Parallel laser direct writing system and photoetching method

A laser direct writing and optical system technology, applied in the fields of mask preparation, maskless lithography, and laser direct writing, can solve the problems of high-magnification miniaturization technology difficulty, low writing efficiency, uneven line width, etc., and achieve anti-aliasing. phenomenon, improved line width uniformity, accuracy and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

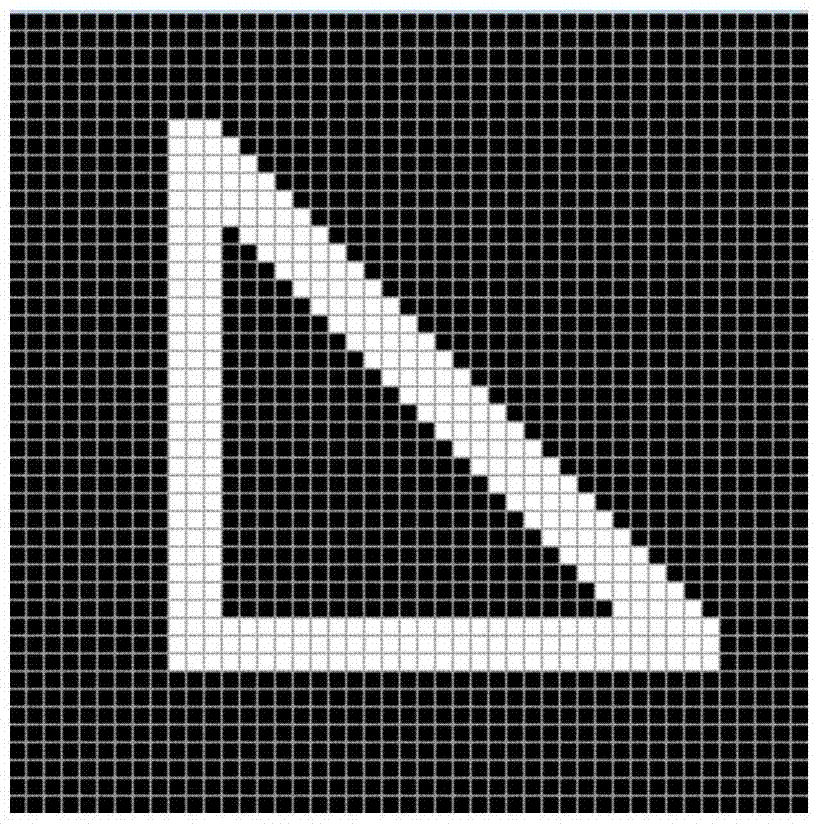

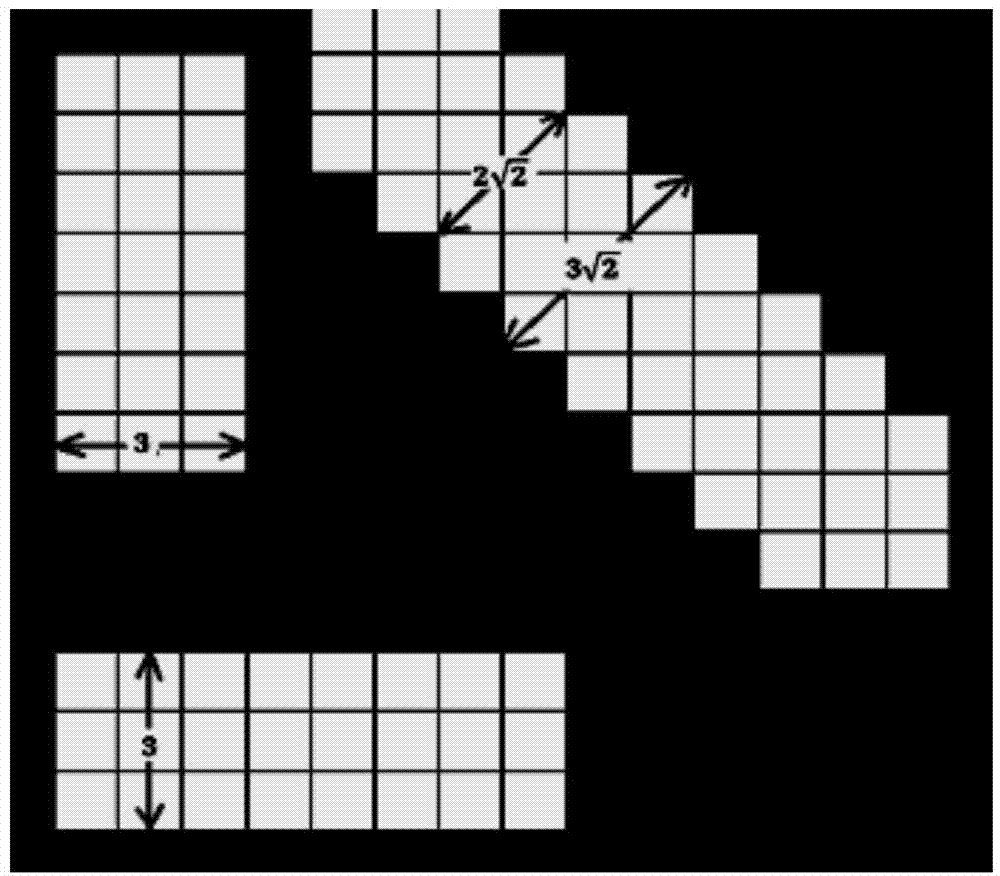

[0040] As mentioned in the background technology, the existing parallel laser direct writing system, due to the spatial light modulator as a pattern generator, has a jagged problem when displaying oblique lines, resulting in uneven lines in all oblique lines obtained by exposure At the same time, the line widths of oblique lines and straight lines are not equal, so that the graphics obtained by the exposure of the entire system cannot obtain uniform line width values.

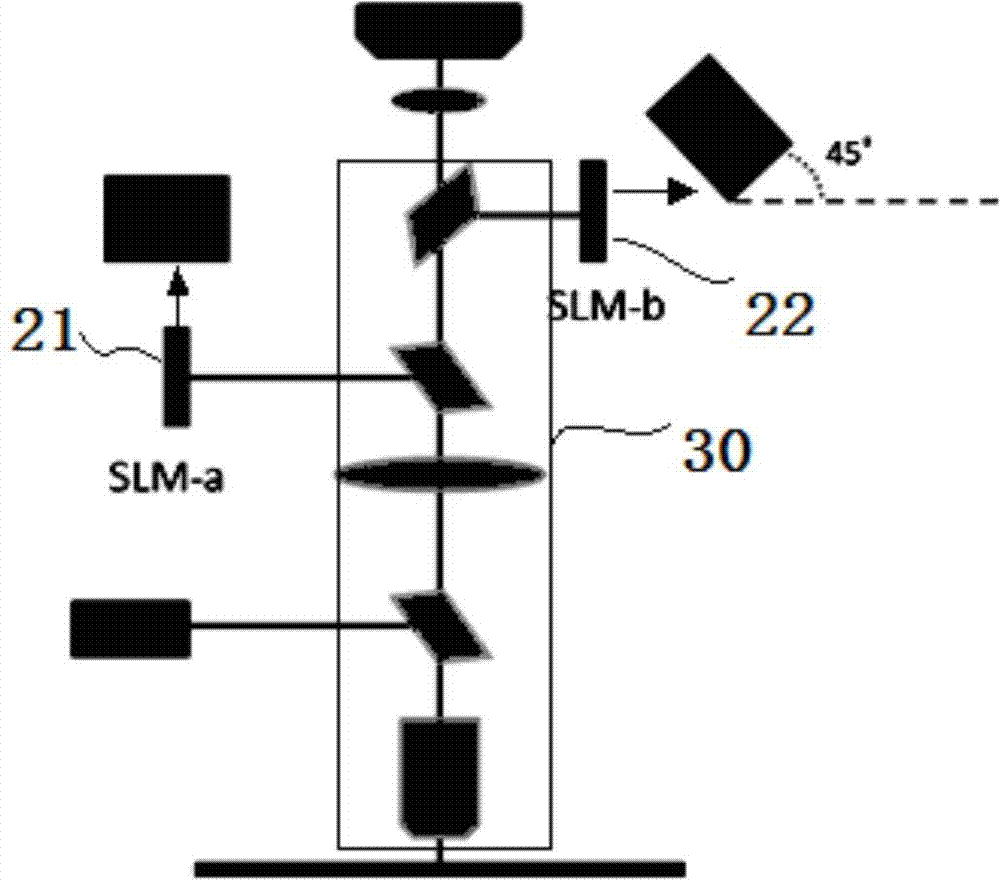

[0041] Therefore, the present invention designs a new parallel laser direct writing system aiming at the problems existing in the prior art. The parallel laser direct writing system uses two or more spatial light modulators, and different spatial light modulators are set at different angles. One of the spatial light modulators is used as a standard display, and the displayed graphics are horizontal The direction of the straight line where the pixels are located is the standard horizontal direction, and the dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com