Slotted type steam-driven catapult for airplane short-distance take-off

A catapult and steam technology, applied in the field of machinery, can solve problems such as the uncertain future of electromagnetic catapults, uncertainty in the reliability of new technologies, expensive R&D and manufacturing costs, etc., and achieve simple sealing problems, reduced production and processing difficulties, and responsive sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

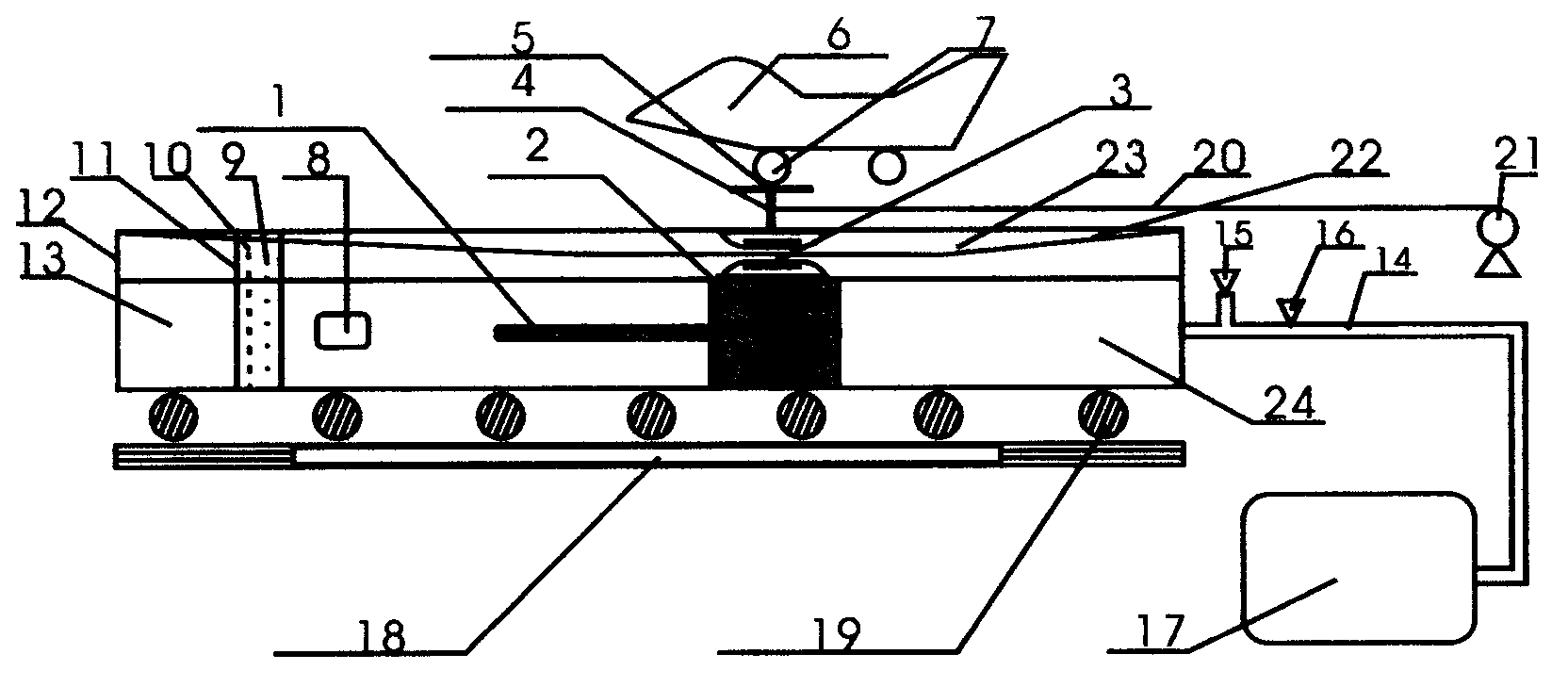

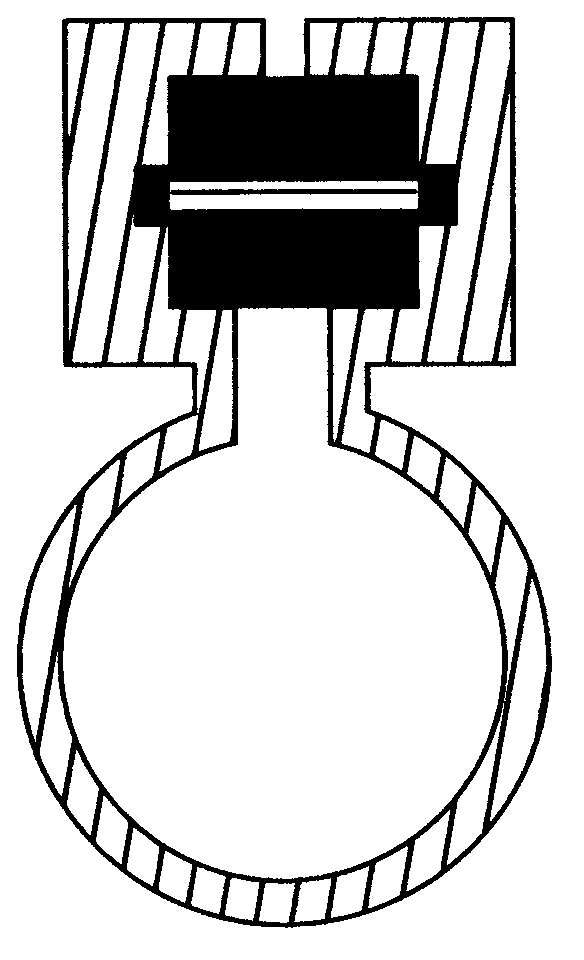

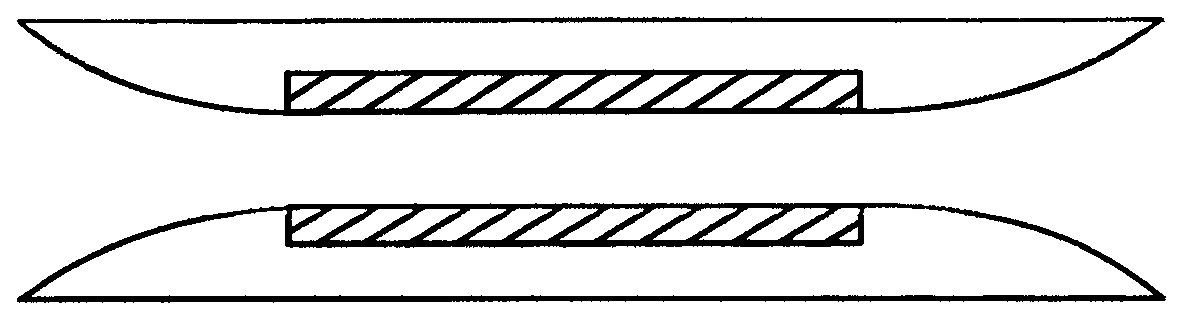

[0037] First, the front wheel 7 of the carrier-based aircraft is fixed on the front wheel limiter 5 of the aircraft, and the direction of the wheels is corrected to ensure that all the wheels are parallel and aligned with the take-off direction. Open the intake valve 16, the high temperature and high pressure steam pushes the piston 2 forward, the piston 2 is connected to the piston ring 3, the piston ring 3 is connected to the shuttle 4, and the shuttle 4 is connected to the aircraft front wheel limiter 5, therefore, the piston 2 , piston ring 3, shuttle 4, aircraft front wheel limiter 5, and shipboard aircraft 6 move forward together under the push of high-temperature and high-pressure steam. After the piston ring 3 slides past, under the action of the expansion force of the high-temperature and high-pressure steam, the sealing strip 22 presses the upper jaw of the square chamber 23 of the cylinder to block the cylinder gap and prevent the steam from leaking. At the moment w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com