Anti-virus aluminum member and method for producing same

A technology for anti-virus and components, applied in the direction of anti-virus agent, disinfection, coating, etc., to achieve the effect of maintaining excellent anti-virus and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

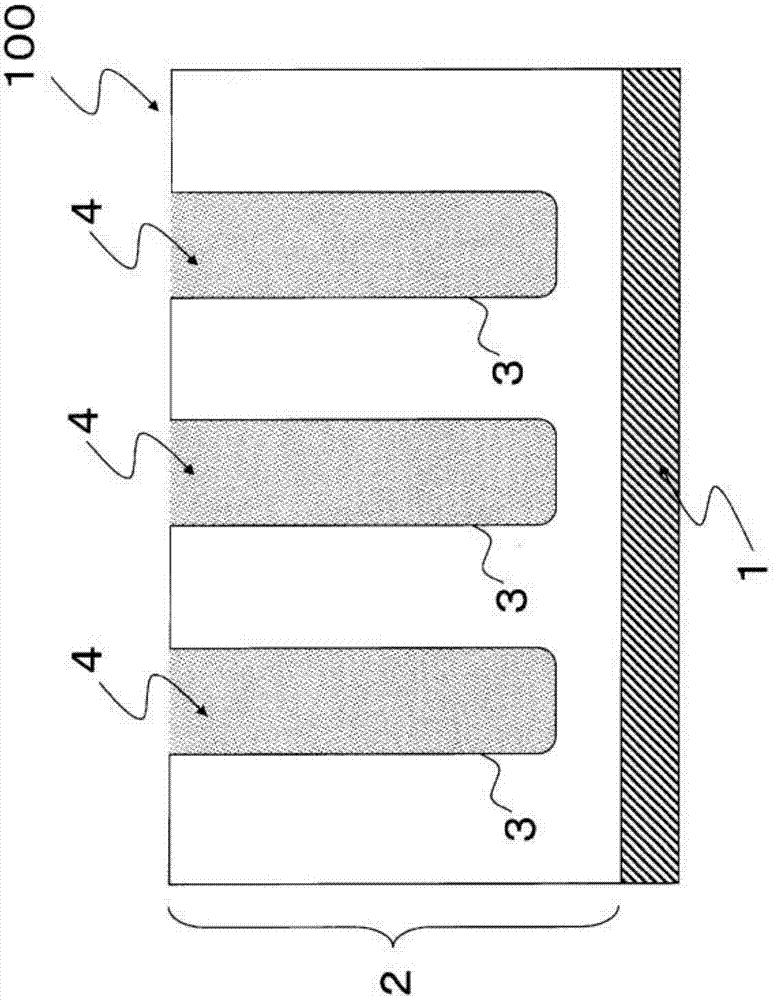

[0043] figure 1 It is an enlarged schematic diagram of a part of the cross section of the antiviral aluminum member 100 according to the first embodiment of the present invention. The aluminum component 100 forms an anodic oxide film 2 on the surface portion of the aluminum component 100 by anodizing aluminum or aluminum alloy. The anodized film 2 is so-called porous alumina, and a large number of micropores 3 having openings are formed on the surface. The metal layer 1 of raw aluminum or raw aluminum alloy that is not anodized is located on the side close to the bottom of the micropore 3 (the side opposite to the surface of the aluminum member 100 having the opening). In this embodiment of the present invention, as figure 1 As shown, a deposit 4 containing an antiviral inorganic compound is deposited in the micropores 3 of the anodic oxide film 2 and fills the micropores 3. For ease of understanding, figure 1 A view showing that the micropore 3 is completely filled with the d...

no. 2 Embodiment approach )

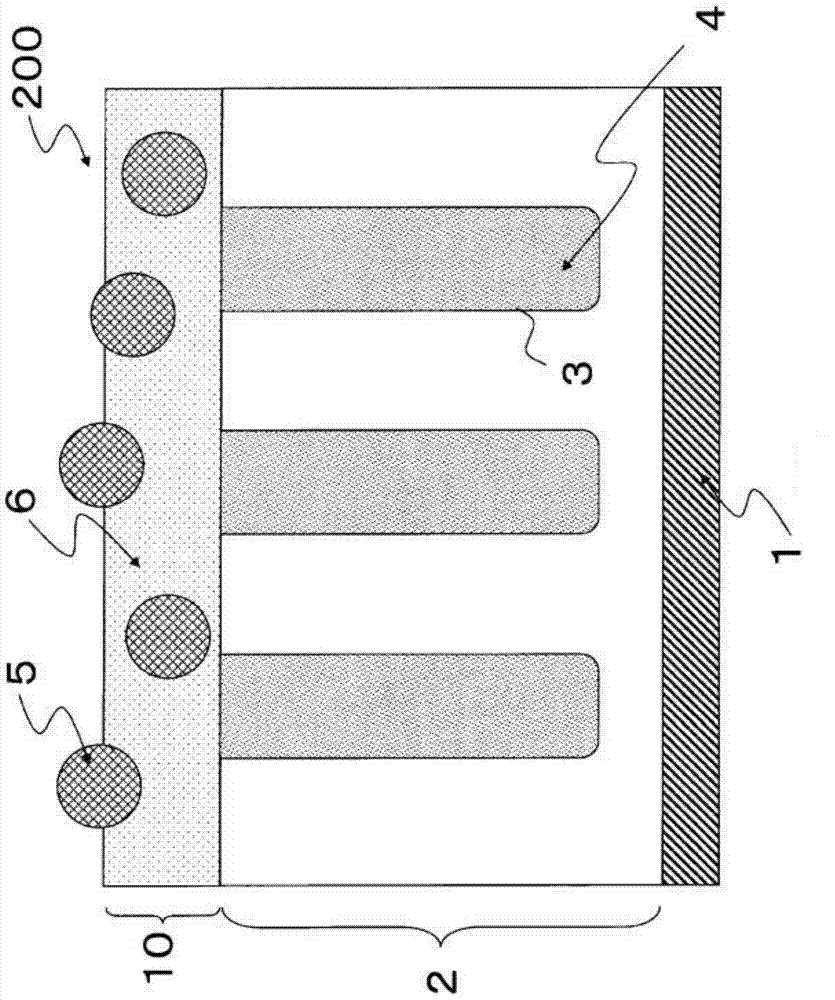

[0055] Next, refer to figure 2 The antiviral aluminum member 200 according to the second embodiment of the present invention will be described in detail.

[0056] figure 2 It is an enlarged schematic diagram of a part of the cross section of the antiviral aluminum member 200 according to the second embodiment of the present invention. As in the first embodiment, on the surface of the metal layer 1 of aluminum or aluminum alloy, an anodic oxide film 2 with micropores 3 formed by anodic oxidation is formed, and a deposit 4 containing an antiviral inorganic compound is deposited and filled in Micropore 3. Furthermore, a surface film 10 composed of inorganic fine particles 5 and a resin binder 6 composed of an antiviral inorganic compound is formed on the surface of the anodic oxide film 2.

[0057] As the resin adhesive 6, a known adhesive can be used. Specific examples of resin binders may include: polyester resin, amino resin, epoxy resin, polyurethane resin, acrylic resin, wate...

no. 3 Embodiment approach )

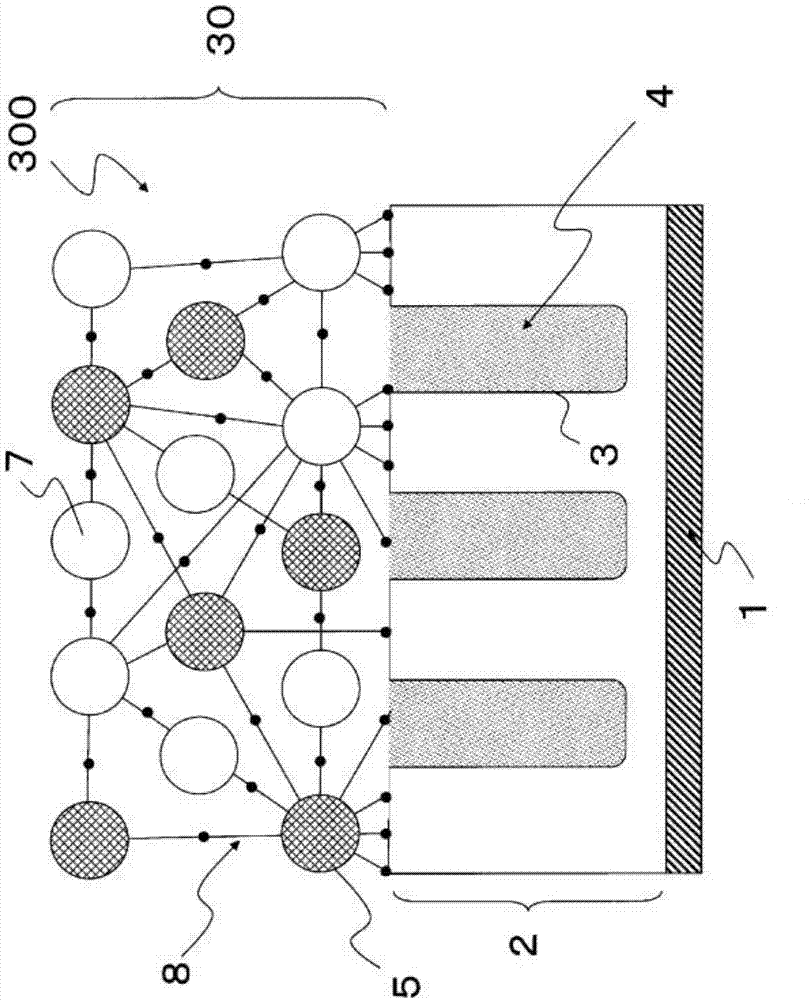

[0068] Next, refer to image 3 The antiviral aluminum member 300 according to the third embodiment of the present invention will be described in detail.

[0069] image 3 It is an enlarged schematic diagram of a part of the cross section of the antiviral aluminum member 300 according to the third embodiment of the present invention. In the third embodiment, a surface film 30 is formed on the surface of the anodic oxide film 2 having micropores 3. The micropores 3 are deposited and filled with a deposit 4 containing an antiviral inorganic compound. The anodic oxide film is similar to the first embodiment. The same way. The surface film 30 contains inorganic particles 5 composed of an antiviral inorganic compound, functional particles 7 for imparting functions other than antiviral properties, and a binder 8 composed of a silane compound. In a specific use environment, for example, a well-known hard coating agent can be added to further improve the strength of the surface film 30. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com