Anti-condensation and anti-frosting refrigeration appliance

A refrigeration appliance and anti-frost technology, which is applied to household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve problems such as affecting refrigeration efficiency, and achieve the effect of improving heat exchange efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

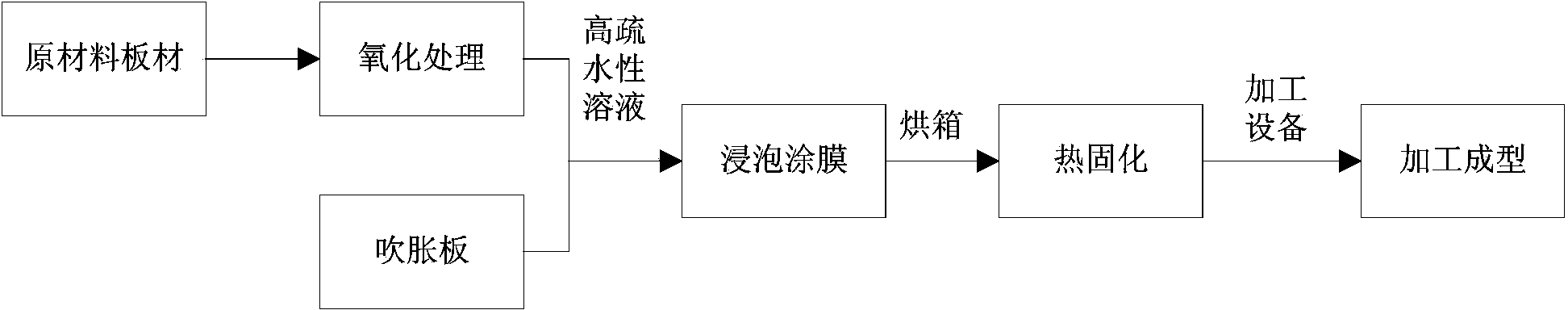

[0033] combine Figures 1 to 2 The specific embodiment of the present invention is described further:

[0034] An anti-condensation and anti-frost refrigeration appliance, the inner tank wall or evaporator of the refrigeration appliance adopts the following preparation steps:

[0035] (1) A dense oxide film is formed on the surface of the raw material plate after oxidation treatment;

[0036] (2) Fully immerse the board and inflation board obtained in step (1) into the coating film in the highly hydrophobic coating solution;

[0037] (3) Dry the board and inflation board obtained in step (2) and put them in an oven for thermal curing;

[0038] (4) Process the plate obtained in step (3) into the inner tank wall of the refrigeration appliance through the processing equipment, and process the inflation plate obtained in the step (3) into the evaporator of the refrigeration appliance through the processing equipment.

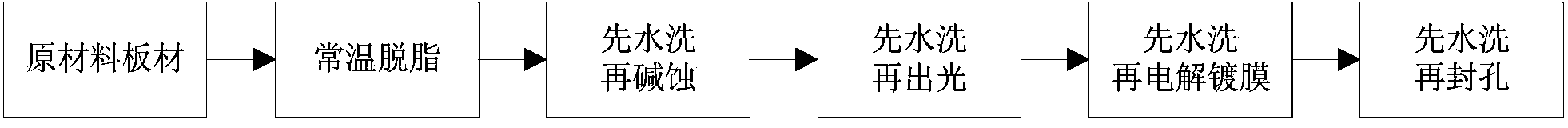

[0039] The steps of oxidation treatment in step (1) are as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com