Preparation method and application of hexagonal hollow tubular Bi2O(OH)2SO4 photocatalyst

A 2SO4 and photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems that the catalytic performance cannot meet the requirements, etc., and achieve easy batch preparation, cheap and easy-to-obtain raw materials, and novel appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

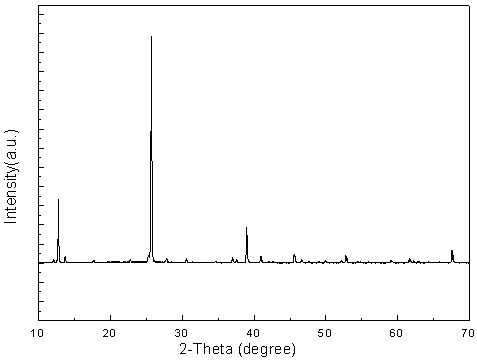

[0022] Add 30 mL of water into the beaker, add 1 mmol of bismuth nitrate pentahydrate under stirring conditions, and stir for 30 min; then add 0.9 mmol of anhydrous sodium sulfite, stir for 1 h, and transfer to a 50 mL autoclave. The autoclave was sealed, kept at 110°C for 24 hours, and cooled to room temperature. The solution in the autoclave was centrifuged to collect the precipitate, and dried at 50°C for 6 hours to obtain material 1. X-ray electron diffraction image from material 1 ( image 3 ), it can be seen that material 1 is a pure phase of Bi 2 O(OH) 2 SO 4 . From the electron micrograph of material 1 ( figure 1 with figure 2 ), it can be seen that material 1 has a novel morphology, which is a hexagonal hollow tube.

Embodiment 2

[0024] Add 30mL of water into the beaker, add 1.5mmol of bismuth nitrate pentahydrate under stirring conditions, and stir for 30min; then add 1mmol of anhydrous sodium sulfite, stir for 1h, and transfer to a 50mL autoclave. The autoclave was sealed, kept at 150°C for 18 hours, and cooled to room temperature. The solution in the autoclave was centrifuged to collect the precipitate, and dried at 60°C for 5 hours to obtain material 2. From the X-ray electron diffraction image of material 2, it can be seen that material 2 is a pure phase of Bi 2 O(OH) 2 SO 4 . From the electron microscope image of material 2, it can be seen that material 2 has a novel shape, which is hexagonal hollow tube.

[0025]

Embodiment 3

[0027] Add 30mL of water into the beaker, add 2mmol of bismuth nitrate pentahydrate under stirring condition, and stir for 30min; then add 1mmol of anhydrous sodium sulfate, stir for 1h, and transfer to a 50mL autoclave. The autoclave was sealed, kept at 180°C for 12 hours, and cooled to room temperature. The solution in the autoclave was centrifuged to collect the precipitate, and dried at 70°C for 3 hours to obtain material 3. From the X-ray electron diffraction image of material 3, it can be seen that material 3 is a pure phase of Bi 2 O(OH) 2 SO 4 . From the electron microscope image of material 3, it can be seen that material 3 has a novel shape, which is a hexagonal hollow tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com