Preparation method and application of Armillaria luteo-virens antioxidant active component

An antioxidant activity, Armillaria yellow-green technology, applied in the application, food preparation, antitoxin and other directions, can solve the problems of inability to guarantee consistency, high reagent consumption, non-repeatability, etc., to save extraction cost and Time cost, small reagent consumption, and the effect of improving extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

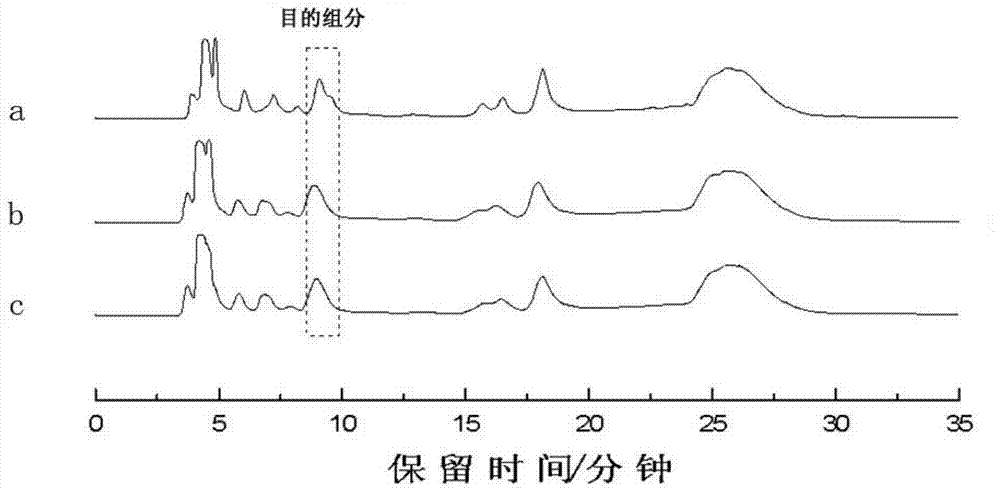

Image

Examples

Embodiment 1

[0036] Example 1: Extraction of Antioxidant Active Components of Armillaria Chrysanthemum Fruiting Body

[0037] The preparation method of the antioxidation active component of Armillaria chrysanthemum fruiting body of this embodiment comprises the following steps:

[0038] (1) Armillaria chrysanthemum fruiting bodies were dried in the shade at room temperature, dried and dehydrated at 60°C, and then ultrafinely pulverized at -20°C for 5 minutes to obtain superfine powder of Armillaria chrysanthemum fruiting bodies.

[0039] (2) Take 1Kg of the above-mentioned superfine powder of Armillaria chrysanthemum fruiting body, add 6.0L of analytical pure water to extract 3 times at 90°C, each time for 1h, and centrifuge at 8000rpm to collect the supernatant. The supernatant is concentrated to a solid content of 50 mg / mL, and 4 times the volume of absolute ethanol is added for alcohol precipitation treatment, and the supernatant is collected by centrifugation, and the alcohol precipita...

Embodiment 2

[0044] Example 2: Extraction of Antioxidant Active Components of Armillaria Chrysanthemum Fruiting Body

[0045] The preparation method of the antioxidation active component of Armillaria chrysanthemum fruiting body of this embodiment comprises the following steps:

[0046] (1) Armillaria chrysanthemum fruiting bodies were dried in the shade at room temperature, dried and dehydrated at 40°C, and then ultrafinely pulverized at 4°C for 20 minutes to obtain superfine powder of Armillaria chrysanthemum fruiting bodies.

[0047] (2) Take 0.3Kg of the above-mentioned superfine powder of Armillaria chrysanthemum fruiting bodies, add 4.5L of analytically pure water to extract 3 times at 60°C, each time for 2h, and centrifuge at 4000rpm to collect the supernatant. The supernatant is concentrated to a solid content of 200 mg / mL, and 9 times the volume of absolute ethanol is added for alcohol precipitation treatment, and the supernatant is collected by centrifugation, and the alcohol pre...

Embodiment 3

[0052] Example 3: Extraction of Antioxidant Active Components of Armillaria Chrysanthemum Fruiting Body

[0053] The preparation method of the antioxidation active component of Armillaria chrysanthemum fruiting body of this embodiment comprises the following steps:

[0054] (1) Armillaria chrysanthemum fruiting bodies were dried in the shade at room temperature, dried and dehydrated at 50°C, and then ultrafinely pulverized at -10°C for 10 minutes to obtain Armillaria chrysanthemum fruiting body superfine powder.

[0055] (2) Take 0.5Kg of the above-mentioned superfine powder of Armillaria chrysanthemum fruiting bodies, add 5L of analytically pure water to extract twice at 75°C, each time for 2h, and centrifuge at 5000rpm to collect the supernatant. The supernatant is concentrated to a solid content of 100mg / mL, and 6 times the volume of absolute ethanol is added for alcohol precipitation treatment, and the supernatant is collected by centrifugation, and the alcohol precipitati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Column length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com