Back elevation clamp of initial die

A technology of back-to-face and initial mold, applied in the field of mold fixtures, can solve the problems of troublesome replacement of parts, inability to self-center the outer circle, unstable parts size, etc., to save working time, improve the processing qualification rate, The effect of ensuring the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

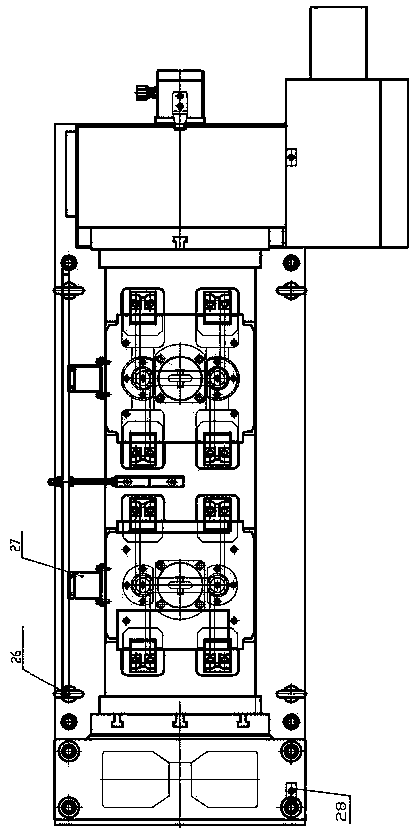

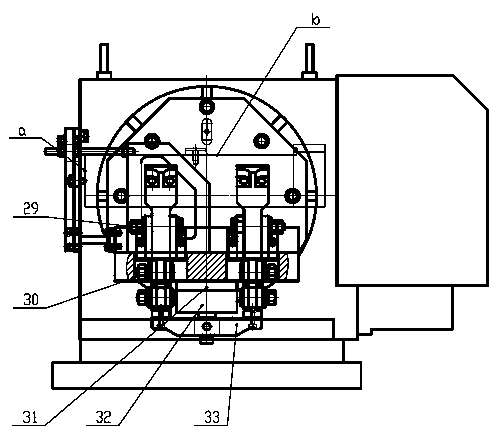

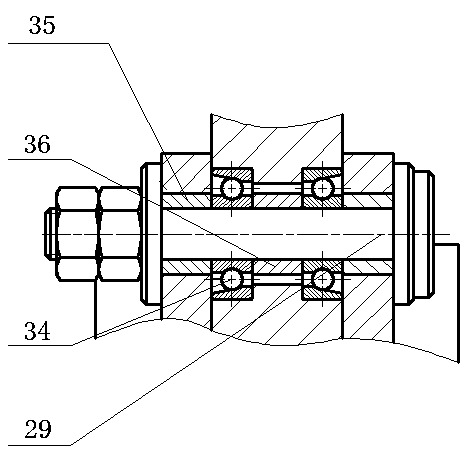

[0019] Such as Figure 1 to Figure 4 Shown are respectively the front view, top view, left view, and partial cross-sectional schematic diagrams of the back elevation fixture of the blank mold of the present invention after the parts are installed.

[0020] A fixture for the back and elevation of a blank forming mold, including a turntable tail frame bridge structure, a self-centering positioning clamping mechanism, and a lateral positioning mechanism; wherein the mother board of the turntable tail frame bridge structure is equipped with two sets of self-centering positioning Clamping mechanism, self-centering positioning A lateral positioning mechanism is arranged in front of the clamping mechanism.

[0021] The turntable tailstock bridge structure includes: base plate 1, tailstock spacer 2, motherboard 3, mandrel 4, tailstock 5, tailstock connection plate 6, key A 7, turntable connection plate 21, oil distribution mechanism 22, turntable 23. Turntable block 24, key B 25, lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com