A cupola waste heat utilization dust removal and desulfurization integrated system

A cupola and waste heat technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of complex dust removal equipment, rising flue gas temperature, and large floor space, achieving good dust removal and desulfurization effect, prolonging service life, occupying Small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

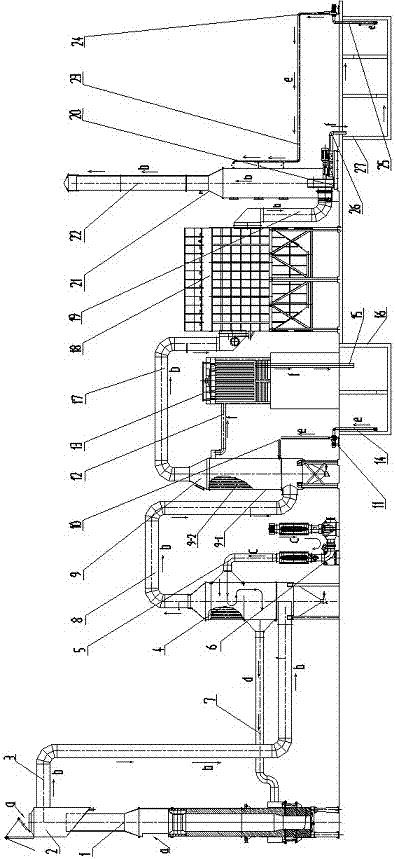

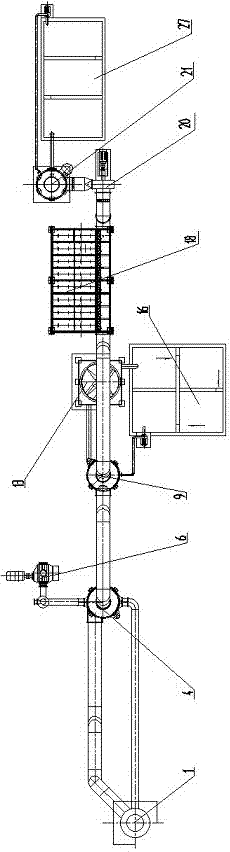

[0029] exist figure 1 , figure 2 Among them, an integrated system for dust removal and desulfurization of cupola waste heat utilization in the present invention includes a cupola 1 with a small amount of air inlet, a spark arrester 2 installed on the top of the cupola and with a small amount of air inlet, and one end is installed on the spark arrester. The first stage flue gas output pipe 3 on the side of the collector, the swirl air heat exchanger 4 installed on the other end of the flue gas output pipe, the air supply pipe 5 installed on the side of the swirl air heat exchanger, installed on The blower 6 on the other end of the air supply pipe, the air supply heat pipe 7 installed between the cupola and the cyclone air heat exchanger, the second-stage flue gas output pipe 8 installed on the top of the cyclone air heat exchanger, The swirling multi-tube water cooler 9 installed at the other end of the second-stage flue gas output pipe, the water supply pipe 10 installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com