A kind of polyoxymethylene composition and preparation method thereof

A polyoxymethylene composition and polyoxymethylene technology are applied in the field of materials, which can solve the influence of the density and shrinkage rate of the hollow glass microsphere material without mentioning the feeding method of the hollow glass microspheres, and the appearance quality of the shrinkage anisotropic injection molding products. , can not meet the problems of special applications, etc., to achieve the effect of environmental protection, beautiful color, small broken rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

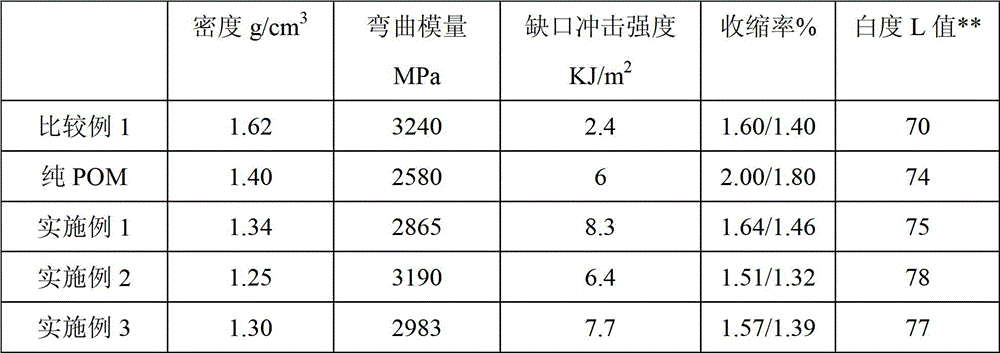

Examples

Embodiment 1

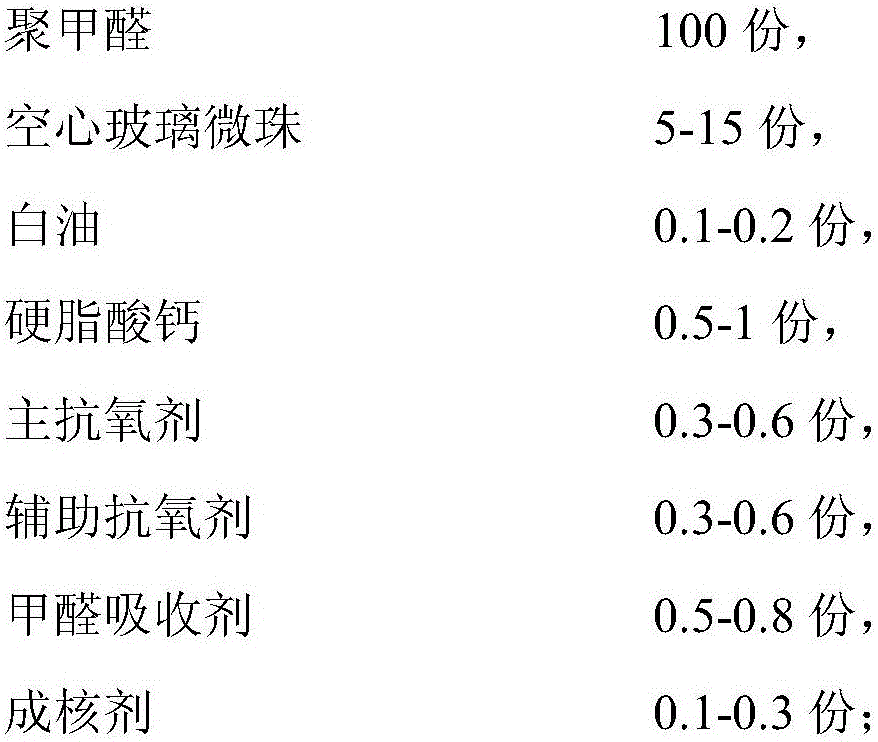

[0044] Firstly, the polyoxymethylene and hollow glass microbeads are respectively placed in a blast oven with a temperature range of 80-90℃ to dry for 3-4 hours.

[0045] (1) Add 100 parts by mass of polyoxymethylene (its melt index is 3g / 10min, and the measurement conditions are: 190℃, 2.16kg load), 0.2 parts of commercially available white oil is added to the high-speed mixer and mixed for 1-2min , Then add 0.5 part of calcium stearate, 0.4 part of antioxidant 245, 0.4 part of antioxidant 168, 0.5 part of melamine, and 0.1 part of zinc oxide into the high-speed mixer to mix, and mix well;

[0046] (2) Melt and blend the uniformly mixed raw materials in step (1) with a vented co-rotating twin-screw extruder. 5 parts of hollow glass microspheres are added to the extruder through side feeding, and then extruded and granulated. , The screw speed is 280 rpm, the barrel temperature (temperature / °C) is:

[0047] Hopper Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 Zone 7 Zone 8 Zone 9 Zone

...

Embodiment 2

[0051] First, the polyoxymethylene and hollow glass beads are placed in a blast oven with a temperature range of 80-90℃ to dry for 3-4 hours.

[0052] (1) Add 100 parts by mass of polyformaldehyde (its melt index is 12g / 10min, and the measurement conditions are: 190℃, 2.16kg load), and 0.1 part of commercially available white oil is added to the high-speed mixer and mixed for 1-2min , Then add 1 part of calcium stearate, 0.3 part of antioxidant 1010, 0.6 part of antioxidant 168, 0.8 part of melamine formaldehyde condensate, 0.3 part of light magnesium oxide into the high-speed mixer and mix well. well mixed;

[0053] (2) Melt and blend the uniformly mixed raw materials in step (1) with a vented co-rotating twin-screw extruder. 15 parts of hollow glass microspheres are added to the extruder through side feeding, and extruded and granulated. , The screw speed is 210 revolutions / minute, and the barrel temperature (temperature / °C) is:

[0054] Hopper Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 ...

Embodiment 3

[0058] Firstly, the polyoxymethylene and hollow glass microbeads are respectively placed in a blast oven with a temperature range of 80-90℃ to dry for 3-4 hours.

[0059] (1) Add 100 parts by mass of polyoxymethylene (its melt index is 18g / 10min, and the measurement conditions are: 190℃, 2.16kg load), 0.2 parts of commercially available white oil is added to the high-speed mixer and mixed for 1-2min , Then add 0.8 parts of calcium stearate, 0.3 parts of antioxidant 2246, 0.6 parts of antioxidant 168, 0.5 parts of melamine, and 0.2 parts of titanium dioxide into the high-speed mixer to mix, and mix well;

[0060] (2) Melt and blend the uniformly mixed raw materials in step (1) with a vented co-rotating twin-screw extruder. 10 parts of hollow glass microspheres are added to the extruder through side feeding, and extruded into granules. , The screw speed is 250 rpm, the barrel temperature (temperature / °C) is:

[0061] Hopper Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 Zone 7 Zone 8 Zone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com