Method for efficiently extracting polysaccharide active ingredients in lycium barbarum by using ultrasound enhanced subcritical water

A Lycium barbarum polysaccharide and subcritical water technology, applied in the field of plant polysaccharide extraction, can solve the problems of easy damage to the molecular structure of polysaccharides, unsuitability for industrial production, and high production costs, and achieve simple pre-treatment of materials, natural and pollution-free solvent sources, The effect of improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

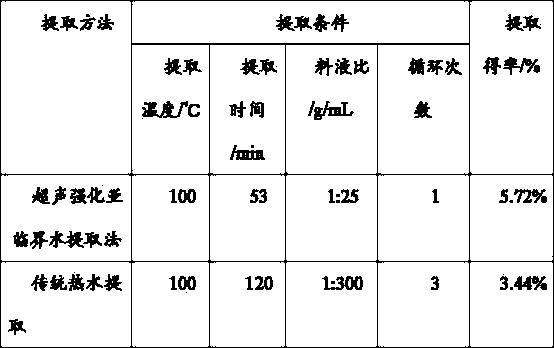

Embodiment 1

[0025] Ultrasonic-enhanced subcritical water extraction method: Put the wolfberry fruit dried to constant weight directly into the extraction tank without crushing; use a pump to extract preheated deionized water according to the volume-to-mass ratio of liquid to material 30:1 (mL / g ) into the extraction tank at a flow rate of about 70mL / min; control the temperature in the extraction tank to 110°C and the pressure to 5MPa. In this extraction stage, introduce ultrasonic waves into the extraction tank, control the ultrasonic frequency to 18.5Hz, and the ultrasonic power to 160W , extracted for 80min, the crude polysaccharide yield of Lycium barbarum was 14.12%, and the extraction yield was 5.569%.

Embodiment 2

[0027] Ultrasound-enhanced subcritical water extraction method: the experimental treatment process is the same as in Example 1, the difference is that the liquid-to-solid ratio is 20:1, the ultrasonic power is 140W, the yield of the crude polysaccharide from Lycium barbarum is 13.87%, and the extraction yield is 5.345%.

Embodiment 3

[0029] Ultrasonic enhanced subcritical water extraction method: the experimental treatment process is the same as in Example 1, the difference is that the liquid-to-solid ratio is 25:1, and the extraction time is 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com