A kind of preparation method of carbon-coated photothermal conversion nanomaterial

A technology of photothermal conversion and nanomaterials, applied in the preparation/purification of carbon, nanotechnology, nanotechnology, etc., can solve the problems of limited biological application, high toxicity, complicated preparation process, etc., and achieve high near-infrared light absorption performance, The effect of preventing agglomeration and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Add CuCl to the beaker 2 2H 2 O (0.17g, 1mmol), and dissolved in 1000ml distilled water, stirred continuously to obtain a light blue solution. Then DMSA (0.9g, 5mmol), NaOH (0.4g, 10mmol), Na 2 S·9H 2 Add O (0.24g, 1mmol) into 10ml of distilled water one by one, stir evenly, pour the mixture into the above light blue solution, and stir at room temperature for 5 minutes, then raise the temperature to 85°C, stir magnetically for 25 minutes to obtain dark green The product was centrifuged several times with distilled water and methanol solution to obtain DMSA-coated CuS nanoparticles. Add the above particles into 35ml of sodium sulfide solution with pH = 12, after ultrasonic dispersion, pour into a 50ml hydrothermal reaction kettle, react at 210°C for 6 hours at high temperature, finally centrifuge several times with distilled water and methanol solution, and dry naturally Finally, carbon-coated CuS nanoparticles were obtained.

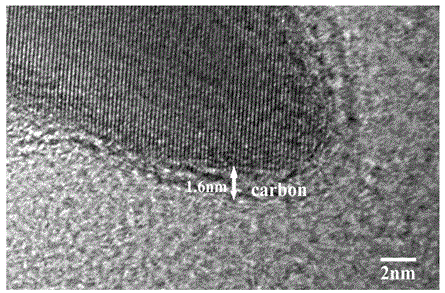

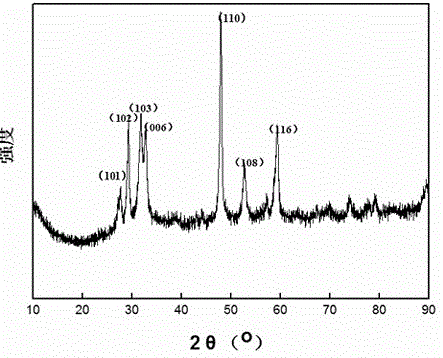

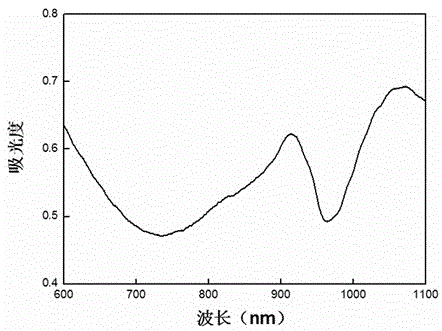

[0019] The high-resolution transmissio...

Embodiment 2

[0024] Add CuCl to the beaker 2 2H 2 O (0.25g, 1.5mmol), and dissolved in 1000ml distilled water, stirred continuously to obtain a light blue solution. Then DMSA (1.25g, 7mmol), NaOH (0.4g, 10mmol), Na 2 S·9H 2 O (0.36g, 1.5mmol) was added into 10ml of distilled water successively, and after stirring evenly, the mixed solution was poured into the above light blue solution, and after stirring at room temperature for 5 minutes, the temperature was raised to 90°C, and magnetic stirring was carried out for 20 minutes to obtain deep The green product was centrifuged several times with distilled water and methanol solution to obtain DMSA-coated CuS nanoparticles. Add the above particles into 35ml of sodium sulfide solution with pH = 11, after ultrasonic dispersion, pour into a 50ml hydrothermal reaction kettle, react at 210°C for 5 hours at high temperature, finally centrifuge several times with distilled water and methanol solution, and dry naturally Finally, carbon-coated CuS ...

Embodiment 3

[0026] Add CuCl to the beaker 2 2H 2 O (0.08g, 0.5mmol), and dissolved in 500ml of distilled water, stirred continuously to obtain a light blue solution. Then DMSA (0.45g, 2.5mmol), NaOH (0.2g, 5mmol), Na 2 S·9H 2 O (0.12g, 0.5mmol) was added into 5ml of distilled water successively, after stirring evenly, the mixed solution was poured into the above light blue solution, and after stirring at room temperature for 5 minutes, the temperature was raised to 85°C, and magnetic stirring was carried out for 20 minutes to obtain deep The green product was centrifuged several times with distilled water and methanol solution to obtain DMSA-coated CuS nanoparticles. Add the above particles into 35ml of sodium sulfide solution with pH=12.5, after ultrasonic dispersion, pour into a 50ml hydrothermal reaction kettle, react at 210°C for 5 hours at high temperature, finally centrifuge several times with distilled water and methanol solution, and dry naturally Finally, carbon-coated CuS na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com