Ion beam etching depth monitoring method

A technology of ion beam etching and etching depth, which is applied in semiconductor/solid-state device testing/measurement, electrical components, circuits, etc. It can solve problems such as large differences in judgment results, difficulty in maintaining constant values, and poor stability , to achieve the effect of low price, low cost and simple experimental method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

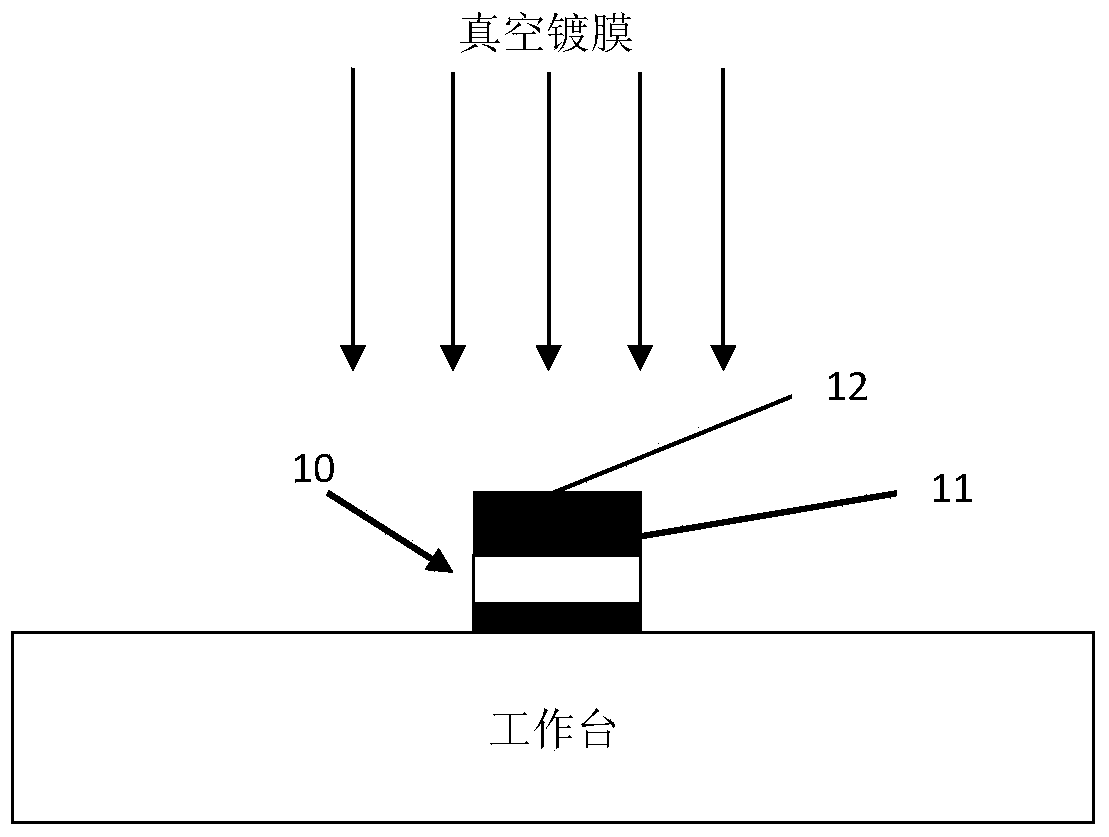

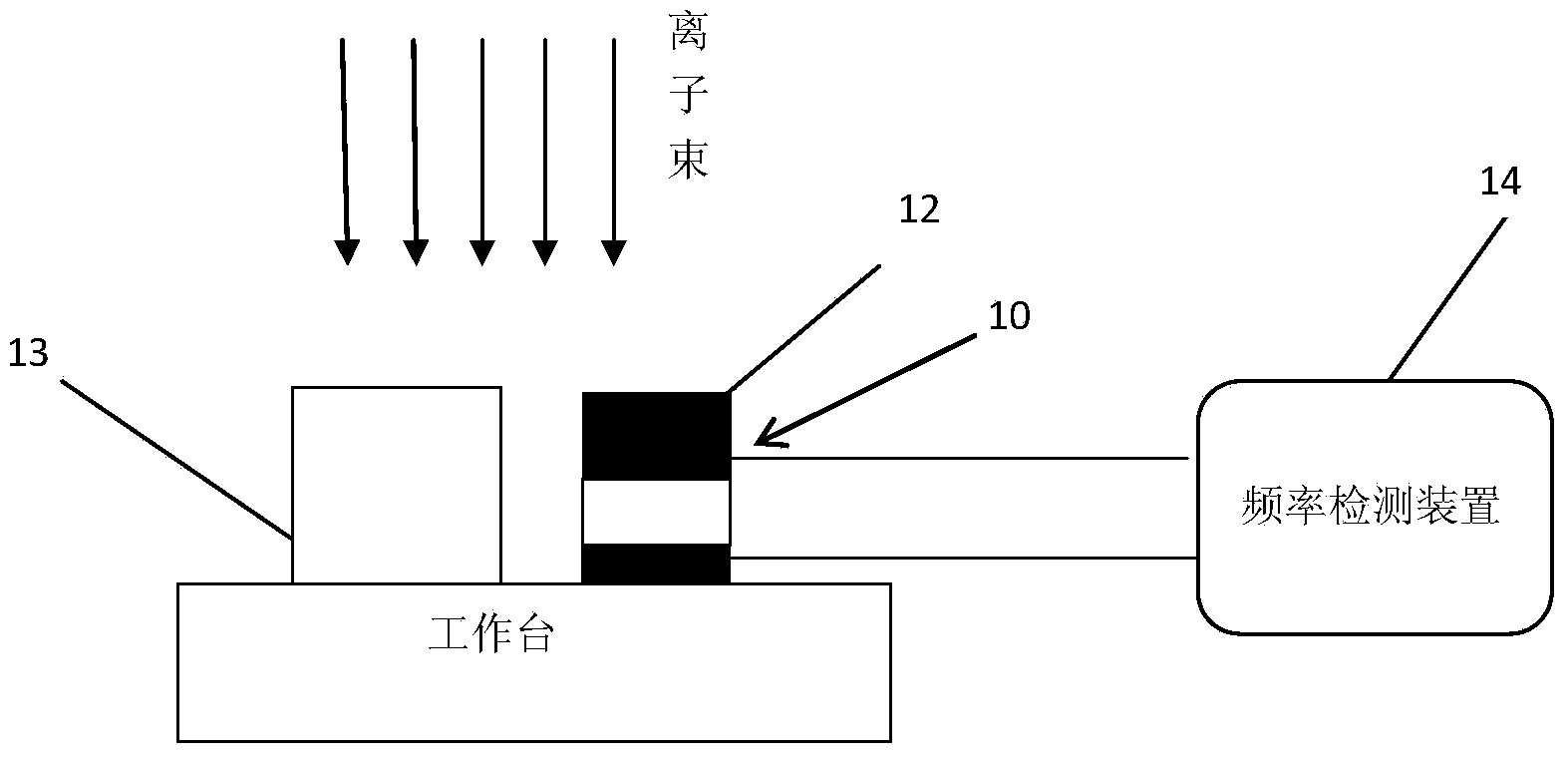

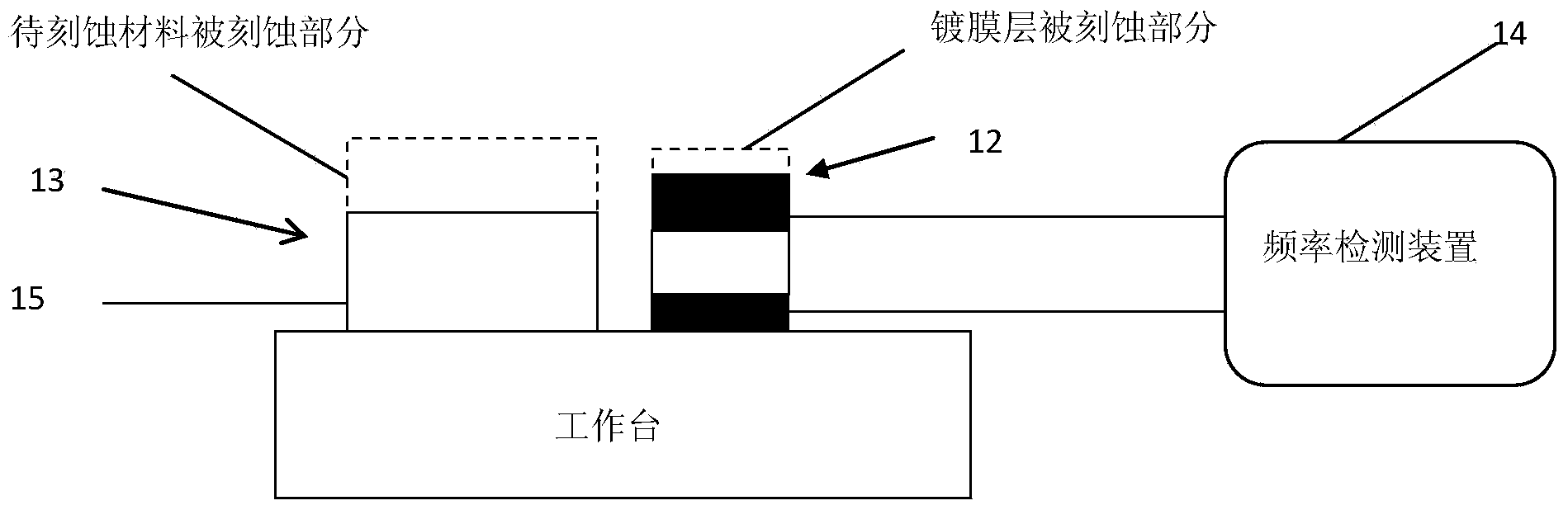

[0023] The method for monitoring the ion beam etching depth involved in the present invention will be further described below in conjunction with the accompanying drawings.

[0024]

[0025] In this embodiment, energy 500ev, beam current density 1mA / cm 2 For etching under the experimental conditions of vertical incidence, the material to be etched is a silicon wafer, the standard material is an aluminum film, and the target etching depth of the silicon wafer is 190nm.

[0026] The silicon wafer and the aluminum film were respectively subjected to ion beam etching experiments under the above experimental conditions to obtain the etching rate of the aluminum film and the silicon wafer, so that the ratio of the etching rate of the aluminum film to the silicon wafer was 1.29:1.

[0027] According to the etching rate ratio of the two and the target etching depth of the silicon wafer, through calculation, the predetermined etching depth of the aluminum film is 245nm, and the prede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com