Preparation method of LTCC (Low Temperature Co-fired Ceramic) section sample

A section and sample technology, which is applied in the field of LTCC section sample preparation, can solve the problem of inability to accurately reflect the quality of LTCC sample perfusion process and process control quality, the difficulty of observing the interface morphology of each layer, and insufficient cleaning of the boundary lines of each layer of materials, etc. Problems, to achieve good engineering application promotion value, short test cycle, and improve the effect of clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further introduced below by taking the LTCC filter as an example in conjunction with the accompanying drawings.

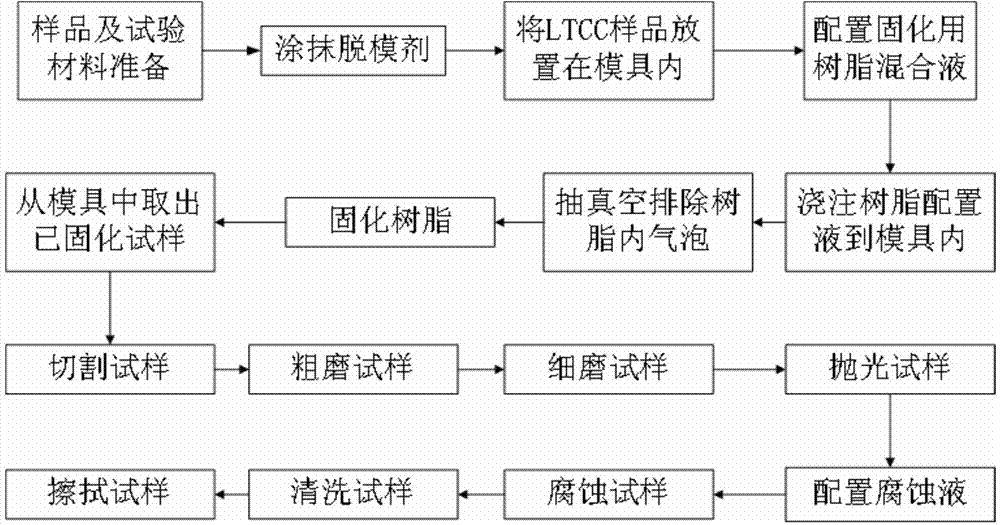

[0069] Such as figure 1 As shown, taking the LTCC filter through-hole section sample preparation as an example, describe the preparation method of the LTCC product section sample preparation according to the present invention,

[0070] The sample preparation step is completed by the cooperation of the sample fixing stage, the sample grinding and polishing stage and the sample corrosion stage, and the implementation steps of the sample fixing stage are as follows:

[0071] Step (1) Prepare LTCC filter samples to be prepared, molds (containers for inlaying samples), mold release agents, epoxy resins and curing agents, hydrochloric acid and nitric acids, glass rods, alcohol cotton balls, etc.;

[0072] Step (2) Apply the release agent prepared in step (1) to the inner surface of the mold;

[0073] Step (3) Place the LTCC sample p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com