Melt spinning method using x-ray on-line synchronous detection

A simultaneous detection and melt-spinning technology, which is applied in the direction of melt-spinning, complete sets of equipment for the production of artificial threads, textiles and papermaking, etc. Adding problems such as devices for observing microstructures to achieve the effect of being convenient for scientific research, easy to implement, and reasonable in structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

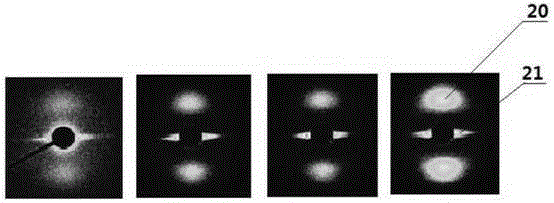

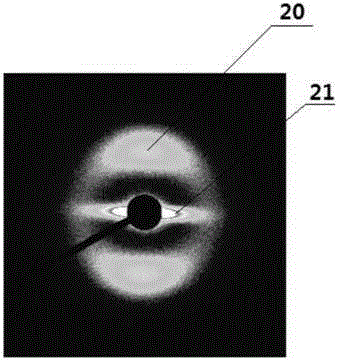

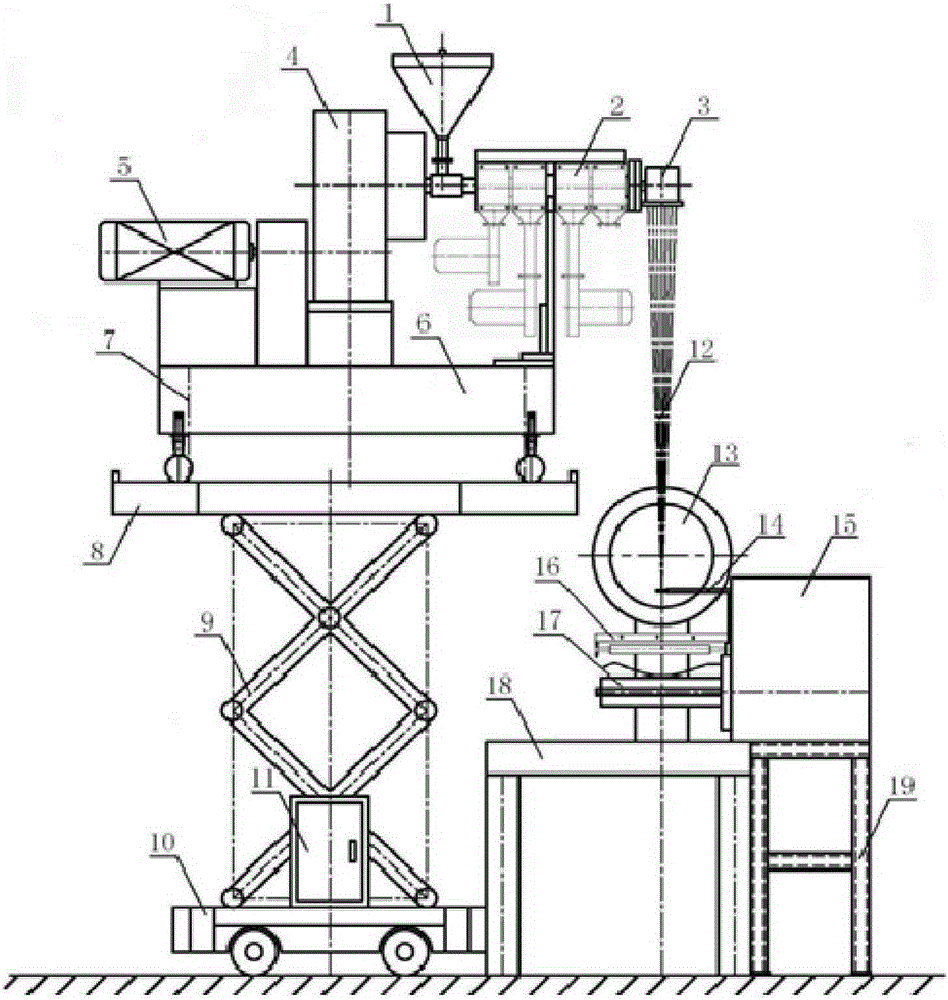

[0086] Such as figure 1 with figure 2 As shown, the X-ray small-angle scattering diagram of isotactic polypropylene in the melt-spinning process was obtained at the Shanghai Synchrotron Radiation Light Source Small-Angle Scattering Station by using the melt-spinning method using X-ray online synchronous detection.

[0087] The isotactic polypropylene spinning temperature is 230°C, the winding speed is 300m / min, and the lifting table is movable. figure 2 shows the X-ray small-angle scattering diagrams of the obtained fiber tow 12 at positions 39 cm, 49 cm, 69 cm, and 99 cm away from the spinning assembly, respectively.

[0088] Such as figure 2 As shown, according to the obtained X-ray small-angle scattering pattern, the long-term information of the fiber at different positions can be calculated 20, so that the crystallization situation at different positions can be deduced, and at the same time, the spinning process can be inferred according to the position and intensity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com