Preparation method and production device of catalyst for cyclohexene preparation through benzene selective hydrogenation

A technology for hydrogenation and production equipment selection, applied in the chemical industry, can solve problems such as not being able to meet large-scale industrial production, achieve the effects of saving high-purity nitrogen and high-purity hydrogen, convenient operation, and guaranteed operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

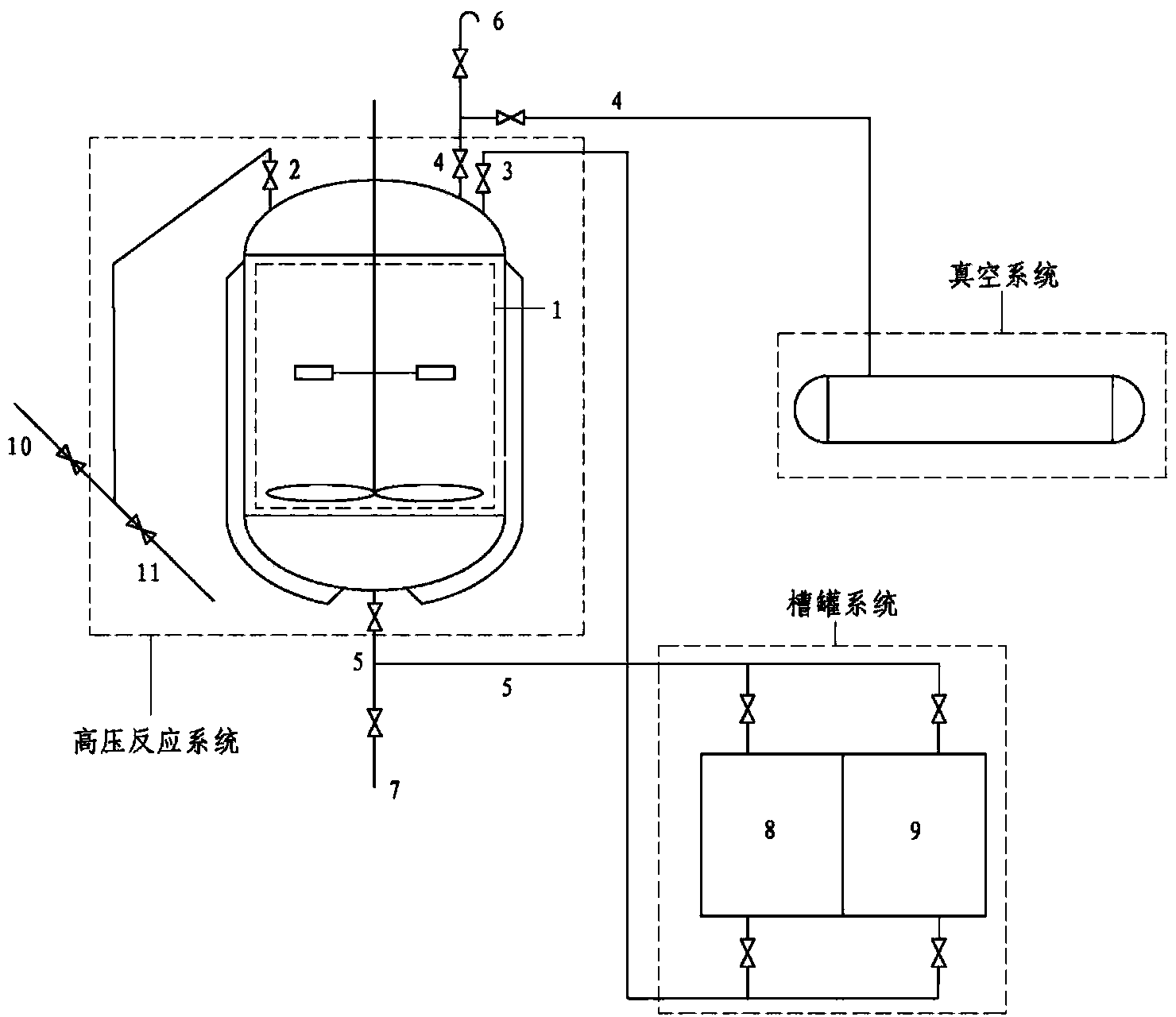

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 catalyst and activity evaluation thereof

[0030] (1) Preparation method

[0031] Salt solution configuration: weigh 15kg RuCl 3 wxya 2 O is put into salt box 8, adds 200L deionized water, dissolves under stirring. Alkali solution preparation: Add about 200L of deionized water at room temperature into the alkali tank 9, add 12kg of NaOH to stir the solution, and control the temperature at 50°C to 60°C.

[0032] Open the vacuum system, first introduce the lye through the liquid feed pipe 3, stir, and then introduce the salt solution. Maintain the temperature at 50° C. to 60° C., and stir for 6 hours. Stand and age for 12 hours.

[0033] Through the inlet pipe 2, high-purity nitrogen is passed into the aged high-pressure reactor for gas replacement, and then high-purity hydrogen is introduced. After the hydrogen pressure reaches 5MPa, heating and stirring are started. During the heating process, hydrogen is replenished in time to maint...

Embodiment 2

[0049] The preparation of embodiment 2 catalyst and activity evaluation thereof

[0050] (1) Preparation method

[0051] Salt solution configuration: weigh 15kg RuCl 3 wxya 2 O is put into the salt box 8, adds 200L deionized water, and dissolves under stirring. Alkali solution preparation: add about 200L room temperature deionized water in the alkali tank in 9, add 12kg NaOH to stir the solution, and control the temperature at 50°C to 60°C.

[0052] Open the vacuum system, first introduce the lye through the liquid feed pipe 3, stir, and then introduce the salt solution. Maintain the temperature at 50° C. to 60° C., and stir for 3 hours. Leave to age for 6 hours.

[0053] Through the inlet pipe 2, high-purity nitrogen is passed into the aged high-pressure reactor for gas replacement, and then high-purity hydrogen is introduced. After the hydrogen pressure reaches 4MPa, heating and stirring are started. During the heating process, hydrogen is replenished in time to maintai...

Embodiment 3

[0063] Example 3 Preparation of Catalyst and Evaluation of Its Activity

[0064] (1) Preparation method

[0065] Salt solution configuration: weigh 15kg RuCl 3 wxya 2 O is put into the salt box 8, adds 200L deionized water, and dissolves under stirring. Alkali solution preparation: Add about 200L of deionized water at room temperature into the alkali tank 9, add 12kg of NaOH to stir the solution, and control the temperature at 50°C to 60°C.

[0066] Open the vacuum system, first introduce the lye through the liquid feed pipe 3, stir, and then introduce the salt solution. Maintain the temperature at 50° C. to 60° C., and stir for 8 hours. Let stand and age for 8 hours.

[0067] Through the inlet pipe 2, high-purity nitrogen is passed into the aged high-pressure reactor for gas replacement, and then high-purity hydrogen is introduced. After the hydrogen pressure reaches 5MPa, heating and stirring are started. During the heating process, hydrogen is replenished in time to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com