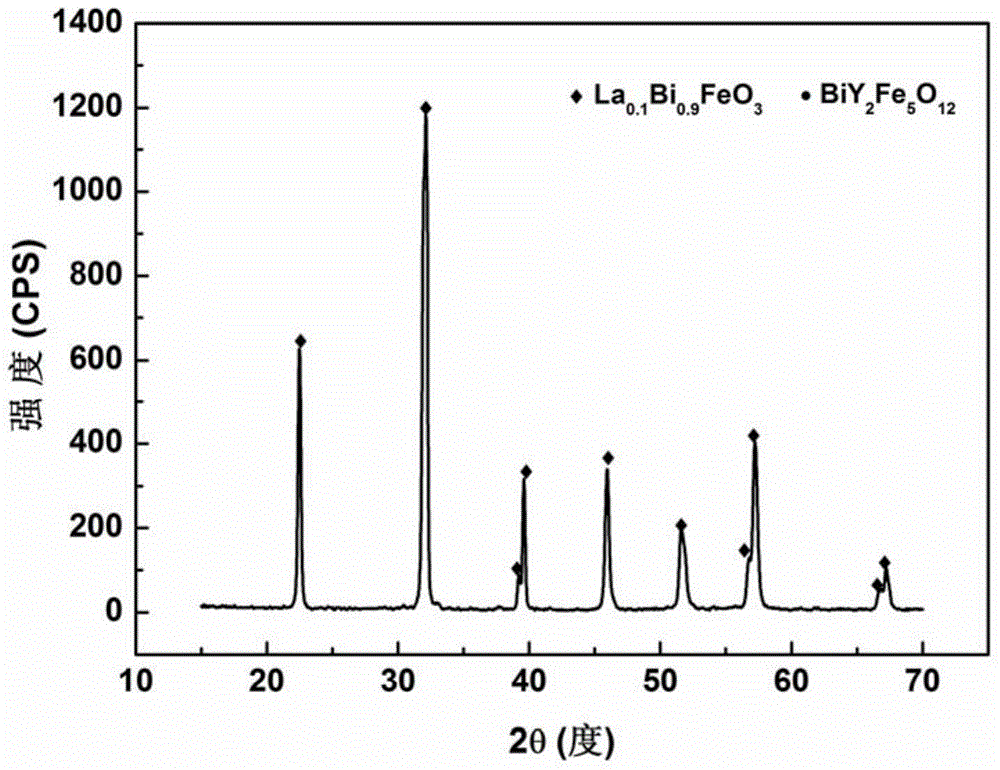

Embodiment 1

[0036] 1) According to the general chemical formula xLa 0.1 Bi 0.9 FeO 3 / (1-x)BiY 2 Fe 5 o 12 , will analyze pure Fe(NO 3 ) 3 9H 2 O, Bi(NO 3 ) 3 9H 2 O, La(NO 3 ) 3 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 O was added to distilled water to prepare a solution; where, x was La 0.1 Bi 0.9 FeO 3 The mass percentage of , and x=0.9;

[0037] 2) Add citric acid to the solution in step 1), and stir for 1 hour under heating in a water bath at 80°C to obtain sol A. 2 times the total molar mass of ions;

[0038] 3) Under stirring, use ethylenediamine to adjust the pH value of sol A to 6.5 to obtain uniform sol B;

[0039] 4) Put sol B into a vacuum drying oven and dry at 200°C for 2 hours to obtain a dark brown loose xerogel;

[0040] 5) Grind the dry gel and put it into a crucible, and place the crucible in an electric furnace for calcination at 800°C for 1 hour to obtain La 0.1 Bi 0.9 FeO 3 / BiY 2 Fe 5 o 12 Magnetoelectric composite powder.

[0041] The La prepared ...

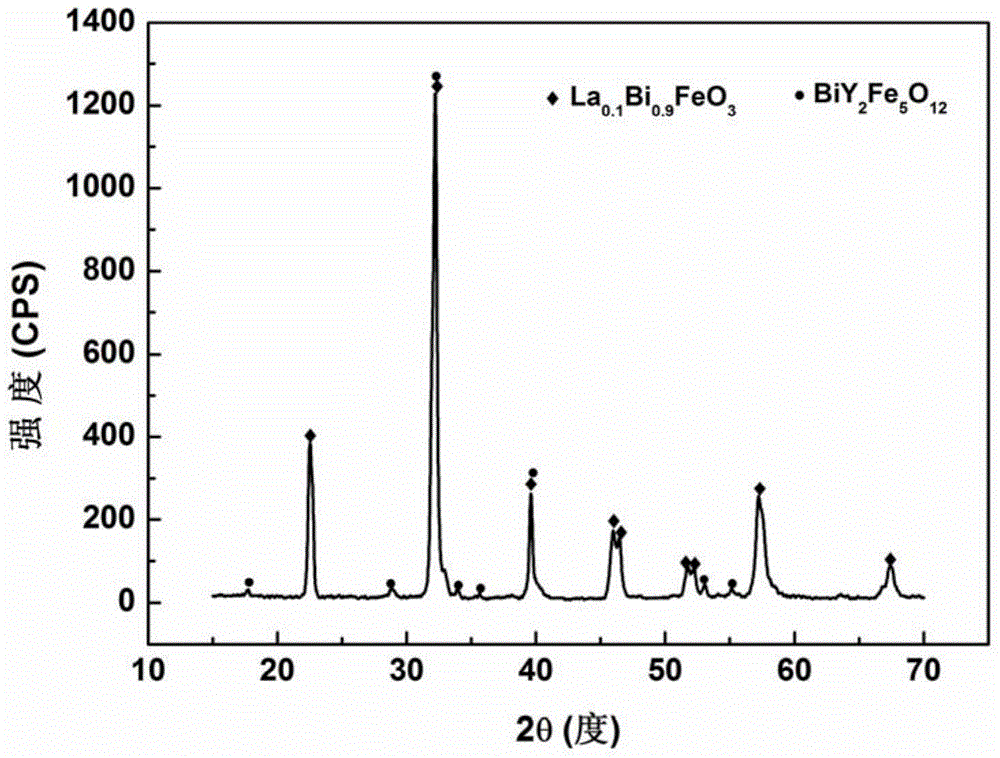

Embodiment 2

[0046] 1) According to the general chemical formula xLa 0.1 Bi 0.9 FeO 3 / (1-x)BiY 2 Fe 5 o 12 , will analyze pure Fe(NO 3 ) 3 9H 2 O, Bi(NO 3 ) 3 9H 2 O, La(NO 3 ) 3 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 O was added to distilled water to prepare a solution; where, x was La 0.1 Bi 0.9 FeO 3 The mass percentage of , and x=0.8;

[0047] 2) Add citric acid to the solution in step 1), and stir for 1 hour under heating in a water bath at 100°C to obtain sol A, wherein the molar amount of citric acid added is the four metals in the solution: iron ion, bismuth ion, lanthanum ion, and yttrium ion 3 times the total molar mass of ions;

[0048] 3) Under stirring, use ethylenediamine to adjust the pH value of Sol A to 7.5 to obtain uniform Sol B;

[0049] 4) Put Sol B into a vacuum drying oven and dry at 190°C for 3 hours to obtain a dark brown loose xerogel;

[0050] 5) Put the dry gel into a crucible after grinding, and place the crucible in an electric furnace for calcin...

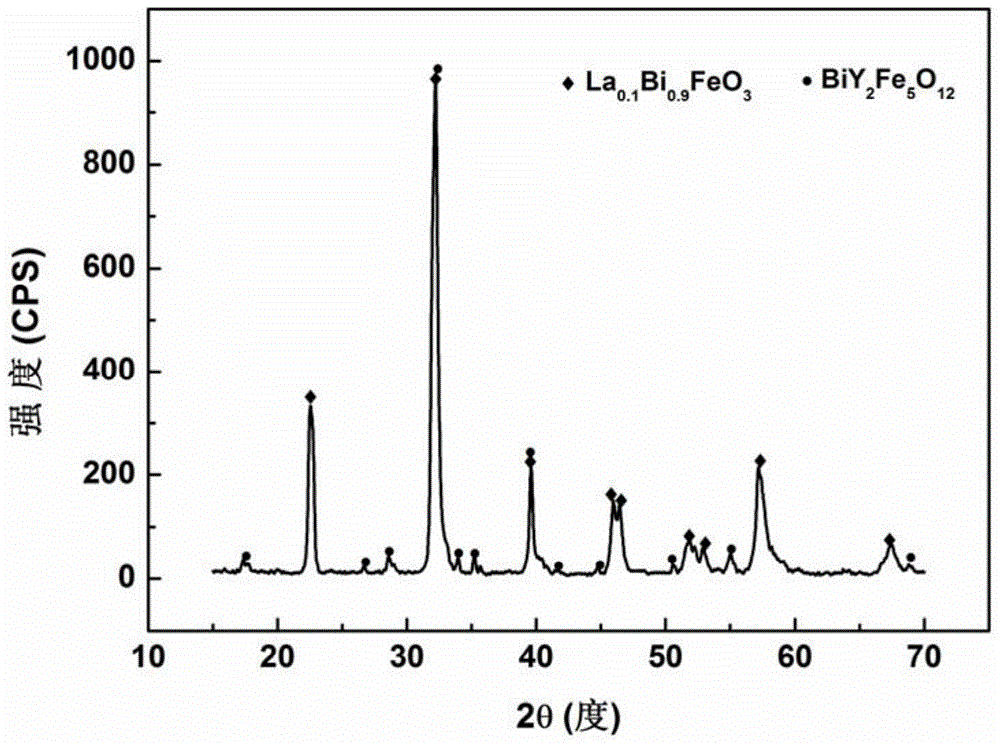

Embodiment 3

[0056] 1) According to the general chemical formula xLa 0.1 Bi 0.9 FeO 3 / (1-x)BiY 2 Fe 5 o 12 , will analyze pure Fe(NO 3 ) 3 9H 2 O, Bi(NO 3 ) 3 9H 2 O, La(NO 3 ) 3 ·6H 2 O and Y (NO 3 ) 3 ·6H 2 O was added to distilled water to prepare a solution; where, x was La 0.1 Bi 0.9 FeO 3 The mass percentage of , and x=0.7;

[0057] 2) Add citric acid to the solution in step 1), and stir for 2 hours under heating in a water bath at 90°C to obtain Sol A, wherein the molar amount of citric acid added is the four metals in the solution: iron ion, bismuth ion, lanthanum ion, and yttrium ion 4 times the total molar mass of ions;

[0058] 3) Under stirring, use ethylenediamine to adjust the pH value of sol A to 7 to obtain uniform sol B;

[0059] 4) Put Sol B into a vacuum drying oven and dry at 180°C for 4 hours to obtain a dark brown loose xerogel;

[0060] 5) Put the dry gel into a crucible after being ground, and place the crucible in an electric furnace for calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com