Complex enzyme water soaking agent for tanning

A compound enzyme preparation and water soaking agent technology, which is applied in the field of leather chemicals, can solve the problems of uneven water return and less fiber interstitial removal, and achieve the effects of shortening soaking time, speeding up removal, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

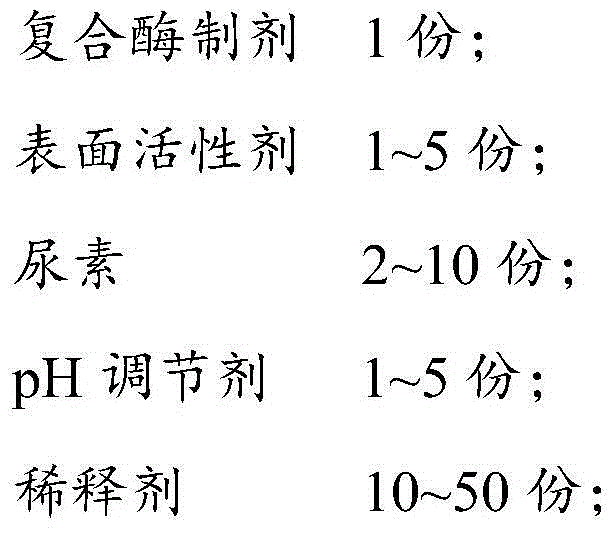

Method used

Image

Examples

Embodiment 1

[0026] Weigh 1.5 parts of Lvweikang Leveking-01 alkaline lipase at 10,000 international units / g, 1.5 parts of Lvweikang Leveking-PF01 alkaline protease at 50,000 international units / g, and green Mix 1.0 part of Weikang Leveking-001 glucoamylase, 1.0 part of A.S1.398 neutral protease of 50,000 international units / gram, and mix the above enzyme preparations evenly to obtain a compound enzyme preparation.

[0027] Weigh 1.0 parts of compound enzyme preparation, 2.0 parts of sodium lauryl sulfate, 5.0 parts of urea, 1.0 parts of sodium carbonate, 16 parts of cornstarch, 5.0 parts of sodium metapolyphosphate, and 10.0 parts of sodium sulfate, and mix them uniformly to obtain tanning Use compound enzyme water soaking agent. The enzyme activity of lipase in the composite enzyme soaking agent is 75 international units / g, the enzyme activity of protease is 625 international units / g, and the enzyme activity of glucoamylase is 250 international units / g.

[0028] The composite enzyme wat...

Embodiment 2

[0036] Weigh 5.0 parts of Lvweikang Leveking-01 alkaline lipase at 10,000 IU / g, 3.0 parts of 2709 alkaline protease at 50,000 IU / g, and Lvweikang Leveking-001 at 50,000 IU / g 1.0 part of glucoamylase, 1.0 part of 166 neutral protease of 50,000 international units / g, and the above enzyme preparations were evenly mixed to obtain a compound enzyme preparation.

[0037] Weigh 1.0 parts of compound enzyme preparation, 2.0 parts of sodium dodecylsulfonate, 8.0 parts of urea, 2.0 parts of sodium carbonate, 15 parts of cornstarch, 2.0 parts of kaolin, 2.0 parts of sodium metapolyphosphate, and 8.0 parts of sodium sulfate, and mix After uniformity, a compound enzyme water soaking agent for tanning is obtained. The enzyme activity of lipase in the composite enzyme water soaking agent is 125 international units / g, the enzyme activity of protease is 500 international units / g, and the enzyme activity of glucoamylase is 125 international units / g.

[0038] The compound enzyme water soaking a...

Embodiment 3

[0046] Weigh 3.0 parts of Lvweikang Leveking-01 alkaline lipase at 10,000 IU / g, 2.0 parts of Lvweikang Leveking-PF01 alkaline protease at 50,000 IU / g, and Lvweikang Leveking-PF01 alkaline protease at 50,000 IU / g Mix 2.0 parts of Weikang Leveking-001 glucoamylase, 3.0 parts of 166 neutral protease at 50,000 international units / g, and mix the above enzyme preparations evenly to obtain a compound enzyme preparation.

[0047] Weigh 1.0 parts of compound enzyme preparation, 1.0 parts of Remibond, 2.0 parts of urea, 1.0 parts of sodium carbonate, 8.0 parts of corn starch, 1.0 parts of sodium metapolyphosphate, 3.0 parts of diatomaceous earth, and 3.0 parts of sodium sulfate, and mix well A compound enzyme water soaking agent for tanning was obtained. The enzyme activity of lipase in the composite enzyme water soaking agent is 150 international units / g, the enzyme activity of protease is 1250 international units / g, and the enzyme activity of glucoamylase is 500 international units / g....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com