Peony polyphenol extraction process

A peony flower polyphenols and extraction process technology, applied in the field of peony flower polyphenols extraction process, can solve the problems of long extraction time, low extraction rate, and low yield, and achieve short extraction time, increase output value, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0016] The present invention uses pulsed ultrasonic technology to extract phenolic substances in peony petals. The process steps are: weigh 1.0g of peony petal powder and place it in a narrow-necked flask, and add different concentration of ethanol solution (volume fraction of ethanol is 10~70%), put the narrow-mouth beaker in the water bath, and then place the ultrasonic probe in the middle of the liquid. The extraction time is 10~40min, and the ultrasonic extraction is carried out at a temperature of 30 ℃, the power is 1000w.

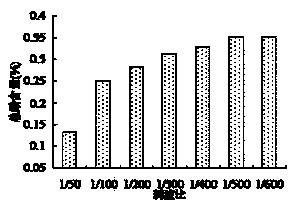

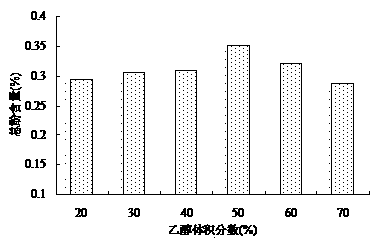

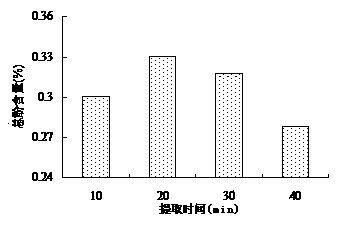

[0017] The present invention selects solid-liquid ratio, extraction time, ethanol volume fraction as single factor, and they are to the extraction rate of polyphenol see figure 1 , figure 2 with image 3 .

[0018] As a preferred solution, the process parameters of the present invention are: the ratio of solid to liquid is 1:500, the volume fraction of ethanol is 50%, the extraction time is 20min, the extraction temperature is 30°C, and the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com