Low-warping high-rigidity conductive PBT composite material and preparation method

A composite material and high rigidity technology, which is applied in the field of low warpage and high rigidity conductive PBT composite material and its preparation, can solve the problem of not mentioning the influence of physical and mechanical properties and conductive properties of PBT materials, and not mentioning the conductive properties of PBT materials High rigidity, excellent formability, and improved warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

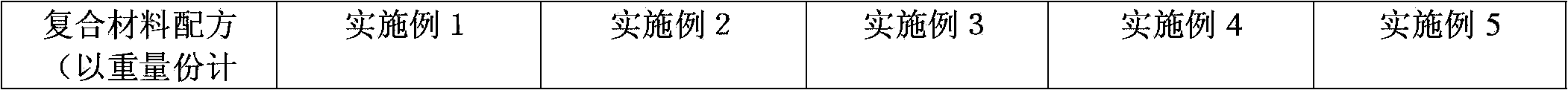

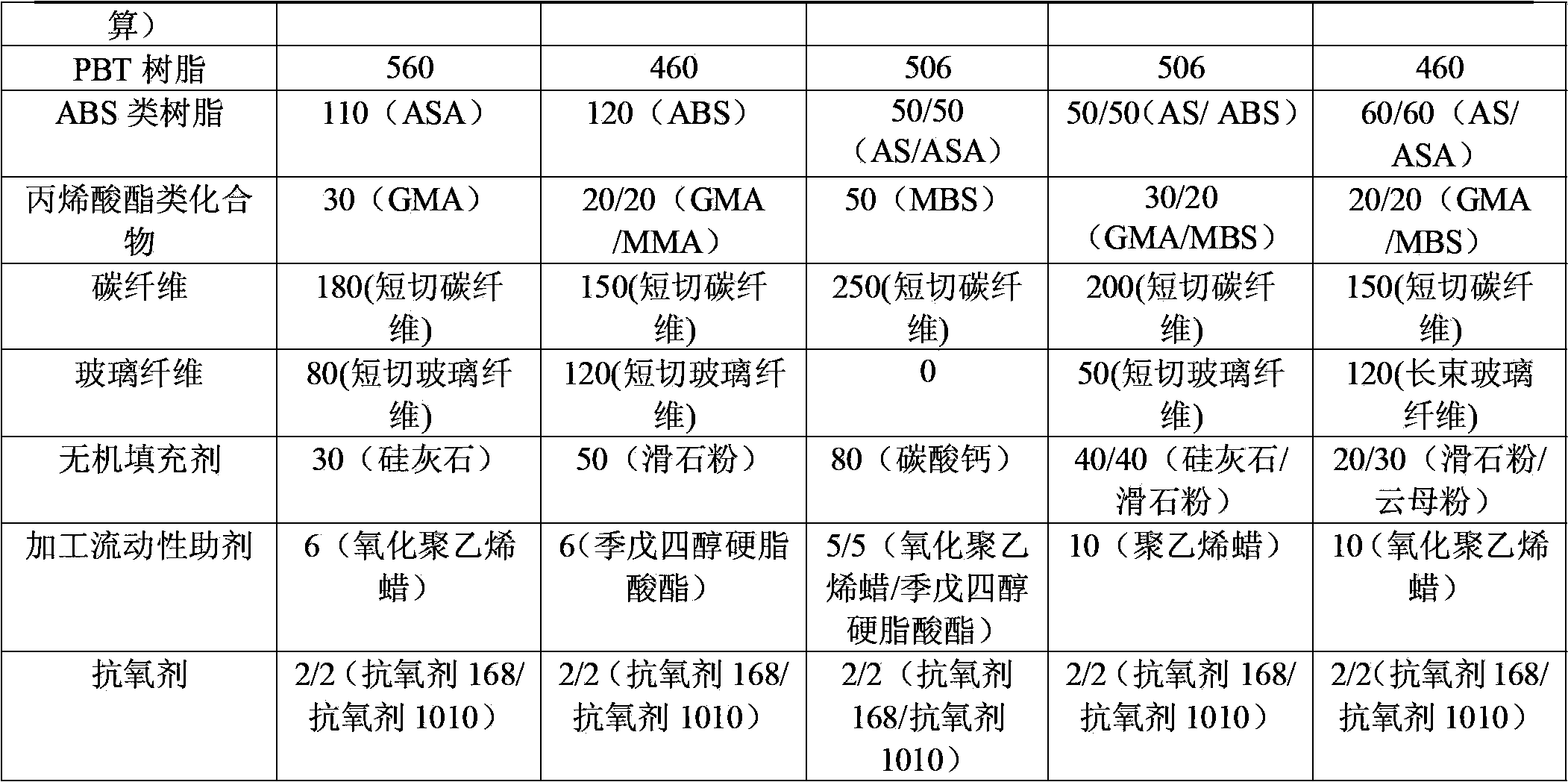

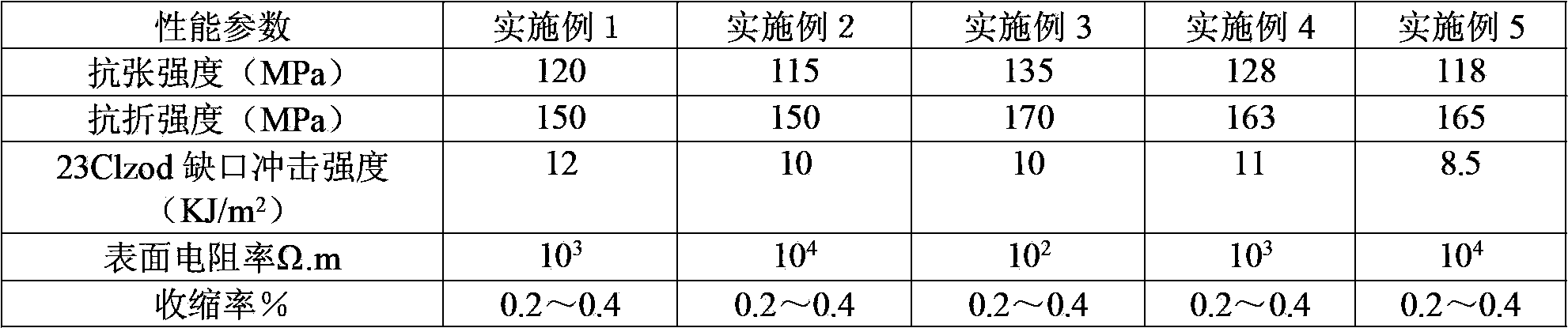

Embodiment 1

[0043] The following components in parts by weight (1 part=100g): 560 parts of PBT, 30 parts of GMA, 110 parts of ASA, 30 parts of wollastonite, 6 parts of oxidized polyethylene wax, 2 parts of antioxidant 168, 2 parts Antioxidant 1010 is dry-blended in a high-speed mixer at room temperature, and placed in a single-screw extruder, and then enters a twin-screw extruder after melt extrusion, and 180 parts of chopped carbon fiber, 80 parts of chopped carbon fiber Glass fiber blending, the screw speed is 100Hz, melted and extruded at 225-235°C, and granulated to make a composite material. The heating zones of the single screw are: the first zone is 225-230°C, the second zone is 230-235°C, The third zone is 230~235℃, the fourth zone is 230~235℃; the heating zones of the twin-screw are respectively: the first zone is 200~210℃, the second zone is 210~235℃, the third zone is 210~235℃, and the fourth zone is 215~230℃ , 210-235°C in the fifth zone, 210-235°C in the sixth zone, 215-230°C...

Embodiment 2

[0045] The following components in parts by weight (1 part=100g): 460 parts of PBT, 20 parts of GMA, 20 parts of MMA, 120 parts of ABS, 50 parts of talcum powder, 6 parts of pentaerythritol stearate, 2 parts of antioxidant 168. Two parts of antioxidant 1010 were dry-blended in a high-speed mixer at room temperature, placed in a single-screw extruder, melted and extruded and then entered into a twin-screw extruder unit, and mixed with 150 parts of chopped carbon fiber, 120 parts of chopped glass fibers are blended, the screw speed is 100Hz, melted and extruded at 225-235°C, and granulated to make a composite material. The heating zones of the single screw are: the first zone 225-230°C, the second zone 230 ~235°C, three zones 230~235°C, four zones 230~235°C; twin-screw heating zones are: zone one 200~210°C, zone two 210~235°C, zone three 210~235°C, zone four 215~230℃, 210~235℃ in the fifth zone, 210~235℃ in the sixth zone, 215~230℃ in the seventh zone, 210~225℃ in the eighth zon...

Embodiment 3

[0047] The following components in parts by weight (1 part=100g): 506 parts of PBT, 50 parts of MBS, 50 parts of AS, 50 parts of ASA, 80 parts of calcium carbonate, 5 parts of oxidized polyethylene wax, 5 parts of pentaerythritol stearic acid Ester, 2 parts of antioxidant 168, and 2 parts of antioxidant 1010 were dry mixed in a high-speed mixer at room temperature, and placed in a single-screw extruder, and then entered into a twin-screw extruder after melt extrusion. Blended with 250 parts of chopped carbon fiber, the screw speed is 100Hz, melted and extruded at 225-235°C, and granulated to make a composite material. The heating zones of the single screw are: the first zone 225-230°C, the second zone 230 ~235°C, three zones 230~235°C, four zones 230~235°C; twin-screw heating zones are: zone one 200~210°C, zone two 210~235°C, zone three 210~235°C, zone four 215~230℃, 210~235℃ in the fifth zone, 210~235℃ in the sixth zone, 215~230℃ in the seventh zone, 210~225℃ in the eighth zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com