Oil field surface wet steam flow dry degree measuring device

A measurement device, wet steam technology, applied in measurement device, liquid/fluid solid measurement, volume measurement, etc., can solve the problems of two-phase flow pattern change, large structure volume, low measurement accuracy, etc., and achieves reduced representativeness, The effect of small weight and volume and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

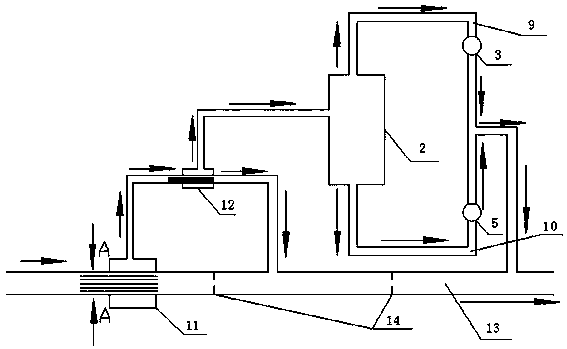

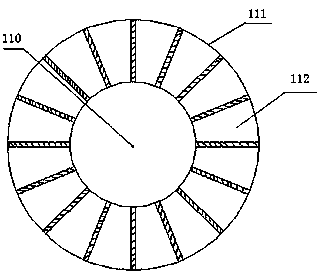

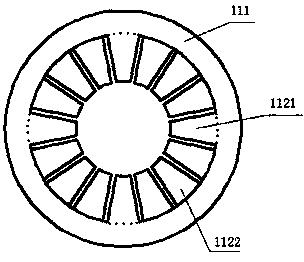

[0016] The wet steam flow dryness measuring device on the surface of the oil field includes a flow divider 1, a separator 2 and a measuring mechanism, a data acquisition system 6, a data display and storage system 7, the entrance of the flow divider 1 and the separator 2 connected, the measuring mechanism is provided with measuring components 3 and 5 in the outlet connecting pipeline of the separator 2, and the flow divider 1 is a multi-point multi-stage shunt device; the multi-point multi-stage shunt device Including the main pipeline 13 and two flow distribution mechanisms 11, 12, wherein the flow distribution mechanism 11 is arranged at the port of the main pipeline 13, and the outlet of the flow distribution mechanism 11 is connected with the inlet of the main pipeline 13 and another flow distribution mechanism 12 respectively connected, the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com