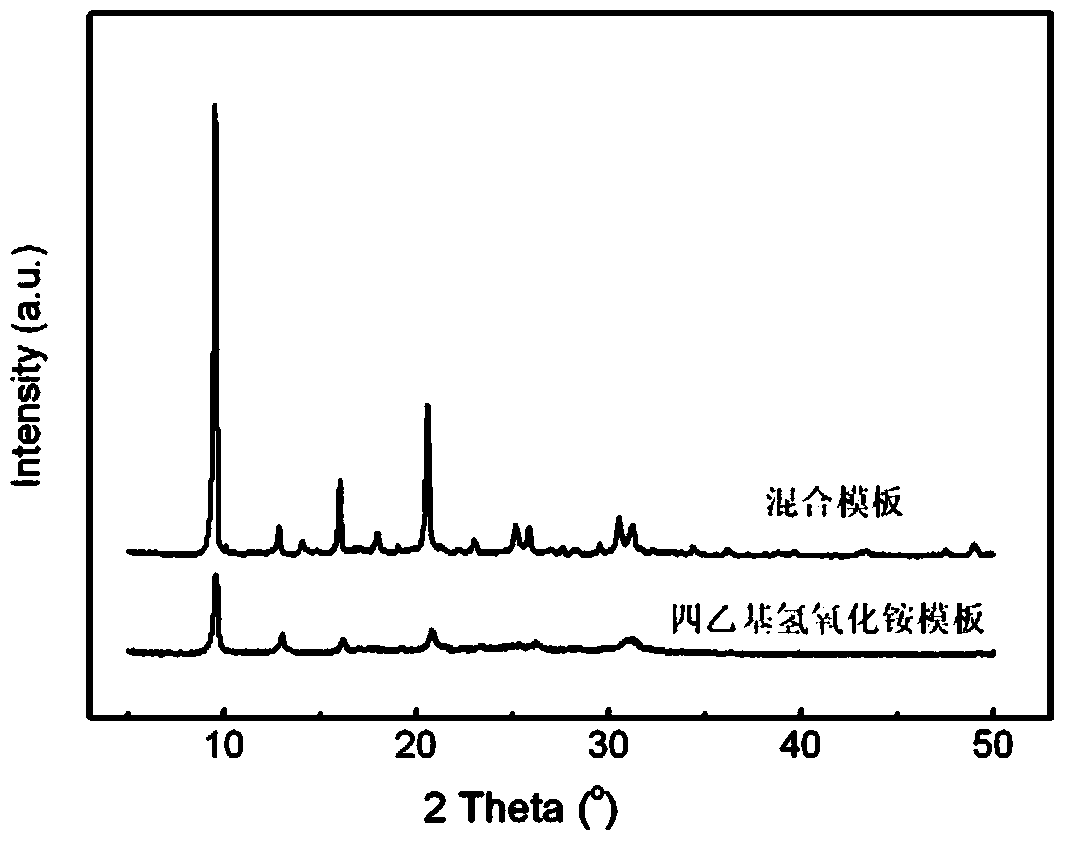

Method for synthesizing SAPO-34 molecular sieve with high crystallinity

A SAPO-34, high crystallinity technology, applied in molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of low cost, long crystallization time, low molecular sieve crystallinity, etc., to achieve the required The effect of short time, low cost, excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1, (1) Mixing: first fully stir 1 mol of pseudo-boehmite in 50 mol of deionized water, then slowly add 0.9 mol of phosphoric acid with a mass concentration of 84% to completely peptize the pseudo-boehmite; After completion, add 0.6mol 40wt.% silica sol and stir evenly, then add 2mol tetraethylammonium hydroxide and 0.5mol diethylenetriamine auxiliary templating agent, and stir vigorously;

[0019] (2) Crystallization: After stirring for 4 hours, put it into a stainless steel reaction kettle lined with tetrafluoroethylene or p-polystyrene; put the reaction kettle at 190 o C crystallized for 2 days;

[0020] (3) Drying and roasting: After the crystallization is completed, the obtained product is centrifuged and washed 5 times, and the obtained solid product is dried in an oven at 90°C for 4 hours; then the dried product is heated to 550°C at 5°C / min and roasted for 6 hours to obtain The product is a high crystallinity SAPO-34 molecular sieve synthesized rapidly. ...

Embodiment 2

[0023] Example 2, (1) Mixing: First, fully stir 1 mol of pseudo-boehmite in 60 mol of deionized water, then slowly add 0.9 mol of phosphoric acid with a mass concentration of 86% to completely peptize the pseudo-boehmite; After completion, add 0.5mol 40wt.% silica sol and stir evenly, then add 2.5mol triethylamine and 0.4mol diethylenetriamine mixed tablet and stir vigorously;

[0024] (2) Crystallization: Stir the mixed solution in step (1) for 5 hours and put it into a stainless steel reactor lined with tetrafluoroethylene or p-polystyrene; crystallize the reactor at 195°C for 1.5 days;

[0025] (3) Drying and roasting: After the crystallization is completed, the obtained product is centrifuged and washed 5 times, and the obtained solid product is dried in an oven at 90°C for 4 hours; then the dried product is heated to 550°C at 3°C / min and roasted for 6 hours to obtain The product is a high crystallinity SAPO-34 molecular sieve synthesized rapidly.

[0026] figure 2 The...

Embodiment 3

[0027] Example 3, (1) Mixing: First, fully stir 1 mol of pseudo-boehmite in 50 mol of deionized water, then slowly add 0.9 mol of phosphoric acid with a mass concentration of 85% to completely peptize the pseudo-boehmite; After completion, add 0.6mol fumed silicon and stir evenly, then add 2mol tetraethylammonium hydroxide and 0.5mol diethylenetriamine auxiliary templating agent and stir vigorously;

[0028] (2) Crystallization: Stir the mixed solution in step (1) for 4 hours and put it into a stainless steel reactor lined with tetrafluoroethylene or p-polystyrene; crystallize the reactor at 190 °C for 2 days;

[0029] (3) Drying and roasting: After the crystallization is completed, the obtained product is centrifuged and washed 5 times, and the obtained solid product is dried in an oven at 90°C for 4 hours; then the dried product is heated to 650°C at 0.5°C / min and roasted for 3 hours to obtain The product is a high crystallinity SAPO-34 molecular sieve synthesized rapidly. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com