Special environment-friendly complete-synthesis cutting fluid for drilling stainless steel and preparation method thereof

A fully synthetic cutting fluid technology, which is applied in the preparation of fully synthetic cutting fluid, fully synthetic cutting fluid for stainless steel drilling, and fully synthetic cutting fluid for stainless steel drilling. and cooling performance, inhibition of bacterial growth, excellent fluidity and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

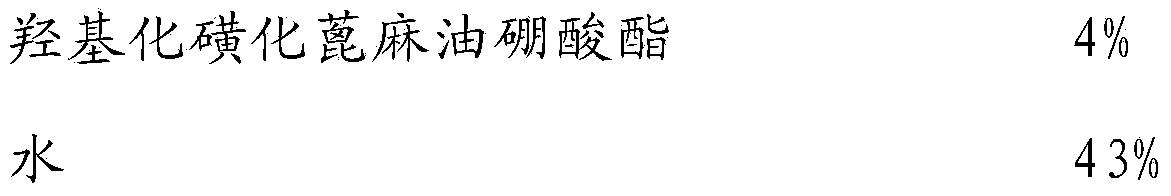

[0039]

[0040]Wherein, the diethylene glycol and stearic acid whose molar ratio of the extreme pressure lubricant is 1:1 are stirred and reacted at normal temperature and pressure until the solution is clear. Alcoholamine and sulfonated castor oil in the presence of alkali, according to the molar ratio of 5-7:1, using water as solvent, microwave heating, hydroxylation reaction at 130°C-150°C for 3-4h, slowly cooling down to about 80°C , react at constant temperature for 2-3 hours, further distill off glycerin and water under reduced pressure to obtain the intermediate product hydroxylated sulfonated castor oil; hydroxylated sulfonated castor oil and boric acid are esterified at 110-130 °C according to the molar ratio of 1:1.5-2 The reaction is 3-5h, and the hydroxylated sulfonated castor oil borate mixture is obtained.

[0041] According to the above material weight percentage, the preparation method of the cutting fluid is:

[0042] a) Hydroxylated sulfonated castor oil ...

Embodiment 2

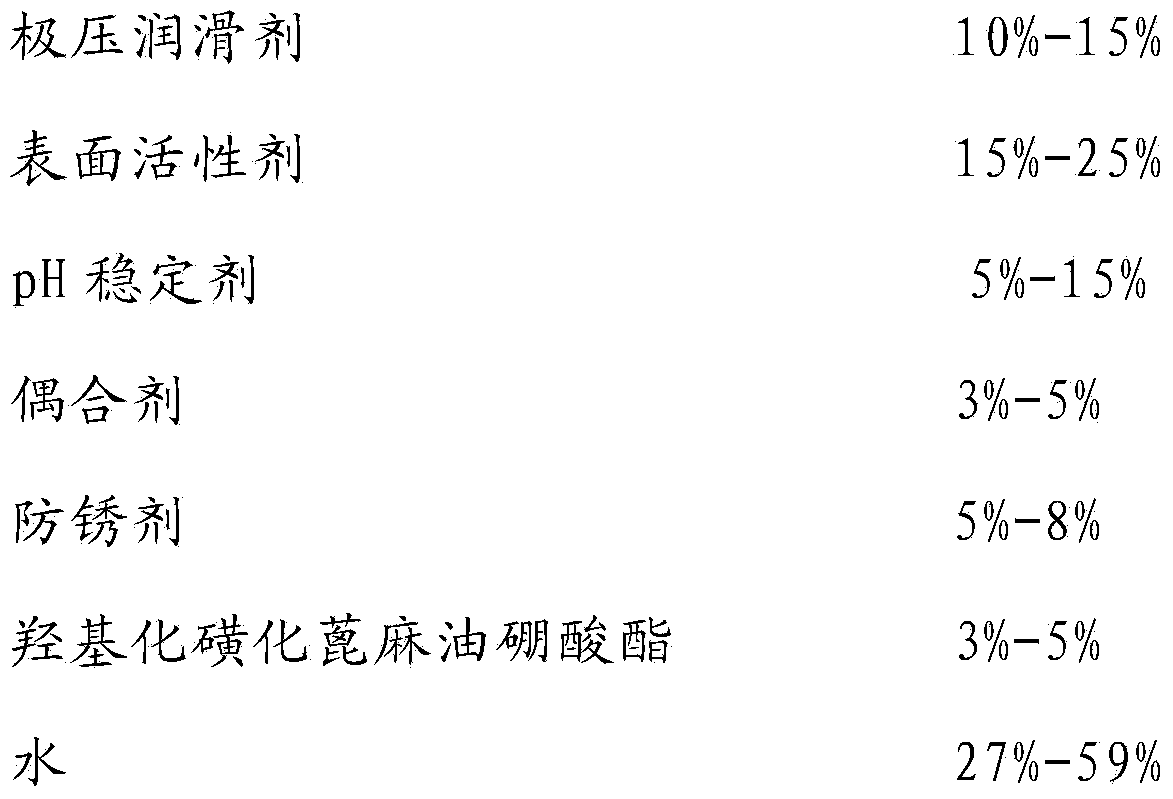

[0047]

[0048] Wherein, the molar ratio of the extreme pressure lubricant is oleic acid and cyclohexanol which are 3:1, stirred and reacted at normal temperature and pressure until the solution is clear. Alcoholamine and sulfonated castor oil in the presence of alkali, according to the molar ratio of 5-7:1, using water as solvent, microwave heating, hydroxylation reaction at 130°C-150°C for 3-4h, slowly cooling down to about 80°C , react at constant temperature for 2-3 hours, further distill off glycerin and water under reduced pressure to obtain the intermediate product hydroxylated sulfonated castor oil; hydroxylated sulfonated castor oil and boric acid are esterified at 110-130 °C according to the molar ratio of 1:1.5-2 The reaction is 3-5h, and the hydroxylated sulfonated castor oil borate mixture is obtained.

[0049] According to the above material weight percentage, the preparation method of the cutting fluid is:

[0050] a) Hydroxylated sulfonated castor oil borat...

Embodiment 3

[0055]

[0056]

[0057] Wherein, the molar ratio of the extreme pressure lubricant is ricinoleic acid and octanol of 4:1, which is stirred and reacted at normal temperature and pressure until the solution is clear. Alcoholamine and sulfonated castor oil in the presence of alkali, according to the molar ratio of 5-7:1, using water as solvent, microwave heating, hydroxylation reaction at 130°C-150°C for 3-4h, slowly cooling down to about 80°C , react at constant temperature for 2-3 hours, further distill off glycerin and water under reduced pressure to obtain the intermediate product hydroxylated sulfonated castor oil; hydroxylated sulfonated castor oil and boric acid are esterified at 110-130 °C according to the molar ratio of 1:1.5-2 The reaction is 3-5h, and the hydroxylated sulfonated castor oil borate mixture is obtained.

[0058] According to the above material weight percentage, the preparation method of the cutting fluid is:

[0059] a) Hydroxylated sulfonated ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com