Au@Rh nano particle supported catalyst with core-shell structure and preparation method of Au@Rh nano particle supported catalyst

A nanoparticle and catalyst technology, applied in the field of nanocatalysts, achieves the effects of uniform particle size, cost reduction, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Preparation of Gold Nanospheres

[0027] 1.5ml 0.01M HAuCl 4 Add the aqueous solution to 30ml of 0.1M sodium citrate aqueous solution, adjust the total volume of the solution to 61.5ml, and mix well. Add 1.8ml of 0.1M NaBH cooled in an ice-water bath at one time 4 Aqueous solution, the solution immediately turns pink, stirred in a water bath at 25°C for 2-4 hours. Add 4.5ml of 0.01M HAuCl4 aqueous solution to 144ml of 0.1M CTAB aqueous solution, adjust the total volume of the solution to 180ml, add 1.2ml of 0.1M freshly prepared ascorbic acid aqueous solution, mix well, the solution becomes colorless, add the above gold seed solution, After stirring in a water bath at 25°C for 10 min, the solution changed from colorless to wine red.

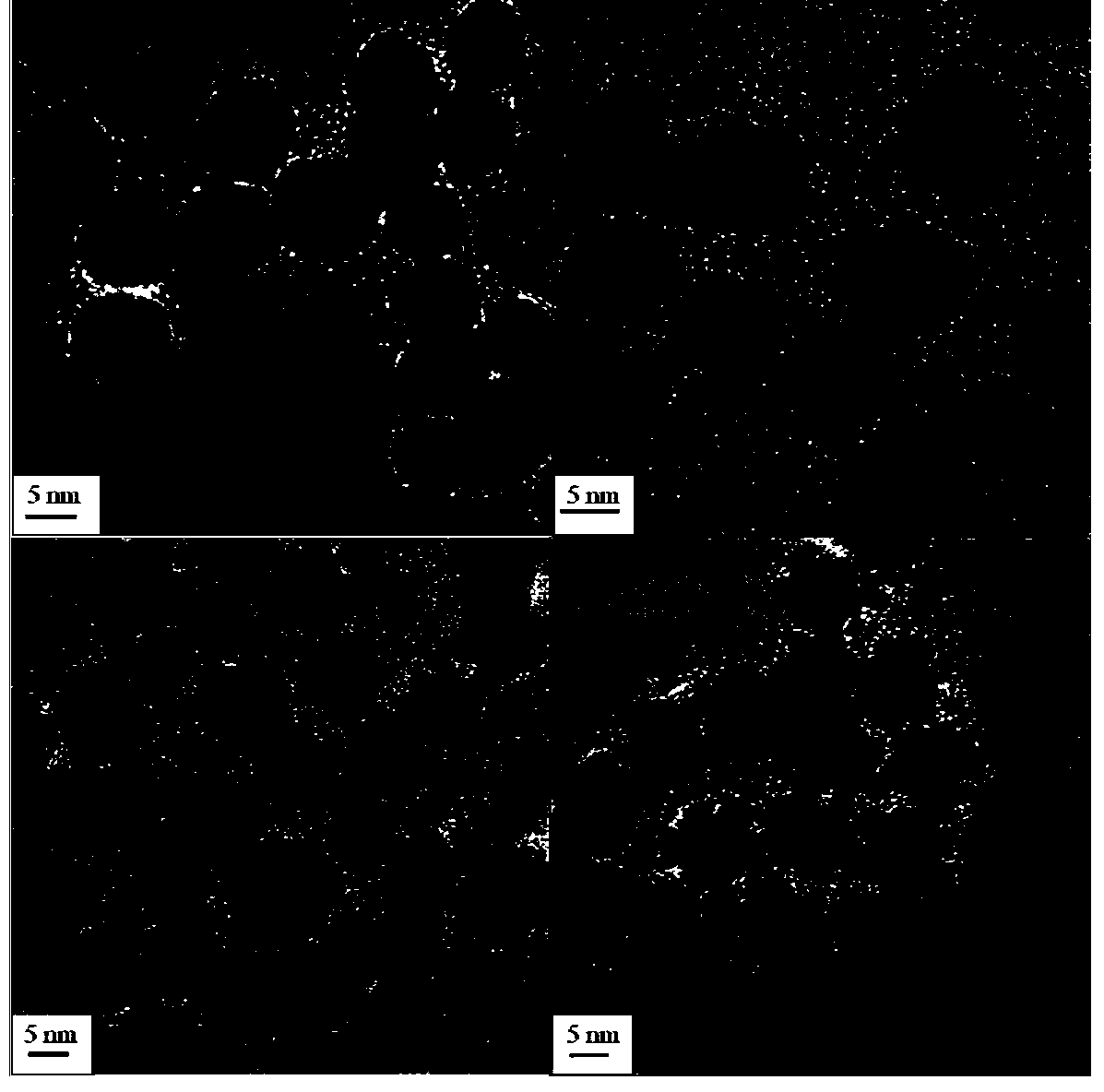

[0028] 2. Preparation of AuRh nanoparticles

[0029] Centrifuge the above gold nanosphere solution at 24000r / h for 30min, remove the supernatant, redisperse in 5ml of high-purity water, and add 6ml of 0.002M RhCl in turn 3Aqueous s...

Embodiment 2

[0033] 1. Preparation of Gold Nanospheres

[0034] Ditto.

[0035] 2. Preparation of AuRh nanoparticles

[0036] Centrifuge the above gold nanosphere solution at 24000r / h for 30min, remove the supernatant, redisperse in 5ml of high-purity water, add 15ml of 0.002M RhCl 3 Aqueous solution, 50ml0.1M CTAB aqueous solution, 20ml0.2M freshly prepared ascorbic acid aqueous solution, adjust the total volume of the solution to be 90ml, the mixed solution of gold nanospheres, water-soluble Rh salt, protective agent, and newly prepared reducing agent in the solution The molar ratio in the solution was 2:1:5:4, stirred in an oil bath at 140°C for 40 minutes, the solution changed from wine red to brownish black, and AuRh nanoparticles with a molar ratio of Au:Rh of 2:1 were obtained.

[0037] 3. AuRh / γ-Al 2 o 3 Catalyst preparation

[0038] Centrifuge the above AuRh nanoparticle solution at 24000r / h for 30min, remove the supernatant, redisperse in 10ml of high-purity water, ultrasoni...

Embodiment 3

[0040] 1. Preparation of Gold Nanospheres

[0041] Ditto.

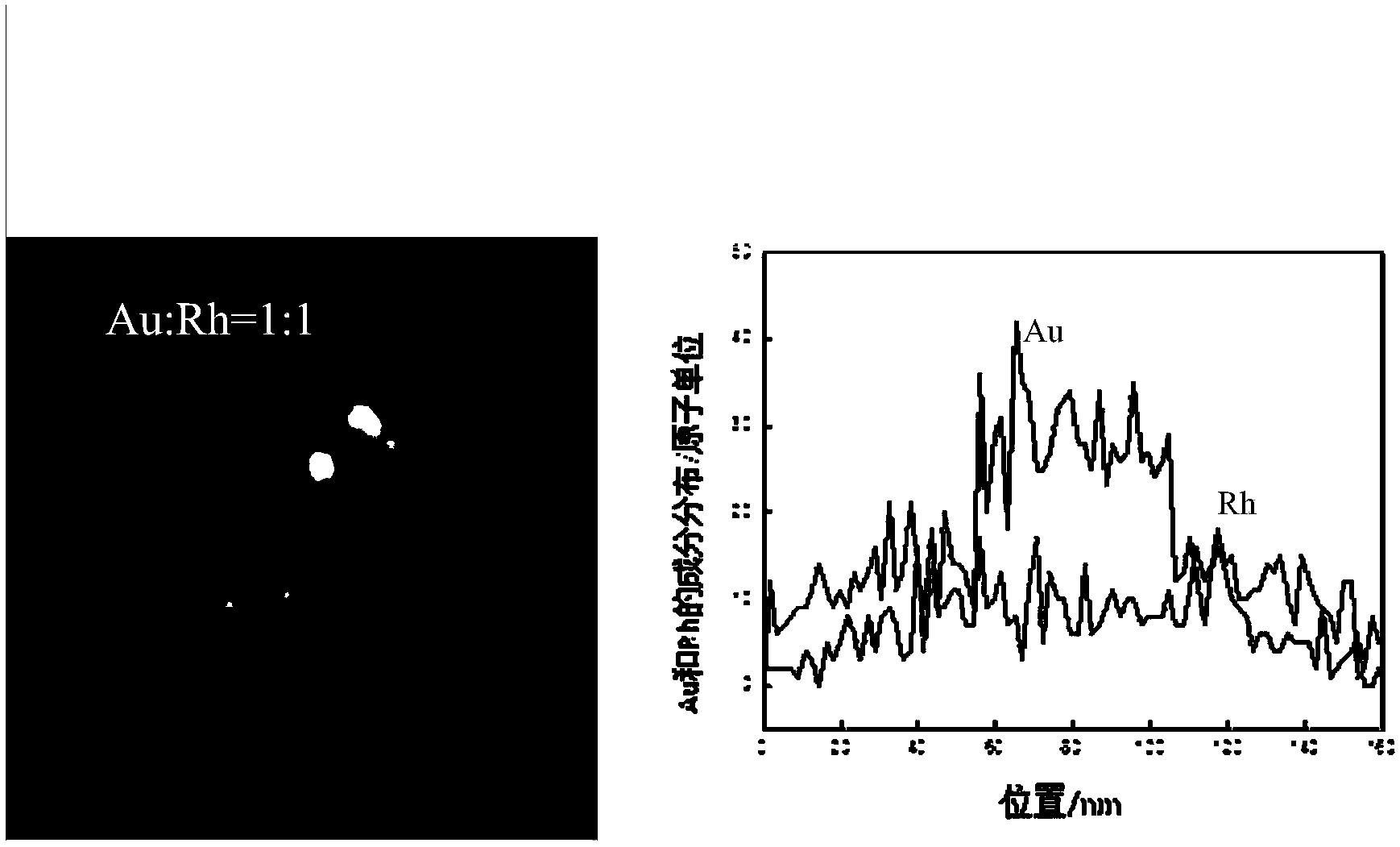

[0042] 2. Preparation of AuRh nanoparticles

[0043] Centrifuge the above gold nanosphere solution at 24000r / h for 30min, remove the supernatant, redisperse in 5ml of high-purity water, add 30ml of 0.002M RhCl in turn 3 Aqueous solution, 35ml of 0.1M CTAB aqueous solution, 20ml of 0.2M freshly prepared ascorbic acid aqueous solution, adjusting the total volume of the solution to 90ml, the mixed solution of gold nanospheres, water-soluble Rh salt, protective agent, and newly prepared reducing agent in the solution The molar ratio in the solution was 1:1:3.5:4. Stirred in an oil bath at 140°C for 40 minutes, the solution changed from wine red to brownish black, and AuRh nanoparticles with a molar ratio of Au:Rh of 1:1 were obtained.

[0044] 3. AuRh / γ-Al 2 o 3 Catalyst preparation

[0045] Centrifuge the above AuRh nanoparticle solution at 24000r / h for 30min, remove the supernatant, redisperse in 10ml of high-purit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com