Aluminum resin bonded body and method for producing same

A manufacturing method, technology of aluminum resin, used in chemical instruments and methods, coatings, layered products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

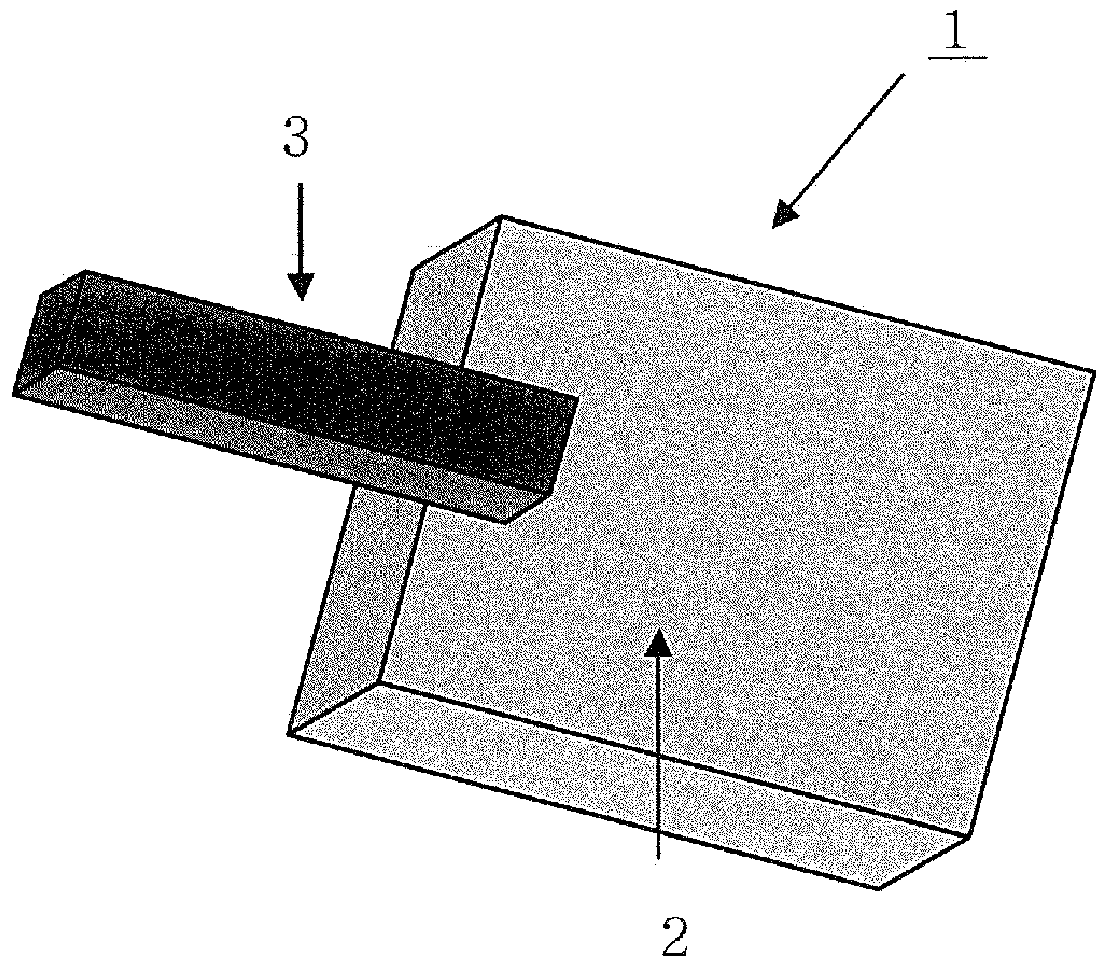

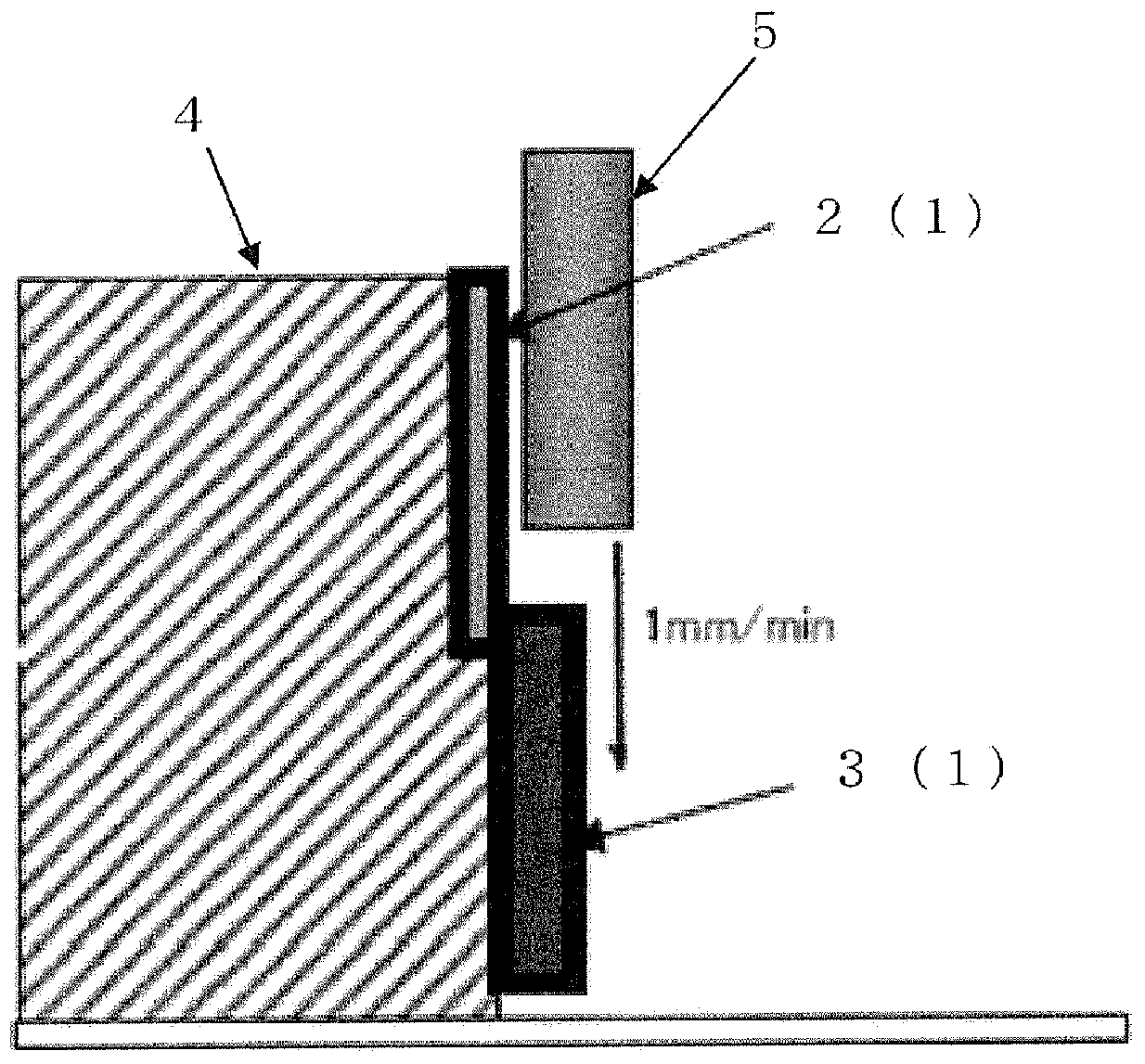

[0060] (1) Manufacture of surface-treated aluminum substrates

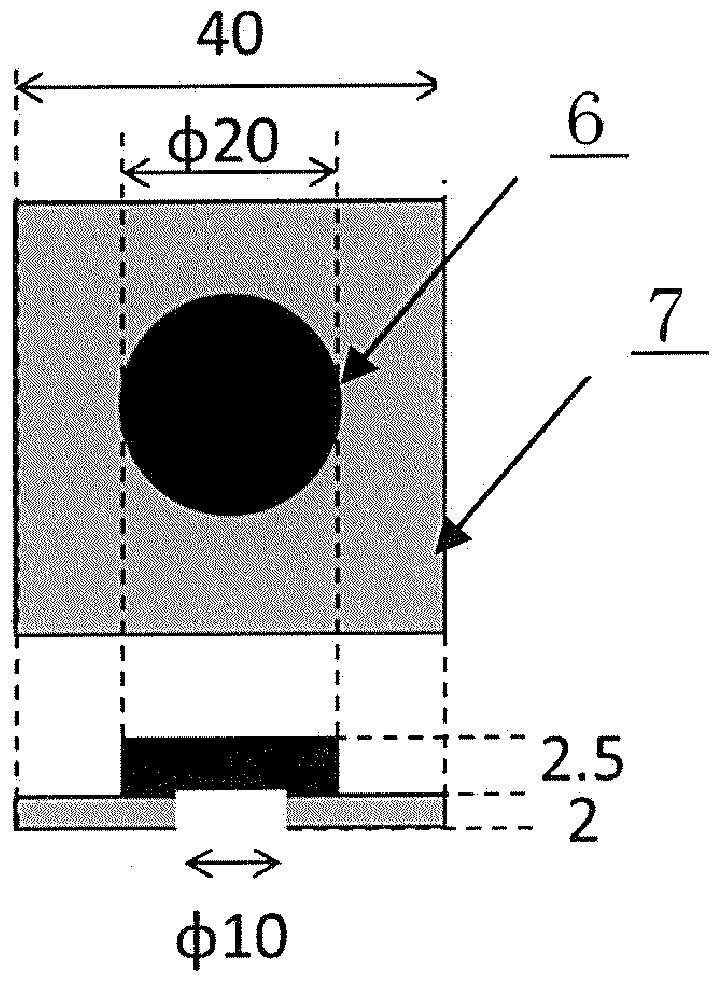

[0061] An aluminum substrate for a joint strength test of a size of 40 mm×40 mm was cut out from a commercially available aluminum plate material (A5052; plate thickness 2.0 mm). Next, a hole of 10 mmφ was made in the center of the aluminum substrate cut into a size of 40 mm×40 mm to prepare an aluminum substrate for an airtightness test. In addition, the concentration of sodium hydroxide 100g / L and the concentration of zinc oxide 25g / L (in terms of Zn + 20g / L) sodium aqueous solution containing zinc ions. Next, the above-mentioned aluminum substrate was immersed in the sodium aqueous solution containing zinc ions at room temperature for 3 minutes, and then washed with water to prepare a surface-treated aluminum substrate for testing in which an oxygen-containing film containing zinc was formed on the surface. .

[0062] (2) Determination of the oxygen content of the film

[0063] The obtained surface-treated ...

Embodiment 2~9

[0078] In addition to using the aluminum substrate of the material shown in Table 1 for the aluminum substrate, the alkaline aqueous solution containing zinc ions uses the solution composed of the solution shown in Table 1, and the concentration of the alkali hydroxide and the concentration of zinc ions are changed to the concentrations shown in Table 1. Except that, an aluminum resin bonded body for a test was produced in the same manner as in Example 1, and IR analysis of the resin portion, and evaluation tests for bonding strength and airtightness were performed in the same manner as in Example 1.

[0079] The results are shown in Table 1.

Embodiment 10~11

[0081] The aluminum substrates were made of the materials shown in Table 1, and were immersed in a 30 wt% nitric acid aqueous solution at room temperature for 5 minutes, then thoroughly washed with ion-exchanged water, and then immersed in a 5 wt% sodium hydroxide solution at 50°C for 1 After 10 minutes, wash with water, and then soak in 30wt% nitric acid aqueous solution at room temperature for 3 minutes before washing with water. Next, an aluminum film formation treatment was performed by immersing in hot water at 80° C. for 20 minutes for hydration treatment to form an oxygen-containing film containing aluminum compound AlO(OH) on the surface of the aluminum substrate. 1 An aluminum resin bonded body for testing was manufactured in the same manner as in Example 1, and the IR analysis of the resin portion, and the evaluation tests for bonding strength and airtightness were performed in the same manner as in Example 1.

[0082] The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com