Industrial catalysis method of synthetic nitro substitution compound

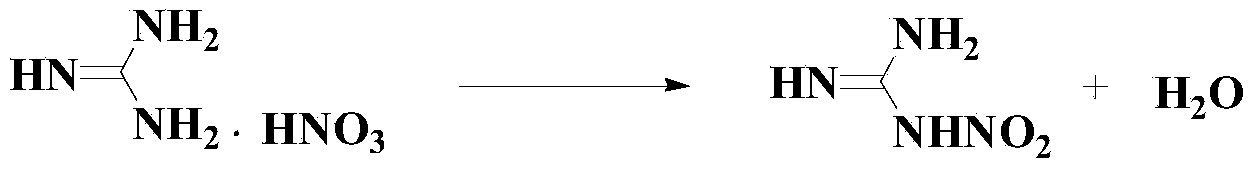

A synthetic method and industrial technology, applied in the field of nitro-substituted compounds, industrial catalysis for the synthesis of nitroguanidine, and the synthesis of nitroguanidine, which can solve the tedious crystallization process or post-processing steps, which are difficult to adapt to large-scale industrial production, Unsatisfactory product yield and other issues, to achieve the effect of efficient catalytic synthesis, broad industrialization prospects and technology transformation value, and reduce reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

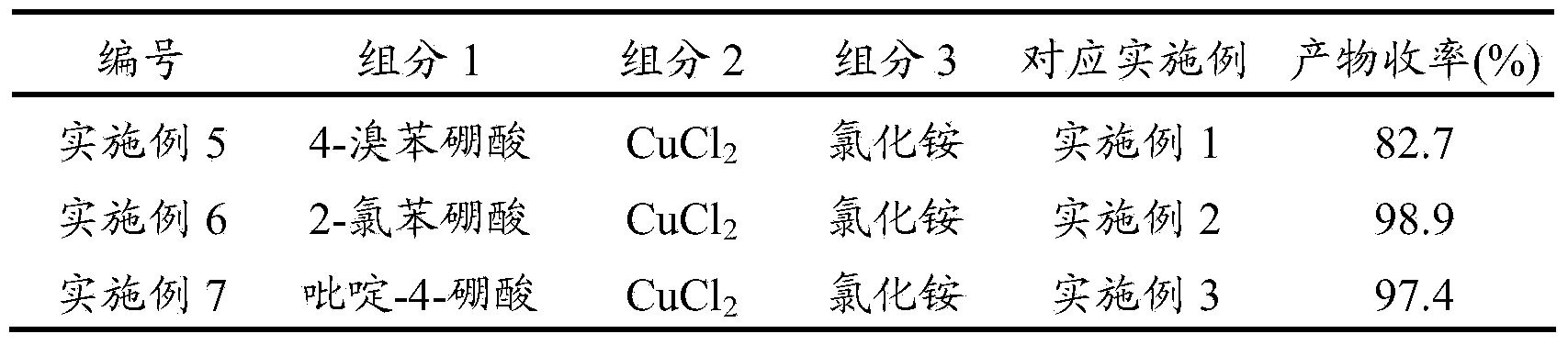

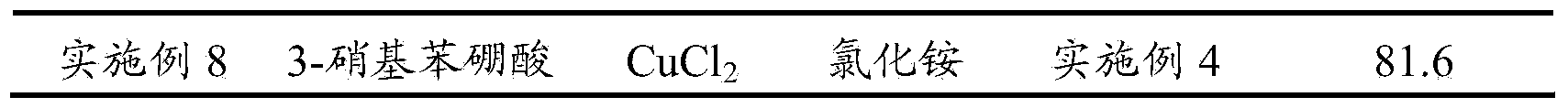

preparation example 1

[0030] Weigh thiophene-3-boronic acid and CuCl according to the molar ratio of 1:1:1 2 And each component of ammonium chloride, place them in a mortar, grind and mix uniformly, to obtain the catalyst used in all the following specific examples of the present invention.

Embodiment 1

[0032] Add 1000g of nitric acid with a mass concentration of 35% to the reactor filled with cooling water, maintain the temperature at 5-10°C, add 500g of guanidine nitrate to it in turn, add 25g of catalyst under stirring, and then add 25g of crown ether 18-crown- 6. Raise the temperature to 28℃, continue to stir the reaction for 30 minutes, the speed of the stirrer is 200r / min, then pour the reaction mixture into ice water, and a large amount of solids will precipitate out. After filtering and washing, the pure nitroguanidine can be obtained. The yield of guanidine was 98.8% and the purity was 98.7% (HPLC).

Embodiment 2

[0034] Add 1200g of nitric acid with a mass concentration of 30% to the reactor with cooling water, maintain the temperature at 5-10℃, add 500g of guanidine nitrate to it in turn, add 25g of catalyst under stirring, and then add 10g of crown ether 15-crown- 5. Raise the temperature to 32℃, continue to stir the reaction for 40 minutes, the speed of the stirrer is 300r / min, then pour the reaction mixture into ice water, and a large amount of solids will precipitate out. After filtering and washing, the pure nitroguanidine can be obtained. The yield of guanidine was 99.4% and the purity was 98.9% (HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com