Efficient fuel gas treatment system for boiler

A boiler flue gas and treatment system technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, using liquid separation agent, etc., can solve the problems of low utilization rate of waste water and poor desulfurization effect, etc. Achieve remarkable effect and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

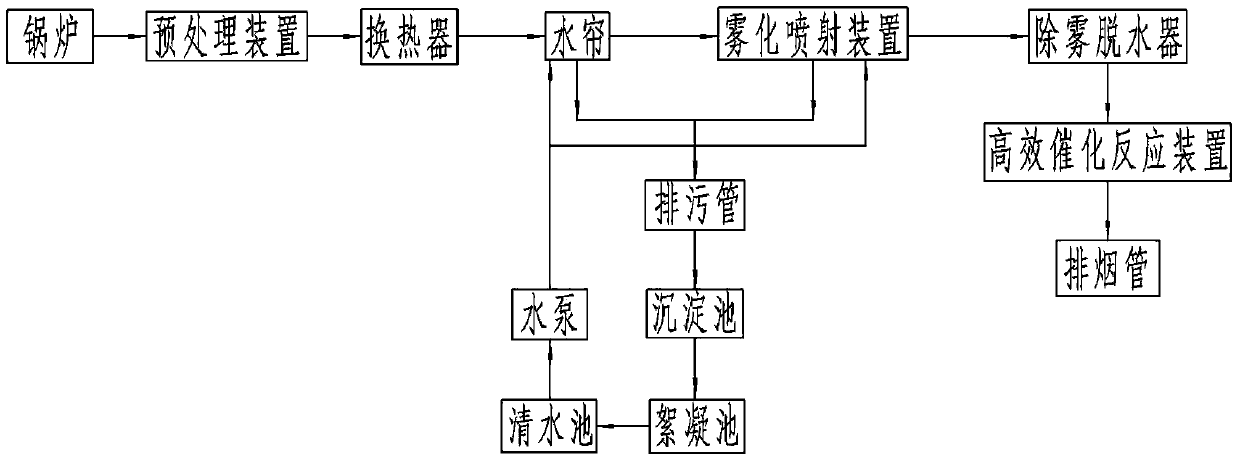

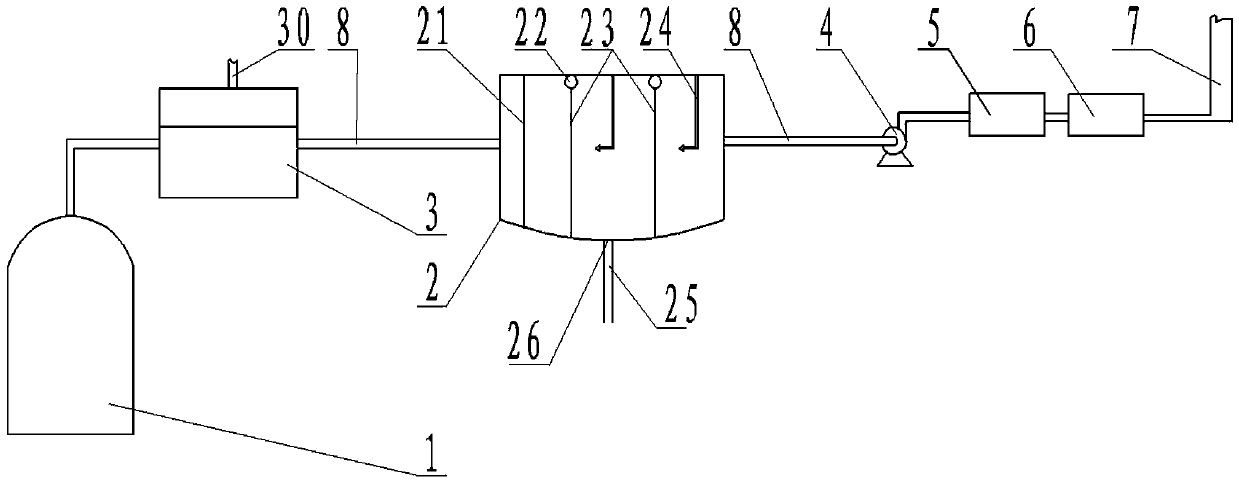

[0030] A high-efficiency boiler flue gas treatment system also includes a water curtain desulfurization and dust collector 2, a water pump and a heat exchanger 3; the boiler 1, heat exchanger 3, water curtain desulfurization and dust collector 2, demister and dehydrator 5 The high-efficiency catalytic reaction device 6 and the smoke exhaust pipe 7 are sequentially connected with a connecting pipe 8; the connecting pipe 8 connecting the water curtain desulfurization and dedusting device 2 to the demisting dehydrator 5 is provided with an exhaust fan 4; The lower part of the desulfurization dust collector 2 is provided with a sewage outlet 26, and the sewage outlet 26 of the water curtain desulfurization dust collector 2 is connected to the sedimentation device through a sewage pipe 25.

[0031] The above-mentioned water curtain desulfurization dust remover 2 is provided with a pretreatment device, a water supply device 22, an atomizing injection device 24 and a water curtain 23;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com