Highlight low-volatile polybutylene terephthalate (PBT) composition as well as preparation method and application of composition

A polybutylene terephthalate and low-volatility technology, which is applied in the field of high-gloss and low-volatility polybutylene terephthalate composition and its preparation, can solve the problem of gas gas easily generated by PBT materials and the gloss of injection molded parts Insufficient brightness, affecting the mechanical properties of materials, etc., to achieve excellent mechanical and processing properties, less volatile matter, and improve gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~16 and comparative example 1~6

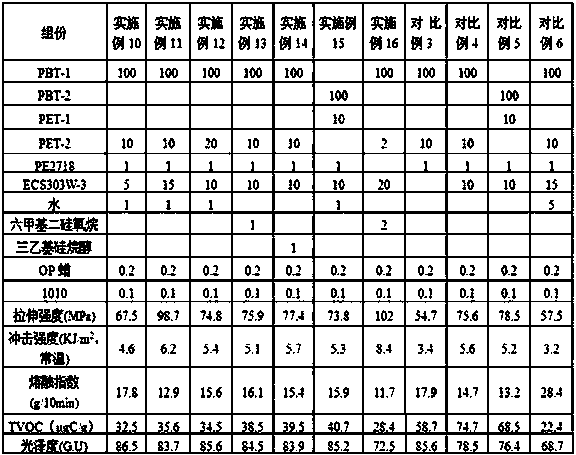

[0053] According to the proportions in Table 1~2, mix the dried PBT resin, PET resin, gloss additives, black seeds and additives in a high-speed mixer for 1-2 minutes to obtain a premix, and add the premix to the twin-screw extruder The extruder (screw diameter: 35mm, aspect ratio L / D=36) is melt-extruded, glass fiber is side-fed, and the finished product is made by two-stage vacuum granulation. Among them, the temperature of each screw barrel of the twin-screw extruder (from the feeding port to the machine head) is: 140°C, 220°C, 230°C, 240°C, 240°C, 220°C, the screw speed is 300 rpm, and the feeding amount 50kg / h. The product obtained above was dried in an oven at 120°C for 3-4 hours and then injected into a standard sample strip at a temperature of 250°C. The injection-molded standard strips were placed at 25°C and 50% relative humidity for 24 hours before testing performance. The performance test results are shown in Table 1-2.

[0054]

[0055] Table 1 High-gloss and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com