Stator permanent magnet mixed stepping motor

A technology of stepping motors and permanent magnets, applied in the direction of electromechanical devices, electrical components, magnetic circuit rotating parts, etc., can solve the uneven distribution of air gap permanent magnet flux density along the axial direction, increase the amount of permanent magnets, and increase the torque Problems such as low density and efficiency power level, to achieve uniform distribution of air-gap permanent magnet flux density, reduce processing and manufacturing difficulty, and simplify analysis and design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

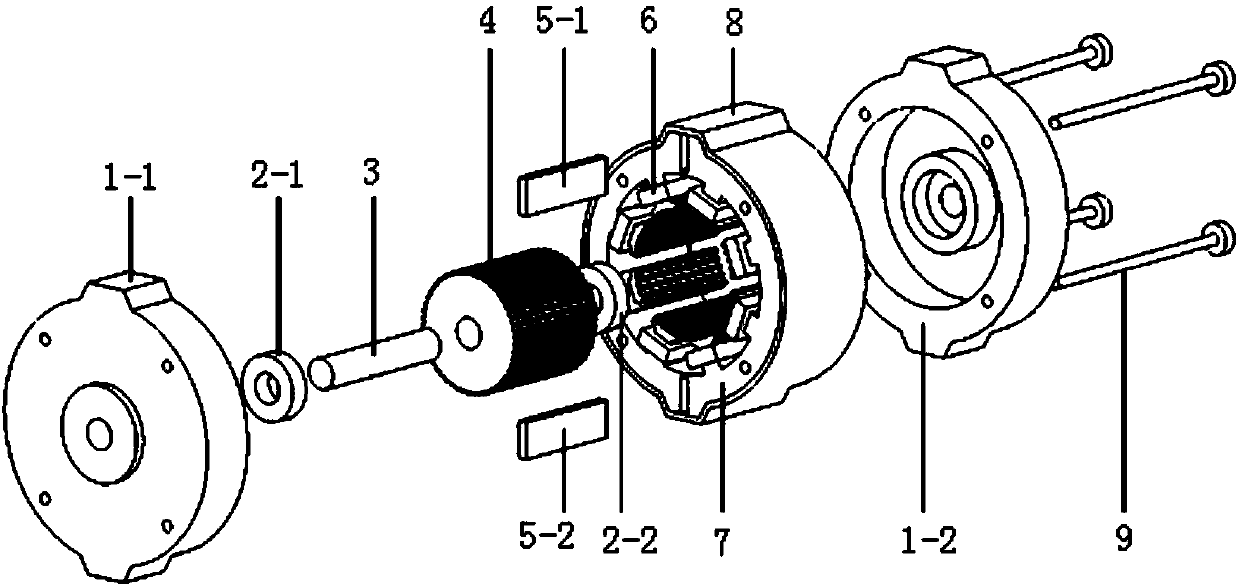

[0062] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

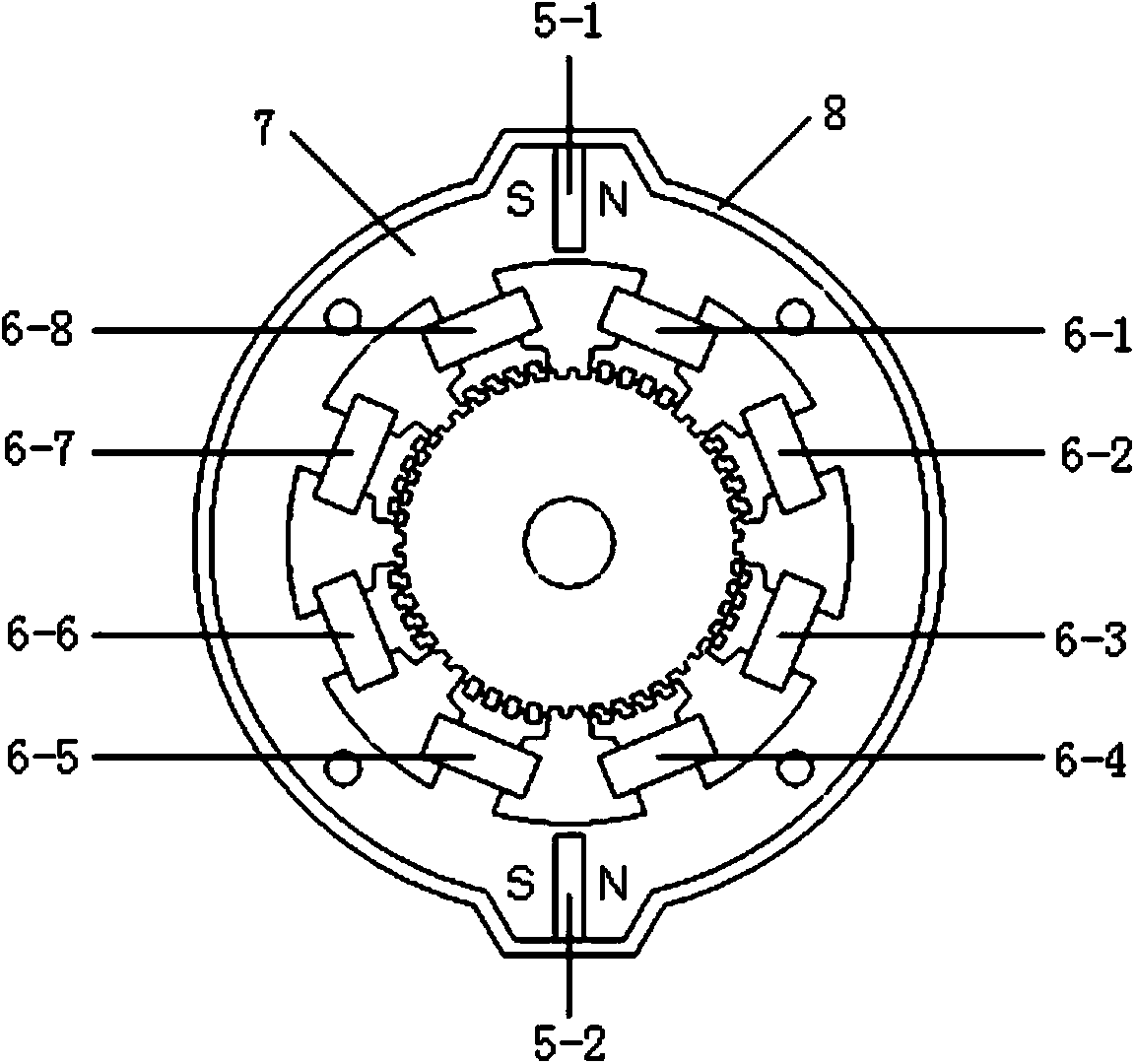

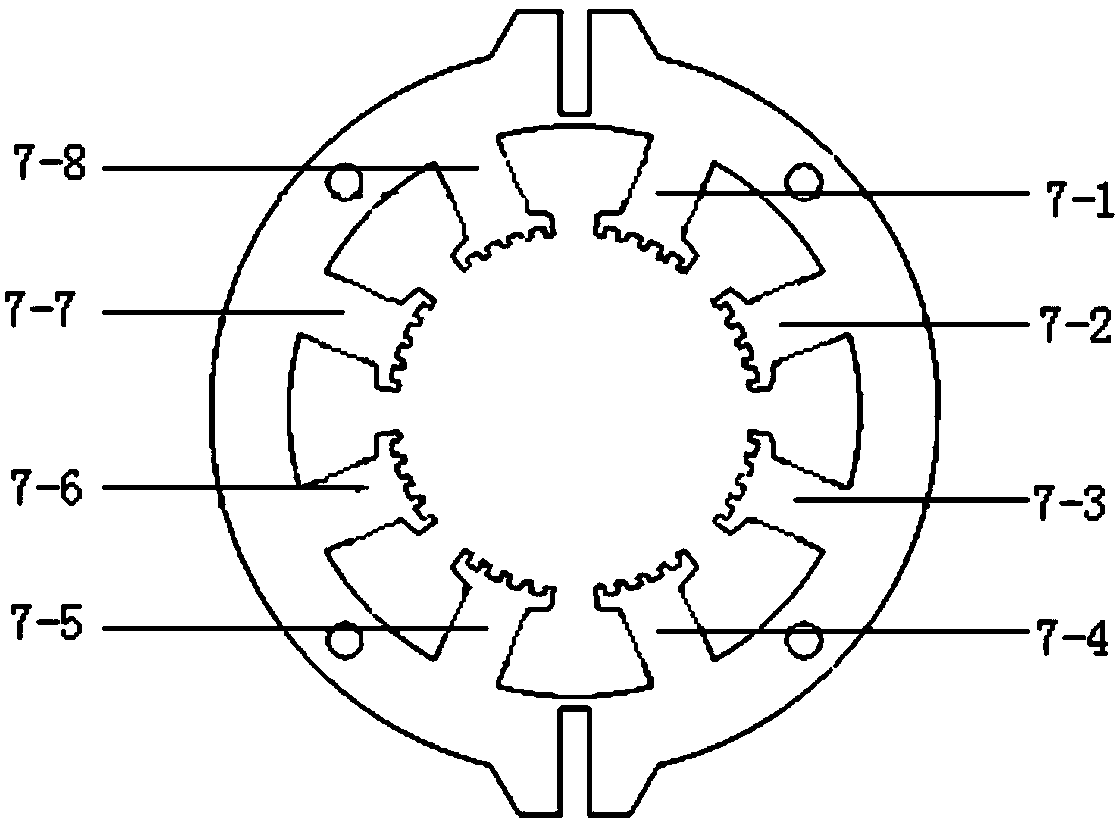

[0063] A stator permanent magnet hybrid excitation stepping motor includes a stator part and a rotor part. The rotor part includes the rotor core 4 and the rotating shaft 3 arranged inside the core. The rotor laminated core has only one section, and the same small teeth are evenly distributed on its circumference; the stator part includes the stator core 7, the stator winding 6 and the stator permanent magnet 5. The stator The same magnetic poles are distributed on the inner circumference of the iron core 7, and the stator teeth with the same pitch as the small teeth on the surface of the rotor are distributed on the pole shoes of each magnetic pole. Coils are placed on the pole body of each magnetic pole, and the coils are connected in series or parallel to form a motor. In the multi-phase winding of the stator core, permanent magnets 5 magnetized alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com