Alkaline chemical mechanical polishing liquid

A chemical mechanical and polishing liquid technology, which is applied in the fields of polishing compositions containing abrasives, electrical components, semiconductor/solid-state devices, etc., and can solve problems such as excessive edge erosion and unsuitable metal materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The advantages of the present invention are further described below through specific examples, but the protection scope of the present invention is not limited only to the following examples.

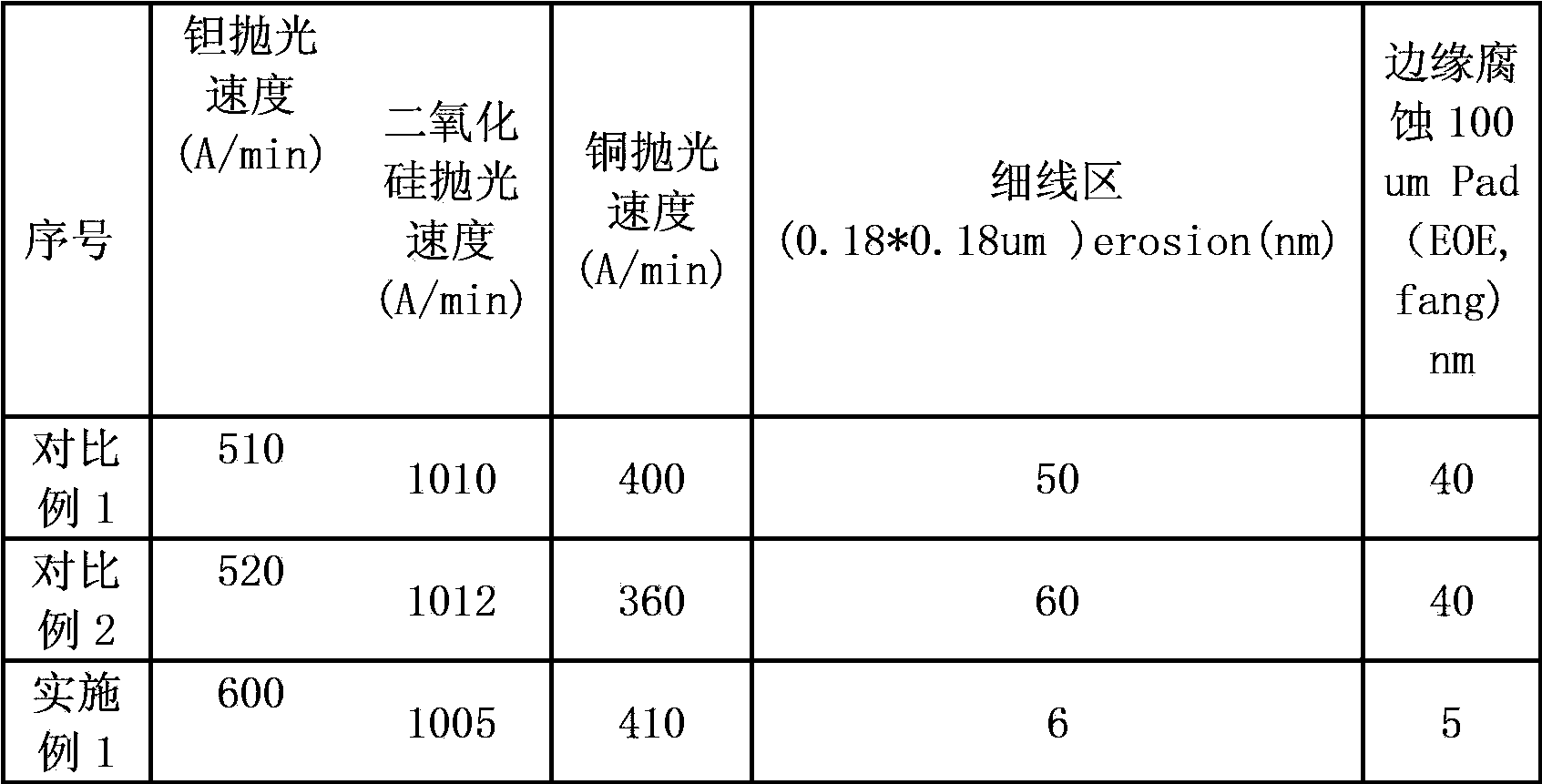

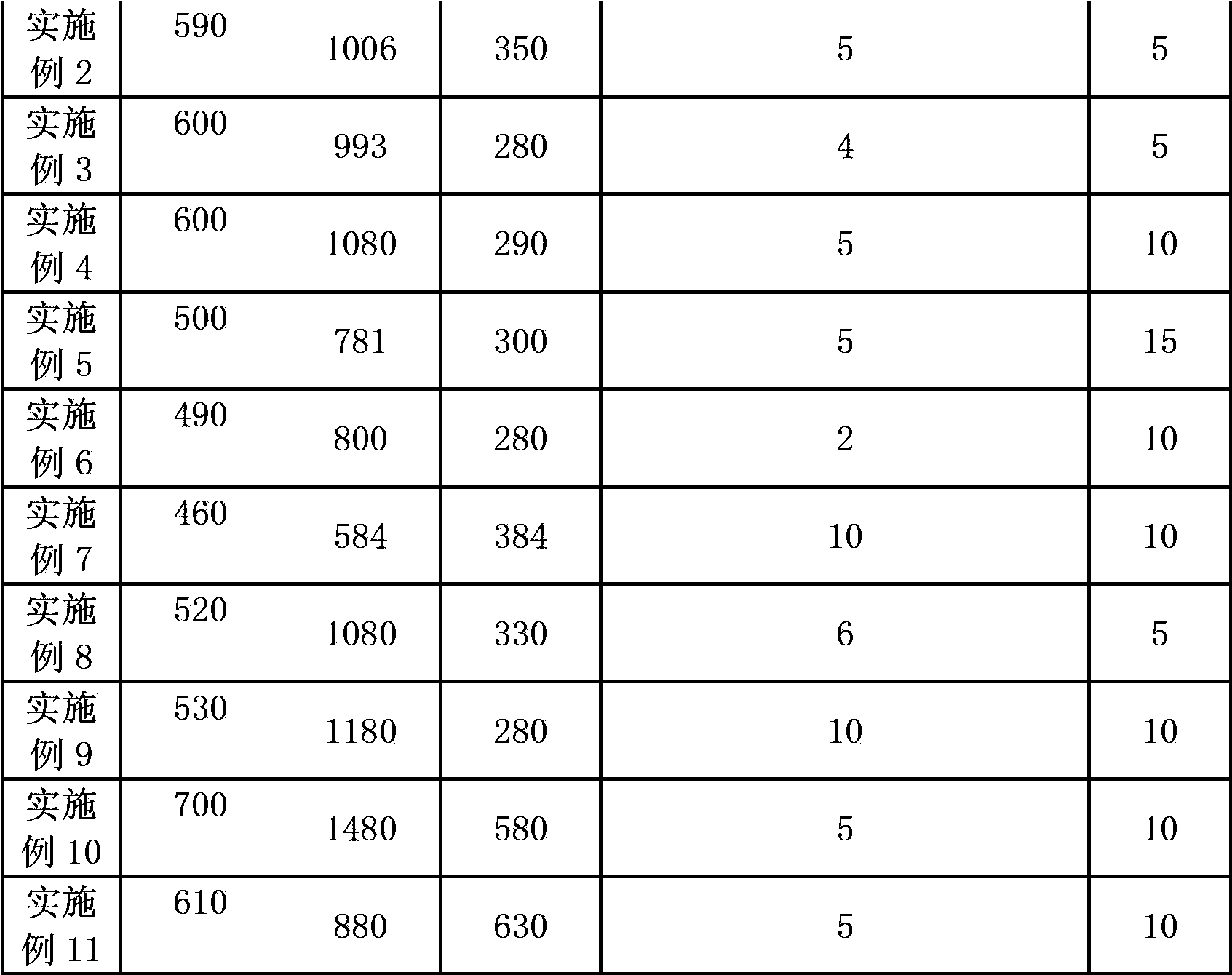

[0034] The polishing liquid was prepared according to the ingredients and proportions of each embodiment in Table 1, and mixed evenly.

[0035] The formula of table 1 embodiment 1-11 of the present invention and comparative example 1-2

[0036]

[0037] Among them, IRGAMET42* is a commercially available passivating agent, which is a derivative of TTA, and TTA is tolyltriazole.

[0038] Nonylphenol polyoxyethylene ether is selected from IGEPAL CO850 (Ethoxylated nonylphenol).

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com