Color electrophoretic coating process of aluminum alloy sections

An aluminum alloy profile, color electrophoresis technology, applied in electrophoretic coatings, electrolytic coatings, electrophoretic plating, etc., can solve the problems of complex process, large environmental pollution, and the appearance color of the paint film is not stable enough, and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

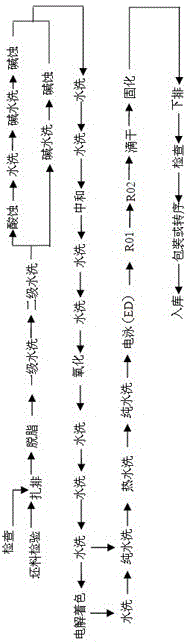

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with drawings and embodiments.

[0034] Such as figure 1 As shown, a color electrophoretic painting process for aluminum alloy profiles, the process mainly includes the steps of blank preparation and binding, degreasing, acid etching, alkali etching, neutralization, oxidation, electrolytic coloring, water washing, electrophoresis, curing, etc. Specific steps are as follows:

[0035] (1) Blank preparation and arrangement

[0036] Put the new aluminum wire or the aluminum wire for secondary use in the alkali tank, after alkali etching, wash it in two stages, after neutralization, wash it in two stages, dry it, and then tie it up;

[0037] (2) Degreasing

[0038] Put the assembled profiles into the degreasing tank with an inclination of more than 25 degrees, keep the profiles in the degreasing tank for 2 to 4 minutes, put out the post-control liquid for 30 seconds, and then perform two-stage water wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com