Laser direct writing exposure device based on stimulated light emission loss

A technology of stimulated emission of light and laser direct writing, which is applied in the field of optical exposure and can solve problems such as unconsidered, enhanced resolution, and high requirements for thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

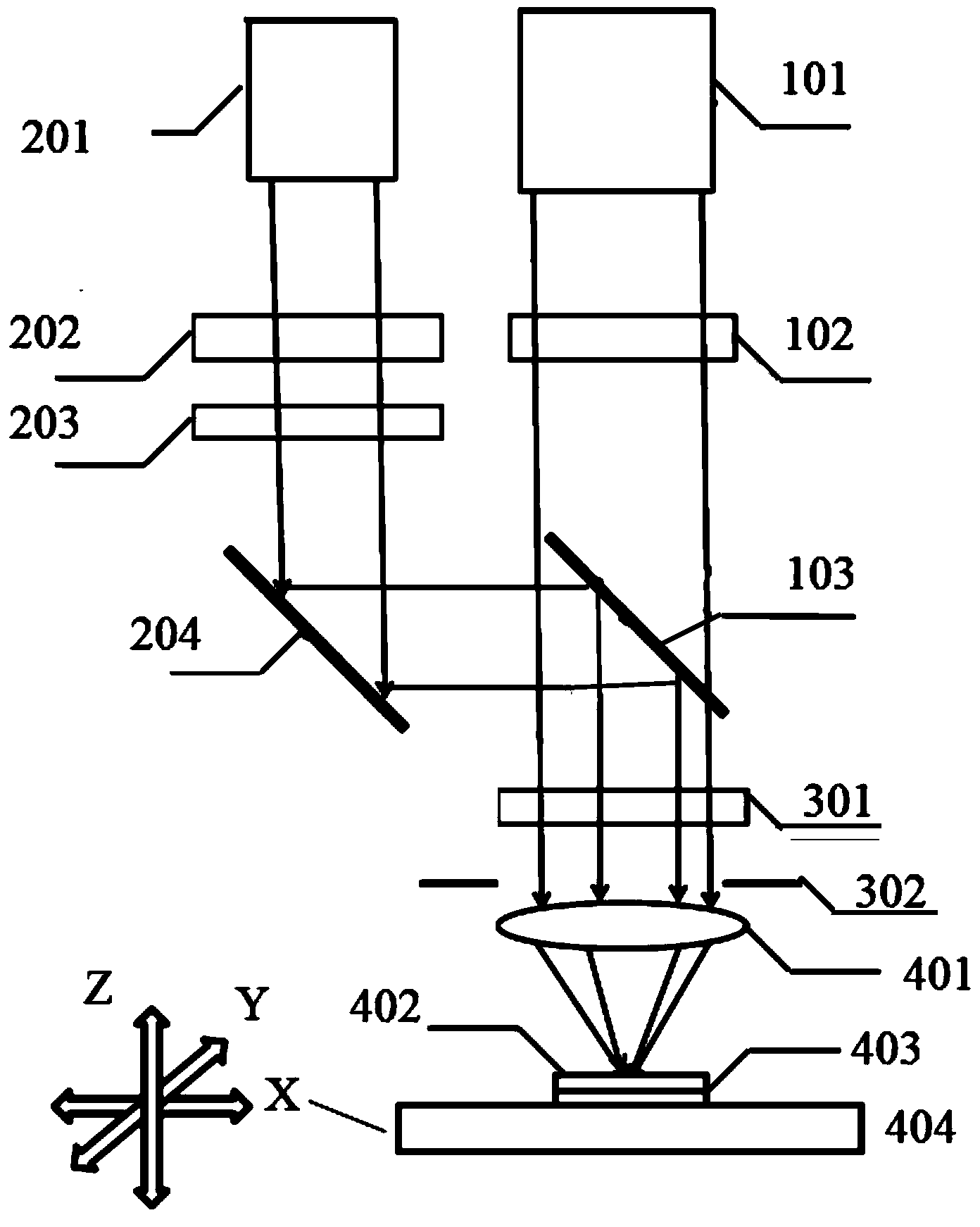

Method used

Image

Examples

specific Embodiment

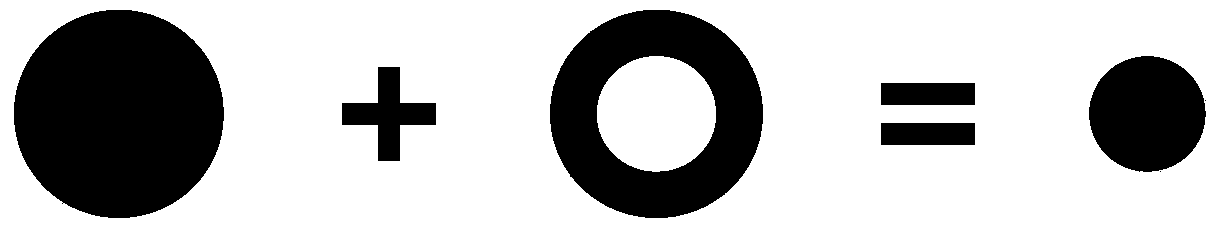

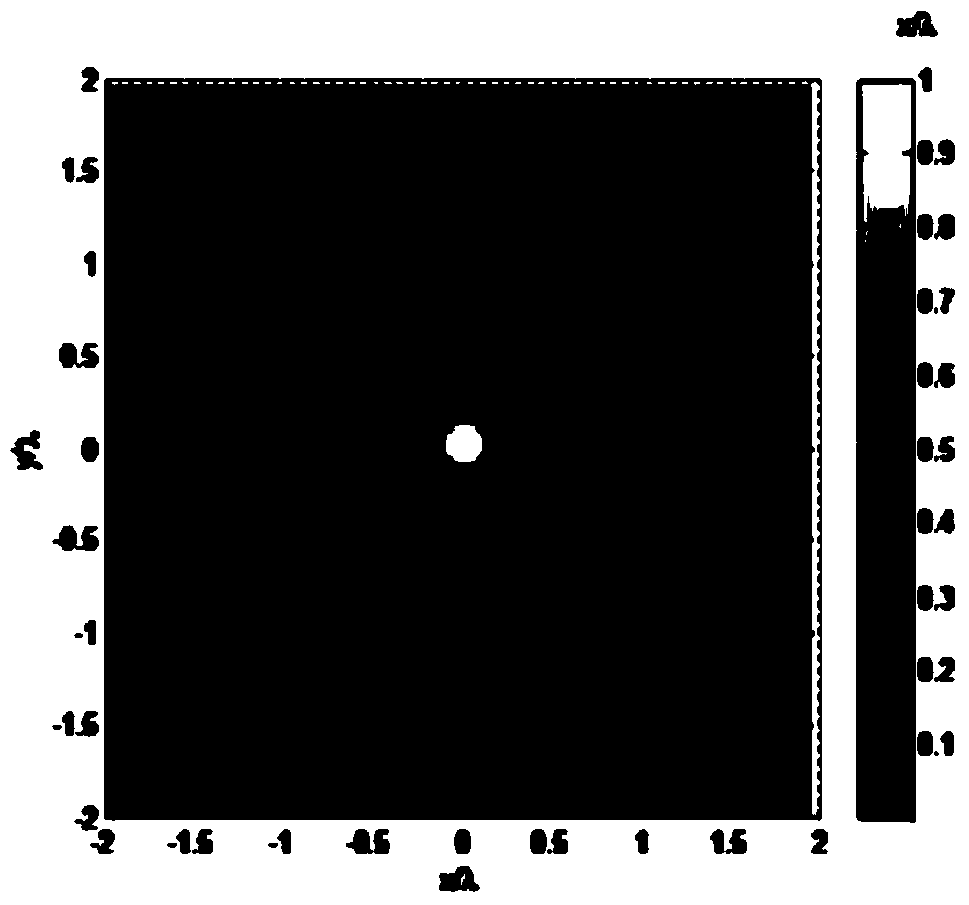

[0076] In this specific embodiment, the numerical aperture NA=0.95 of selecting high numerical aperture achromatic objective lens 401; The phase control parameter σ=30 of phase type zone plate 301 -5 , f=12; beam relative size δ 0 =1.2; the radius ratio of the amplitude-type zone plate 302 is η=0.92, and η is the ratio of the radius of the central light-transmitting region of the amplitude-type zone plate to the radius of the outer circle; the absorption factor ξ=100. The obtained light field on the focal plane is shown in Figure 3, where Figure 3a is the light field distribution formed by the excitation light source on the focal plane, and the coordinate axis in the figure is in wavelength. said Figure 3b is the light field distribution of the de-excitation light on the focal plane, and the center of the field of the de-excitation light on the focal plane is a dark field. Therefore, the ring-shaped area of the photoresist irradiated by the de-excitation light cannot co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com