Brass alloy coverage slag removal agent and preparation method thereof

A technology covering slag cleaning agent and brass alloy, which is applied in the field of casting flux, can solve the problems of high copper content, resource waste, agglomeration, etc., and achieve the effect of reducing the content of bright copper and good spreadability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

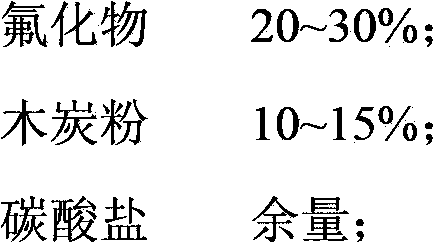

[0023] The mass ratio of components is:

[0024]

[0025] After weighing the above components, put into the mixer according to the principle of putting in the ingredients with large ratio first, and then put in the ingredients with small ratio. Among them, sodium chloride and potassium chloride play the role of covering, and cryolite and fluorite play the role of refining , calcium carbonate and magnesium carbonate play the role of supplementary refining agent; the mixture is dried in an oven, and its moisture is controlled within 0.5wt%; finally, it is ground into powder, and its particle size is within 80 meshes, which is the required Brass alloy covered slag remover.

[0026] Subsequent processing process description:

[0027] Add copper material to the furnace → melt (about 1000 degrees) → stir (2-3 minutes) → add slag cleaning agent (the amount is 0.3-0.5% of the copper weight) → fully stir (1-2 minutes) → keep warm and remove slag

Embodiment 2

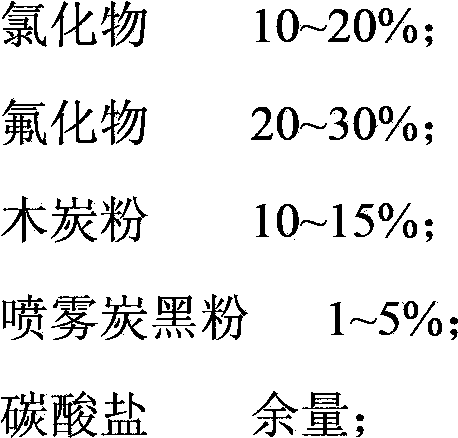

[0029] The group distribution ratio is:

[0030]

[0031] All the other preparation methods are the same as in Example 1

Embodiment 3

[0033] The group distribution ratio is:

[0034]

[0035]

[0036] All the other preparation methods are the same as in Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com