Method for preparing 2,2'-(4,4'-distyryl)bisbenzoxazole fine product

A distyryl and benzoxazole technology, which is applied in the field of chemical raw material preparation, can solve problems such as low content and purity, high reaction temperature, and operator injury, and achieve high purity and yield, good product quality, and safety The effect of high coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 A kind of method for preparing 2,2'-(4,4'-distyryl) bisbenzoxazole fine product

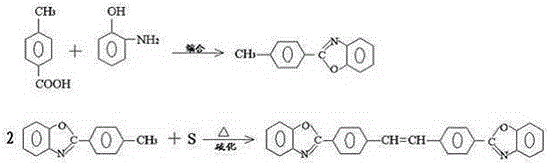

[0030] A method for preparing 2,2'-(4,4'-distyryl)bisbenzoxazole refined product, which is realized through condensation reaction, vulcanization reaction, crude product, and solid-liquid separation. The reaction equation is as follows:

[0031]

[0032] The specific preparation method is carried out according to the following steps:

[0033] ⑴Condensation reaction

[0034] Mix p-toluic acid and o-aminophenol with a weight ratio of 136:109 in the condensation reaction kettle, add xylene solvent, and react to generate 2-(p-methylbenzene)benzoxazole, at 200°C, vacuum state, distill 2-(p-methylbenzene)benzoxazole to obtain A;

[0035] ⑵Vulcanization reaction

[0036] Put A into a vulcanization reaction kettle, put in sulfur 1.0 times the weight of A, raise the temperature to 210°C, react for 16 hours, add xylene solvent, heat the solution to 130°C, keep it warm for 2 hours, ...

Embodiment 2-6

[0042] Embodiment 2-6 prepares the method for 2,2'-(4,4'-distyryl) bisbenzoxazole fine product

[0043] Examples 2-6 are respectively a method for preparing 2,2'-(4,4'-distyryl)bisbenzoxazole refined products. The preparation process is the same as that of Example 1, except that the The parameters involved are different, as shown in Table 1:

[0044] Table 1 prepares 2,2'-(4,4'-distyryl) the relevant parameters involved in the method of bisbenzoxazole fine work

[0045]

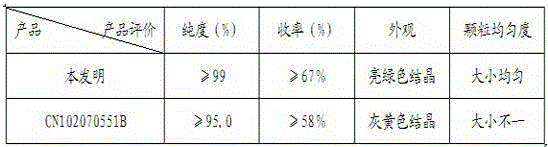

[0046]It can be seen from Table 1 that the product OB-1 prepared in Example 2-6 has a purity of ≥99%, a yield of ≥92.5%, good product quality, bright green or bright yellow-green appearance, bright color, no impurities, and uniform crystal size and texture , The temperature is not required to be too high during refining and filtration, and the process of washing with xylene is omitted, the solvent consumption is low, the safety factor of the production process is high, the operation is safe, and the cost ...

Embodiment 7

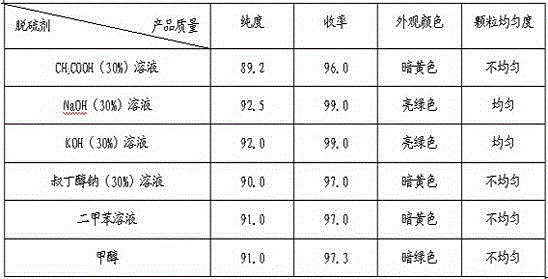

[0047] The influence of different desulfurization detergents of embodiment 7 on product OB-1

[0048] The residual sulfur in the product OB-1 will reduce the yield and purity of the product, resulting in poor product quality, dark color, and product particle crystals of different sizes. Therefore, it is necessary to wash off the residual sulfur with different desulfurization detergents. It is of great significance to improve the quality of product OB-1 and reduce the production cost.

[0049] Different desulfurization detergents in the refining process have different effects on the removal of residual sulfur in the product OB-1. In Example 7, the impact of different detergents on the product OB-1 was explored. The preparation process of the product OB-1 was compared with Embodiment 1 is the same, and the difference is only that the desulfurization detergent added in the crude product refining process is different, specifically as shown in Table 2:

[0050] Table 2 Effect of d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com