Narrow Gap Metal Active Gas Shielded Arc Welding Process

An active gas and narrow gap technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of not meeting the welding process well, large structure size, and large tendency of cold cracking, etc., and achieve the reduction of welding filling , large tendency of cold cracking and large amount of groove filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

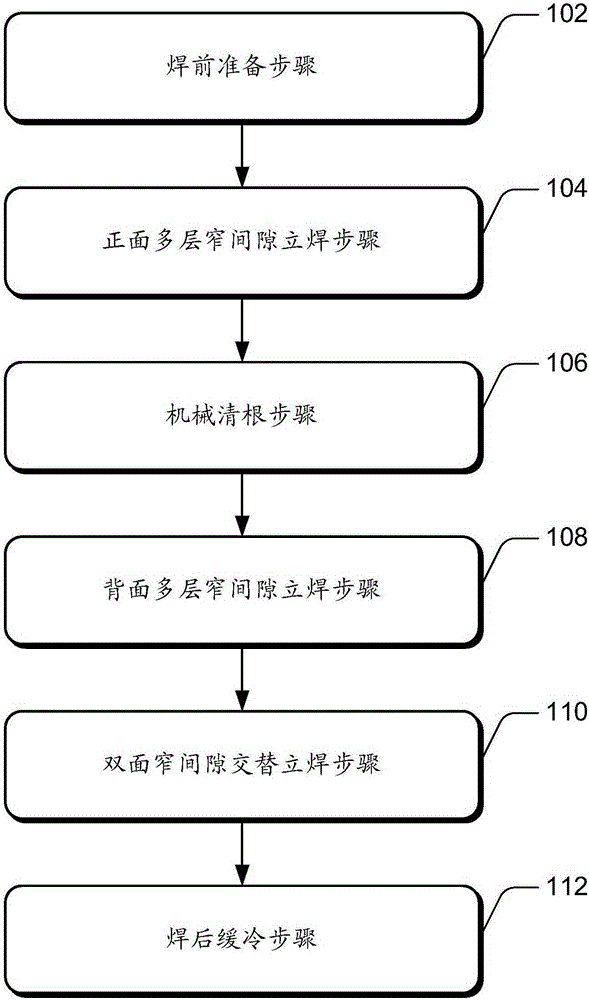

[0028] refer to figure 1 As shown, the present invention discloses a narrow gap melting electrode active gas shielded arc welding process, including:

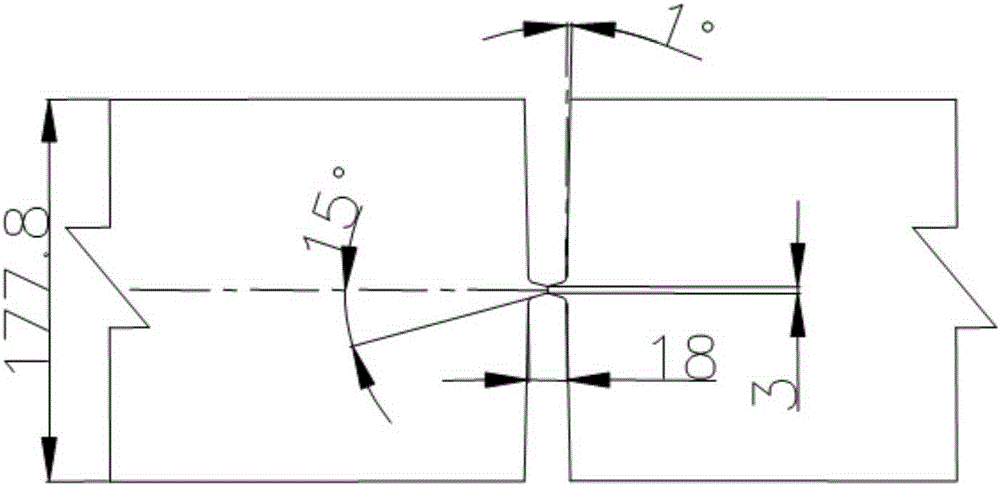

[0029] 102. Preparation steps before welding. The pre-weld preparation steps include the groove processing process, the pretreatment process, the preheating process and the groove assembly process. In one embodiment, the angle of the groove obtained in the groove processing process is 0.5°-2°, the blunt edge at the root is 1-4 mm, and the pair gap is 16-20 mm. figure 2 Disclosed is a processed groove structure in a narrow gap metal active gas shielded arc welding process according to an embodiment of the present invention. exist figure 2 In the shown embodiment, the angle of the groove obtained during the groove processing process is 1°, the blunt edge of the root is 3mm, the pair gap is 18mm, the inclination angle of the root is 15°, and the plate thickness is 177.8mm. The pretreatment process includes removing rust and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com