Preparation method of thermosensitive sensitizer

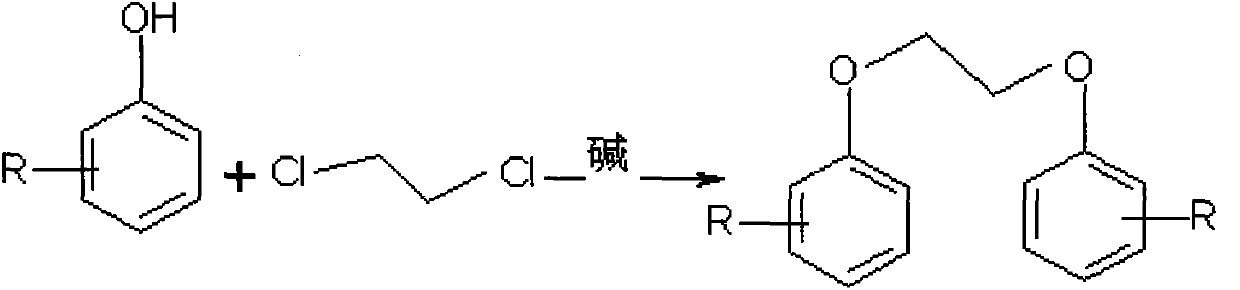

A kind of sensitizer, dichloroethane technology, applied in ether preparation, ester reaction preparation ether, coating and other directions, can solve the problems of difficult handling, low yield, etc., achieve mild reaction conditions, high yield, raw materials easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

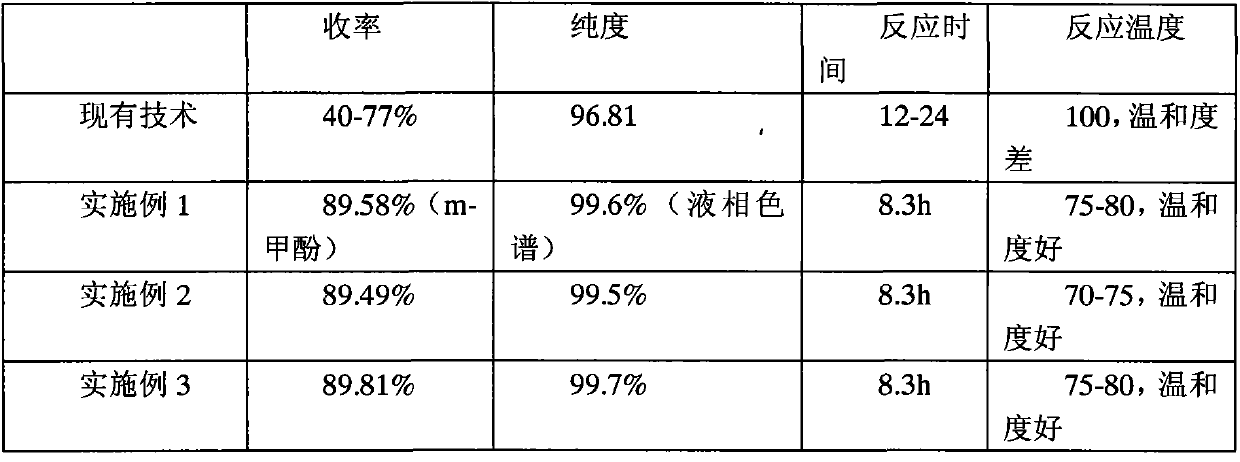

[0014] A kind of preparation method of thermosensitive sensitizer, it is characterized in that, 89.1g (0.9 mole) dichloroethane and 200g (1.85 mole) m-cresol and 35ml water are added in the kettle, under the situation of nitrogen protection Stir, add dropwise 49% (weight standard) sodium hydroxide aqueous solution 100g when using 20 minutes, dropwise add 49% sodium hydroxide aqueous solution 72g with 2 hours after dropwise heating reflux 3 hours, then transfer solution to separation Drain the water layer, transfer the oil layer back to the reactor to continue the condensation reaction at 75-80°C for 3 hours, divide the outflow of 95ml of water, then add 175ml of water and heat to 100°C, stir, stand still, and separate layers to obtain 204.7g1,2 - Crude organic layer of bis(3-methylphenoxy)ethane (HPLC detection: 96.5%, yield 93.98%), the crude product was purified by rectification to obtain 195.1g of 1,2-bis(3-methylphenoxy base) ethane (HPLC detection: purity 99.6%, yield 89....

Embodiment 2

[0016] A kind of preparation method of thermosensitive sensitizer, it is characterized in that, 89.1g (0.9 mole) dichloroethane and 200g (1.85 mole) o-cresol and 35ml water are added in the kettle, carry out under the situation that there is nitrogen protection Stir, add dropwise 49% (weight standard) sodium hydroxide aqueous solution 100g when using 20 minutes, dropwise add 49% sodium hydroxide aqueous solution 72g with 2 hours after dropwise heating reflux after 3 hours, then solution is transferred to separator , drain the water layer, turn the oil layer back into the reactor to continue the condensation reaction at 70-75°C for 3 hours, divide the outflow of 95ml of water, then add 175ml of water and heat to 100°C, stir, stand still, and separate layers to obtain 203.9g of 1,2- Bis(3-methylphenoxy)ethane organic layer crude product (HPLC: 96.8%, yield 93.62%), the crude product was purified by rectification to obtain 194.9g of 1,2-bis(2-methylphenoxy) Ethane (HPLC detection...

Embodiment 3

[0018] A kind of preparation method of thermosensitive sensitizer, it is characterized in that, 89.1g (0.9 mole) dichloroethane and 200g (1.85 mole) p-cresol and 35ml water are added in the still, carry out under the situation that there is nitrogen protection Stir, add dropwise 49% (weight standard) sodium hydroxide aqueous solution 100g when using 20 minutes, dropwise add 49% sodium hydroxide aqueous solution 72g with 2 hours after dropwise heating reflux after 3 hours, then solution is transferred to separator , drain the water layer, turn the oil layer back into the reactor to continue the condensation reaction at 75-80°C for 3 hours, divide the outflow of 95ml of water, then add 175ml of water and heat to 100°C, stir, stand still, and separate layers to obtain 205.0g of 1,2- Bis(3-methylphenoxy)ethane organic layer crude product (HPLC: 96.8%, yield 94.12%), the crude product was purified by rectification to obtain 195.6g of 1,2-bis(4-methylphenoxy) Ethane (HPLC detection:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com