Polycrystal ingot casting furnace for preventing silicon leakage in thermal field

A polycrystalline ingot, heat-proof technology, applied in the direction of polycrystalline material growth, single crystal growth, crystal growth, etc., can solve the problem of stainless steel corrosion, and achieve the effect of isolating heat outflow, good effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

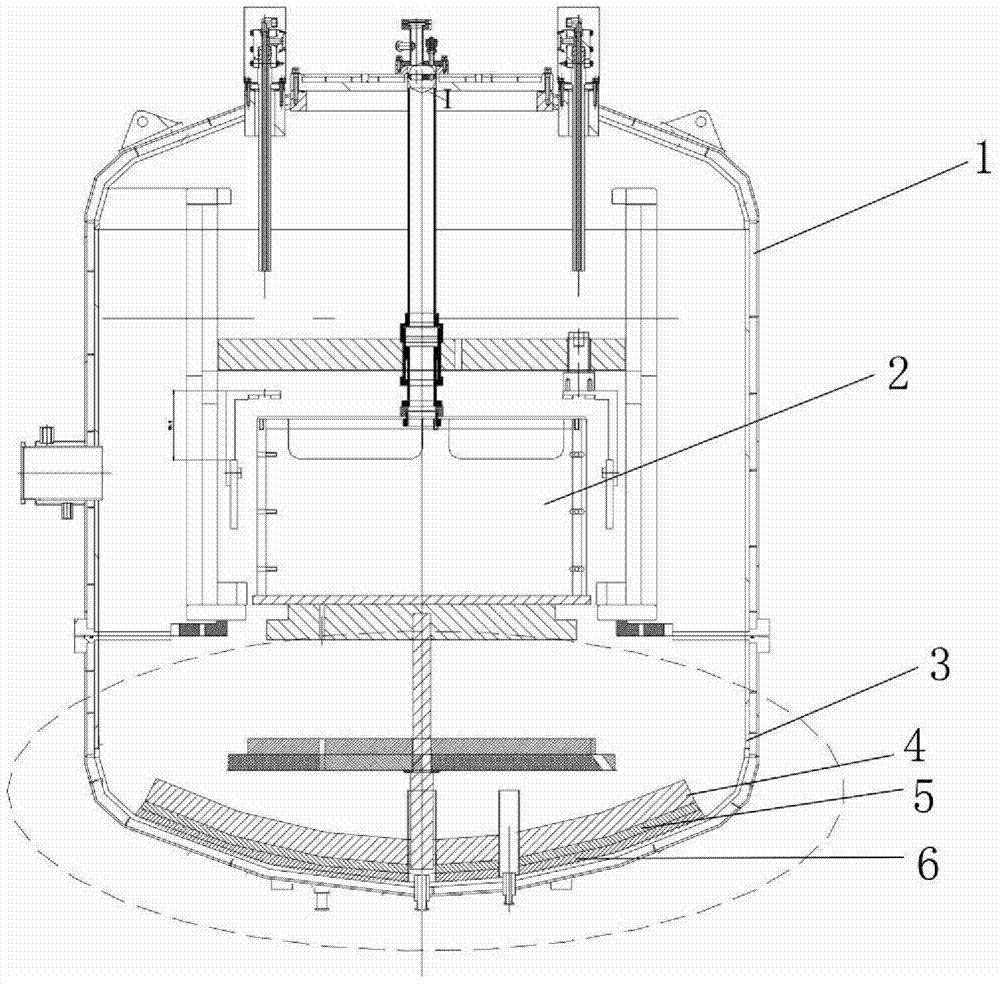

[0016] Such as figure 1 The polycrystalline ingot furnace for preventing silicon leakage in the heat field includes a furnace body 1 and a ceramic crucible 2 in the furnace body 1. A heat exchange block is arranged at the bottom of the ceramic crucible 2, and a width of about 3.5 mm is arranged inside the furnace body 1. The interlayer 3 is provided with an anti-leakage silicon mechanism at the bottom of the furnace body 1. The anti-leakage silicon mechanism includes three layers including an upper layer of alumina felt 4, a middle layer of carbon fiber woven cloth 5 and a lowermost layer of glass backing plate 6. In addition, it should be noted that the aluminum oxide felt 4 , the carbon fiber woven cloth 5 and the glass backing plate 6 are all existing materials, and thus do not belong to the protection scope of the patent.

Embodiment 2

[0018] The difference from Example 1 is that the thickness of the interlayer 3 is 4.0 mm. The rest of the working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com