Enzyme for conditioning spleen and stomach damp-heat constitution and preparation method thereof

A technology for damp-heat constitution and conditioning the spleen and stomach, which can be used in food preparation, pharmaceutical formulations, medical preparations containing active ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Material ratio: 10% almond, 10% black sesame, 15% coix seed, 15% pea, 15% kidney bean, 3% capillary, 3% chrysanthemum, 10% wax gourd, 10% chayote, 3% Alisma, wolfberry 3%, licorice 3%;

[0040] Probiotics: Monascus, Rhodotorula viscosus, Bacteroides albicans, Brettanomyces, Streptomyces agglomerans, Streptomyces nigerogenes, Kluyveromyces lactis, and Streptococcus lactis.

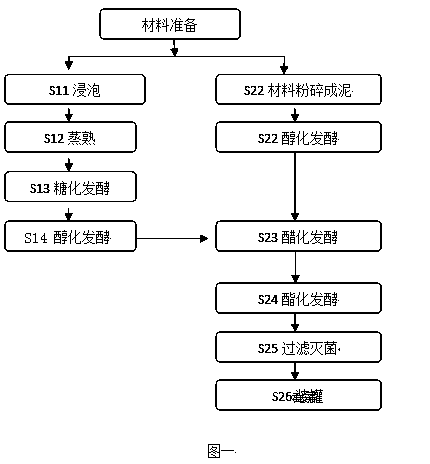

[0041] Process flow of the present invention:

[0042] (S11), soak almonds, black sesame, and coix seed in water at 75°C for 4 hours;

[0043] (S12), after the step S11) is completed, steam them in a steamer for 90 minutes, and then use a water bath at 25°C. After the materials are cooled, cover them with gauze to keep them moist;

[0044] (S13), put the material after step S12) into the fermentation tank, add Monascus and Rhodotorula viscosus, and carry out saccharification and fermentation. The fermentation time is 7 days, and the temperature is maintained between 25-30°C. During the per...

Embodiment 2

[0053] Material ratio: 10% almond, 10% black sesame, 15% coix seed, 15% pea, 15% kidney bean, 3% capillary, 3% chrysanthemum, 10% wax gourd, 10% chayote, 3% Alisma, wolfberry 3%, licorice 3%;

[0054] Probiotics: Monascus, Rhodotorula viscosus, Bacteroides albicans, Brettanomyces, Streptomyces agglomerans, Streptomyces nigerogenes, Kluyveromyces lactis, and Streptococcus lactis.

[0055] (A1), soak almonds, black sesame and coix seed in water for 18 hours;

[0056] (A2), put the materials after step A1) into the fermentation kettle, put into Monascus, Rhodotorula viscosus, Brettanomyces, Streptomyces agglomerans, Streptomyces nigerogenes, and carry out vinegar fermentation, and the fermentation time is 14 days , the temperature is maintained between 30°C;

[0057] (B1) Grind peas, kidney beans, capillary, chrysanthemum, wax gourd, chayote, Alisma, wolfberry, and licorice into a puree with a grinder, add distilled water, and put it into a glass fermentation kettle....

Embodiment 3

[0064] Ratio of ingredients: 10% almond, 10% mung bean, 15% coix seed, 15% pea, 15% kidney bean, 3% capillary, 3% rose, 10% lettuce, 10% chayote, 3% Alisma, Goji berry 3%, licorice 3%;

[0065] Probiotics: Monascus, Rhodotorula viscosus, Bacteroides albicans, Brettanomyces, Streptomyces agglomerans, Streptomyces nigerogenes, Kluyveromyces lactis, and Streptococcus lactis.

[0066] (A1) Soak almonds, mung bean kernels, and coix seeds in water for 18 hours, steam them in a steamer, and place them in a cool place to cool naturally below 30°C;

[0067](A2), put the materials after step A1) into the fermentation kettle, put into Monascus, Rhodotorula viscosus, Brettanomyces, Streptomyces agglomerans, Streptomyces nigerogenes, and carry out vinegar fermentation, the fermentation time is 14 days, The temperature is maintained between 30°C;

[0068] (B1), crush peas, kidney beans, capillary wormwood, roses, lettuce, chayote, Alisma, wolfberry, and licorice into a puree with a gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com