Battery cathode slurry and preparation method of battery cathode slurry

A technology of battery negative electrode and negative electrode active material, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of low compaction density of pole pieces, defects in cycle performance, and difficult dispersion of ingredients, so as to compensate for the decline in electrical conductivity, Improved flow properties and improved consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

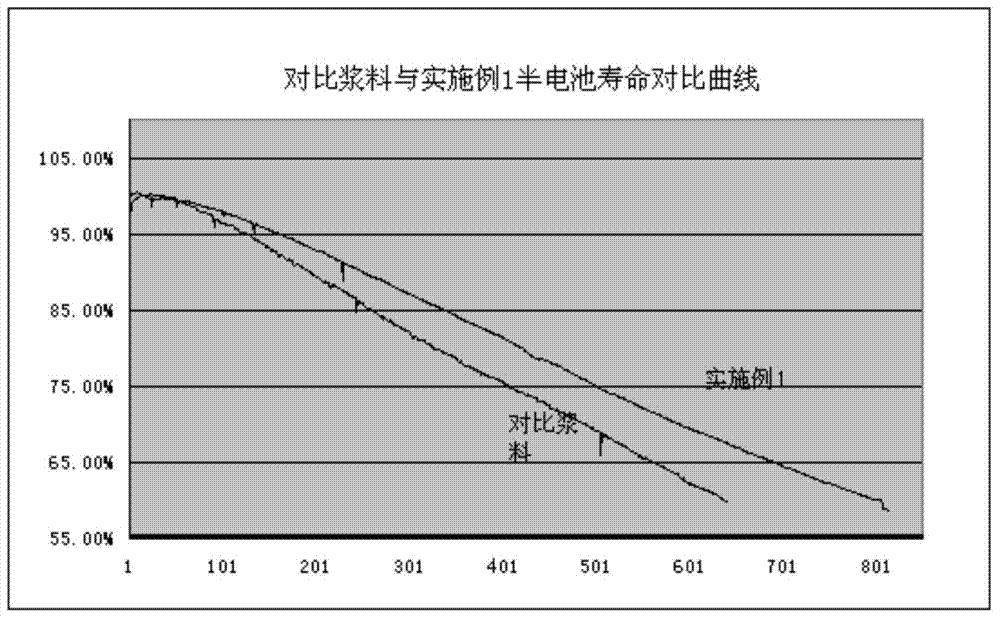

Embodiment 1

[0040] Selection of negative electrode slurry components (parts by weight)

[0041]

[0042] Preparation of negative electrode slurry:

[0043] 1) Alloy treatment: add 100g of hydrogen storage alloy to potassium borohydride as a reducing agent and perform constant temperature treatment under hot alkali conditions to form a nickel-coated layer on the surface of the alloy.

[0044] 2) Preparation of binder: Weigh 0.7g of dry powder binder 1 in a beaker according to the proportion, stir evenly, and prepare a binder glue solution with a solid content of (2%-4%), and let it stand for later use.

[0045] 3) Preparation of auxiliary liquid: Mix 9.2g of conductive agent and 0.5g of antioxidant, add solvent and stir evenly, then add HPMC, stir with double planetary mixer, and prepare auxiliary liquid with solid content of 17%-19%. After stirring evenly, let it stand at room temperature for 12-15 hours and set aside.

[0046] 4) Slurry: Add the pretreated AB alloy powder, stir with...

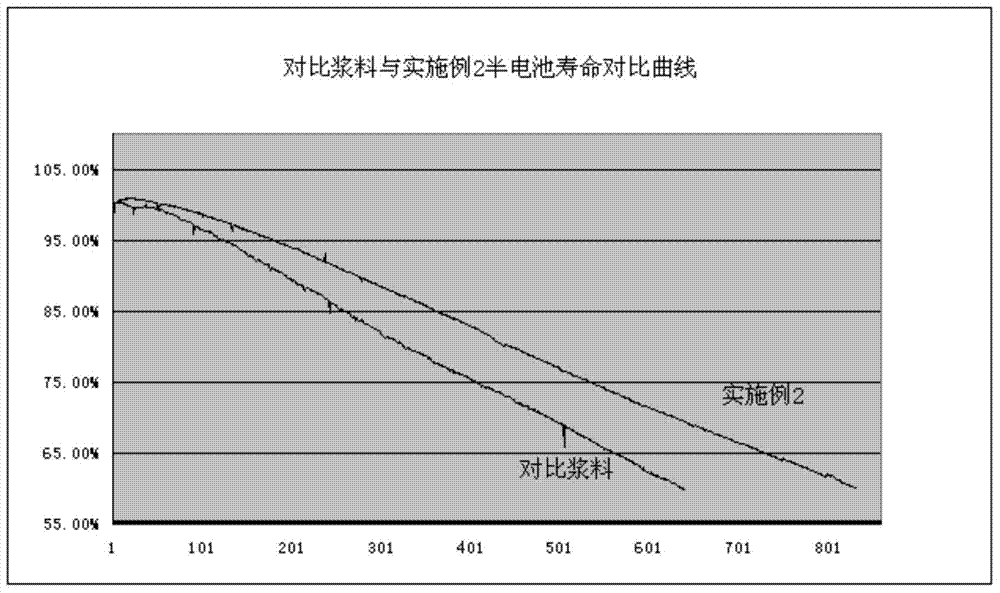

Embodiment 2

[0048] Selection of negative electrode slurry components (parts by weight)

[0049]

[0050] Preparation of negative electrode slurry:

[0051] 1) Alloy treatment: add 100g of hydrogen storage alloy to sodium borohydride as a reducing agent and perform constant temperature treatment under hot alkali conditions to form a nickel-coated layer on the surface of the alloy.

[0052]2) Preparation of binder: Weigh 0.7g of dry powder hydrophilic binder hydroxypropyl methylcellulose (HPMC) and sodium polyacrylate in a beaker, stir evenly, and prepare a solid content of (2% -4%) adhesive glue solution 1, set aside for later use.

[0053] 3) Auxiliary liquid configuration: Mix 9.5g of conductive agent and 0.5g of antioxidant, add solvent and stir evenly, then add binder, stir with double planetary mixer, and prepare auxiliary liquid with solid content of 17%-19%. liquid. After stirring evenly, let it stand at room temperature for 12-15 hours and set aside.

[0054] 4) Slurry: add ...

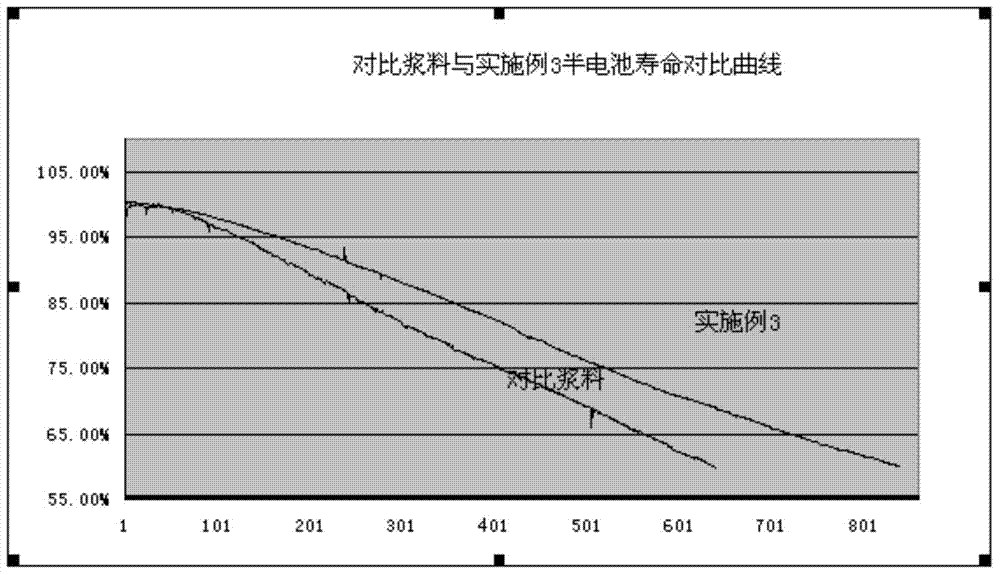

Embodiment 3

[0056] Selection of negative electrode slurry components (parts by weight)

[0057]

[0058] Preparation of negative electrode slurry:

[0059] 1) Alloy treatment: Add 100g of hydrogen storage alloy to sodium hypophosphite as a reducing agent and perform constant temperature treatment under hot alkali conditions to form a nickel-coated layer on the surface of the alloy.

[0060] 2) Preparation of binder: Weigh 0.7g dry powder hydroxypropyl methylcellulose (HPMC) in a beaker according to the proportion, stir evenly, and prepare a binder glue with a solid content of (2%-4%) , set aside for later use.

[0061] 3) Auxiliary liquid configuration: Mix 6.95g of conductive agent and 0.5g of antioxidant, add solvent and stir evenly, then add binder 1, stir with double planetary mixer, and prepare a solid content of 17%-19% auxiliary liquid. After stirring evenly, let it stand at room temperature for 12-15 hours and set aside.

[0062] 4) Slurry: Add the pretreated alloy powder, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com