Silver halide based photoinitiator and application thereof to light-induction unsaturated olefin monomer polymerization

A photoinitiator and olefin monomer technology, which is applied in the field of photoinitiated polymer polymerization, can solve the problems of high price, large volume shrinkage, and slow curing speed, and achieve fast reaction speed, mild reaction conditions, and anti-aggregation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] With 1wt% sorbitan monooleate polyoxyethylene ether (Tween80) aqueous solution, 0.067wt% CaCl 2 Aqueous solution, 0.25wt%AgNO 3 The aqueous solution is ready for use.

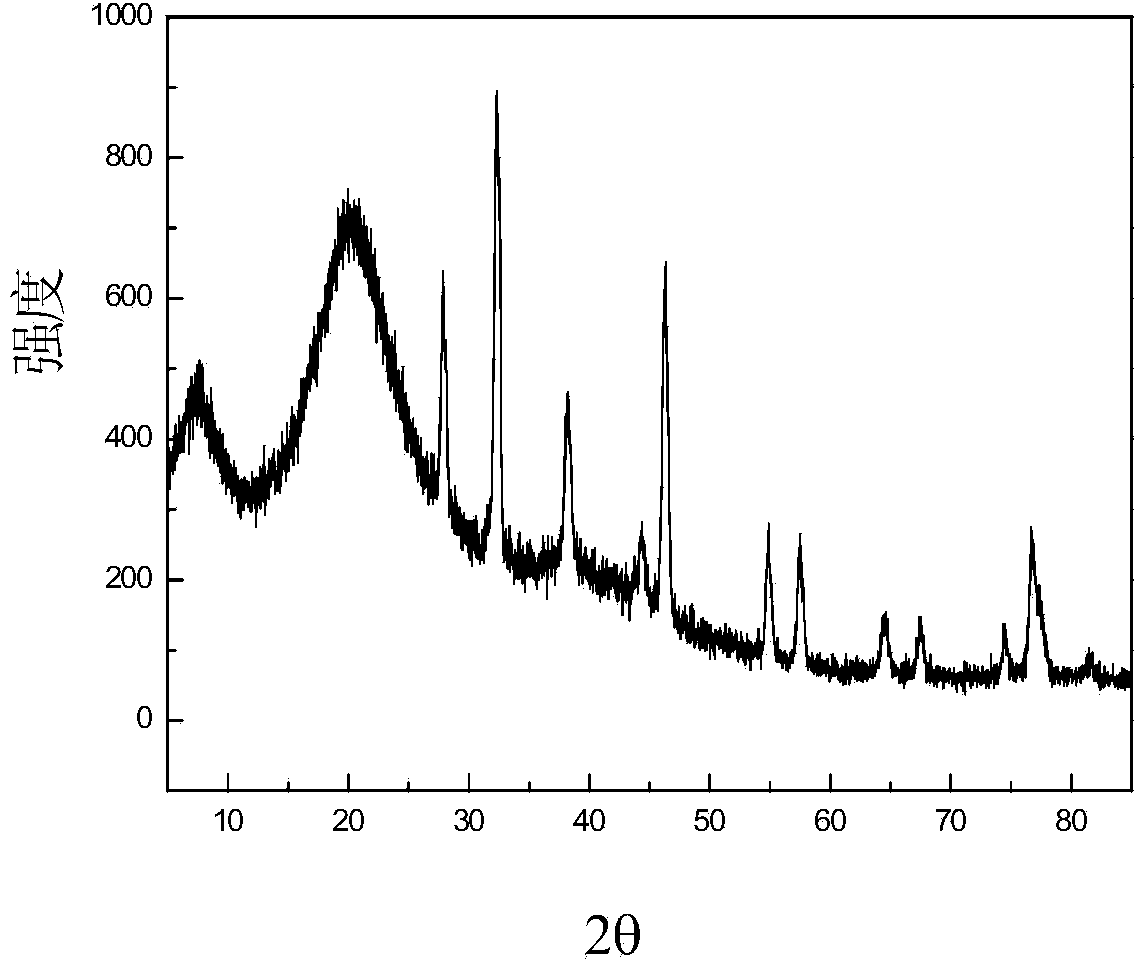

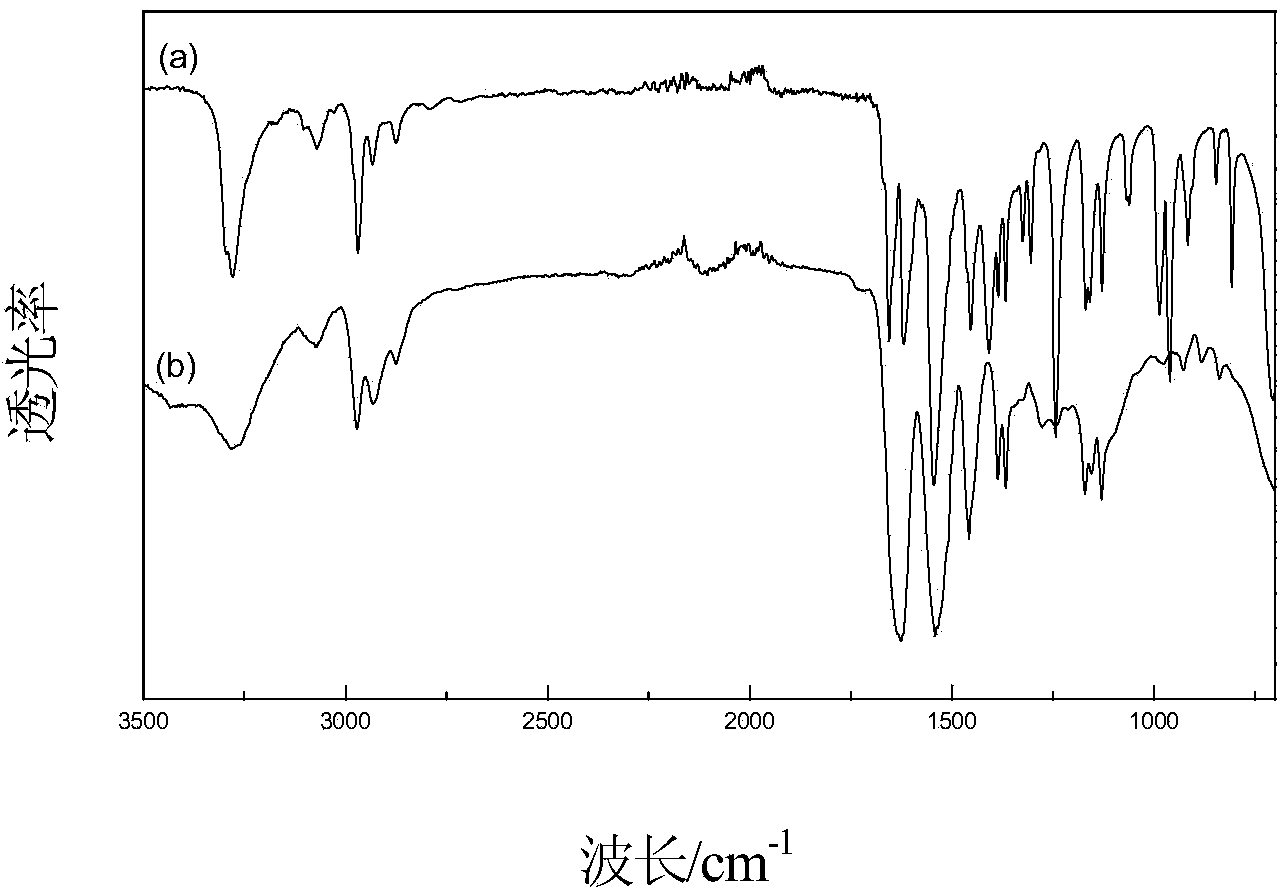

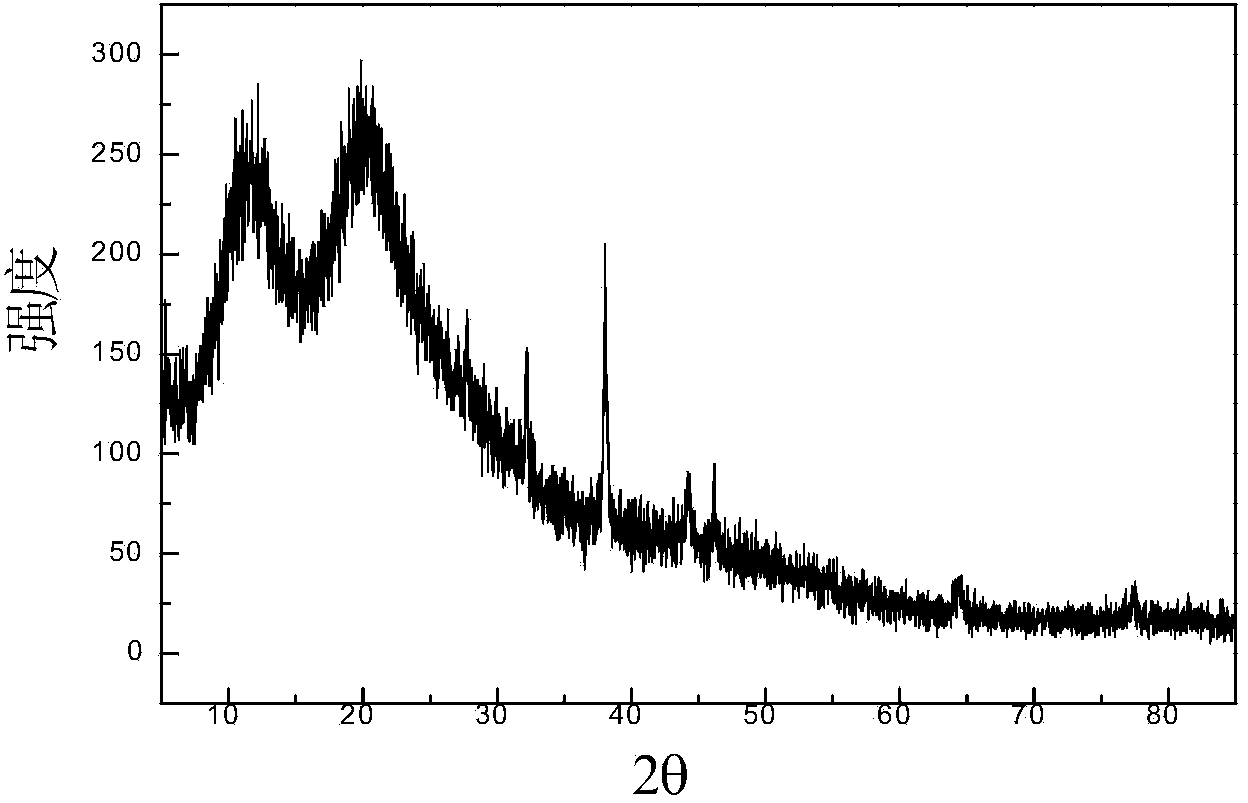

[0045] Take 20ml of Tween80 aqueous solution with a concentration of 1wt%, preheat it in a water bath at 50°C for 5min, add 20ml of CaCl with a concentration of 0.067wt% 2 The aqueous solution was stirred and reacted for 30min, and AgNO with a concentration of 0.25wt% was added rapidly 3 20 ml of aqueous solution was stirred in the dark for 30 minutes to obtain AgCl colloid, which was dialyzed with ultrapure water for 1.5 hours for later use. The particle size of active AgCl particles in the AgCl colloid was 50-800 nanometers. Weigh 0.7mmol of N-isopropylacrylamide and dissolve it in 1ml of deionized water, add 10ml of the above-prepared AgCl colloid, mix and stir evenly, and pass high-purity nitrogen gas N 2 Remove the air in the tube for 30 minutes, then seal the reaction tube, place it under a 36W ...

Embodiment 2

[0049] The same method as in Example 1, wherein N-isopropylacrylamide is replaced by N-isopropylmethacrylamide, the mass of which is 0.1g, to obtain poly-N-isopropylmethacrylamide, and the conversion rate is 100%.

Embodiment 3

[0051] With 1wt% Tween-80 aqueous solution, 0.067wt% CaCl 2 Aqueous solution, 0.25wt%AgNO 3 The aqueous solution is ready for use.

[0052] Take 20ml of Tween-80 aqueous solution with a concentration of 1wt%, preheat it in a water bath at 50°C for 5min, add 20ml of CaCl with a concentration of 0.067wt% 2 The aqueous solution was stirred and reacted for 30min, and AgNO with a concentration of 0.25wt% was added rapidly 3 20 ml of aqueous solution was stirred in the dark for 30 minutes to obtain AgCl colloid, which was dialyzed with ultrapure water for 2 hours for later use. The particle size of active AgCl particles in the AgCl colloid was 50-800 nm. Get the mixed solution 14mL (V 乙醇 :V AgCl胶体 =5:1), add 0.15g polyvinylpyrrolidone (PVP) as a dispersion stabilizer, magnetically stir until fully dissolved, then add 2mL styrene, magnetically stir to form an O / W transparent microemulsion, and introduce high-purity N 2 The air in the tube was removed for 30 minutes, and then the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com