Electric kiln

A technology of electric kiln and kiln body, applied in the field of electric kiln, can solve the problems of high labor intensity, high manufacturing cost and high production cost of push plate kiln and tunnel kiln, and achieve good product consistency, flexibility and quality Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with accompanying drawing:

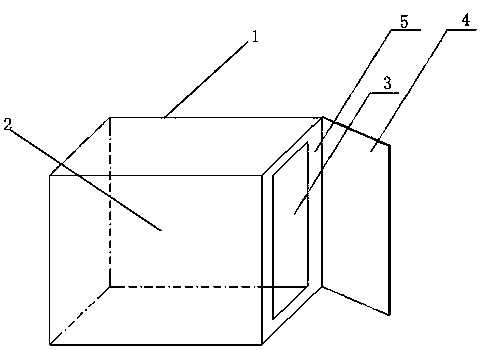

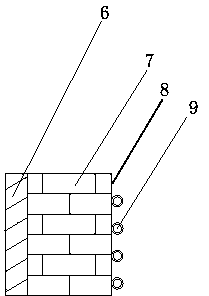

[0024] Such as figure 1 , 2 As shown, an electric kiln according to the present invention comprises a kiln body 1, a kiln chamber 2 and a kiln chamber mouth 3, and a kiln door 4 is arranged on the kiln body 1 on one side of the kiln chamber mouth 3; 1 The kiln wall 5 on each side has a three-layer structure of outer, middle and inner layers, the outer layer is a metal shell 6, the middle layer is a heat insulation layer 7, and the inner layer is a heating layer 8.

[0025] The metal shell 6 mentioned above adopts an iron plate with a thickness of 3 mm and brushed with anti-corrosion and anti-rust paint; the heat insulation layer 7 adopts alumina foam bricks with a thickness of 80 mm; the heating layer 8 is provided with a heating wire 9 .

[0026] Above-mentioned is only the preferred embodiment of the present invention, it should be pointed out that for those of ordinar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com